Quantitative explosive filling mechanism based on surface mine blasting

A technology for filling mechanisms and explosives, applied in blasting, cleaning methods using tools, cleaning methods and appliances, etc., can solve the problems of long conveying distance, time-consuming and labor-intensive, deep blasting depth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

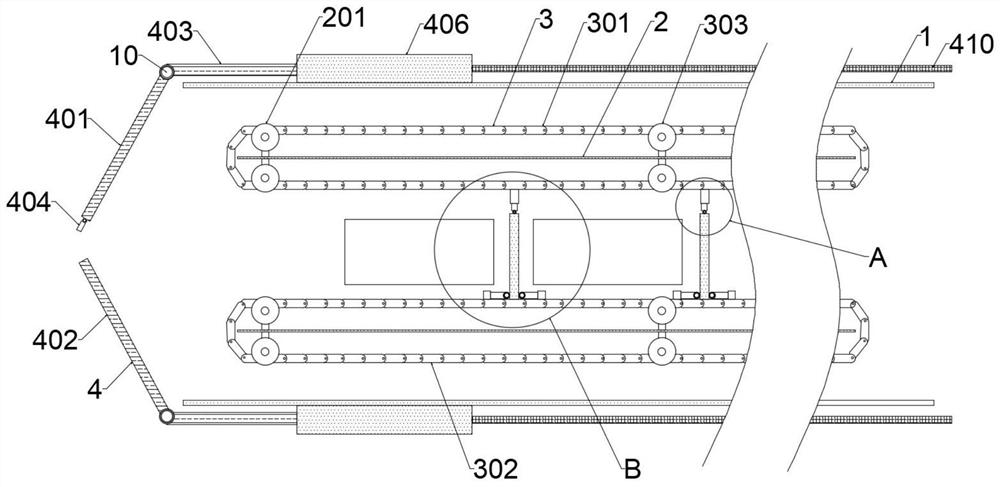

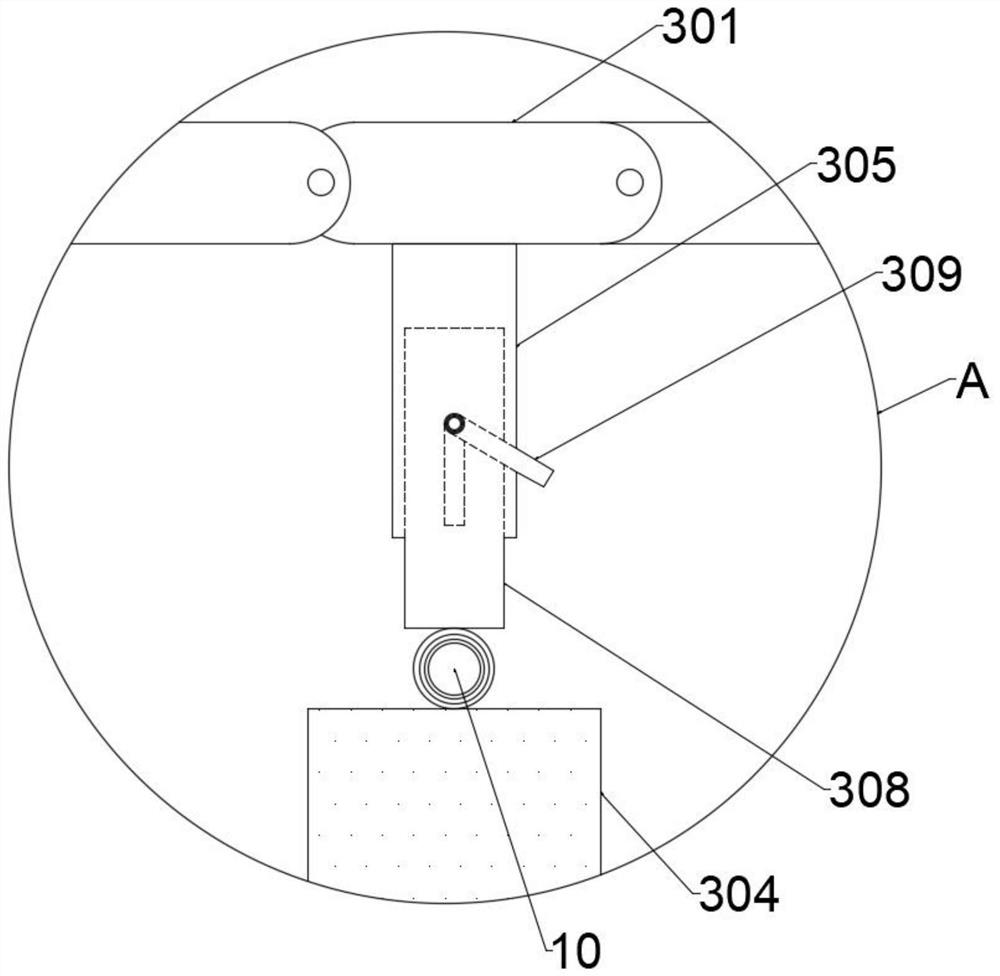

[0035] like figure 1 , image 3 and Figure 4 As shown, according to the length of the explosive package, the distance between adjacent push plates 304 is adjusted. During specific setting, the rotating blocks 307 on both sides of the bottom of the push plate 304 are clamped in the second slot hole of the second mounting block 306, Press the clamping rod 309 inside the short rod 308, so that the clamping rod 309 is clamped in the first slot hole provided at the bottom of the first mounting block 305, and then the pushing plate 304 is fixed. Explosive packs are placed between the first crawler 301 and the second crawler 302, so that the present invention can carry out uninterrupted delivery of explosives according to the actual amount, and solve the problem that due to the deep blasting depth, the delivery distance is long, and the pushing device needs to be withdrawn repeatedly to continue delivery of explosives Time-consuming and labor-intensive problems;

Embodiment 2

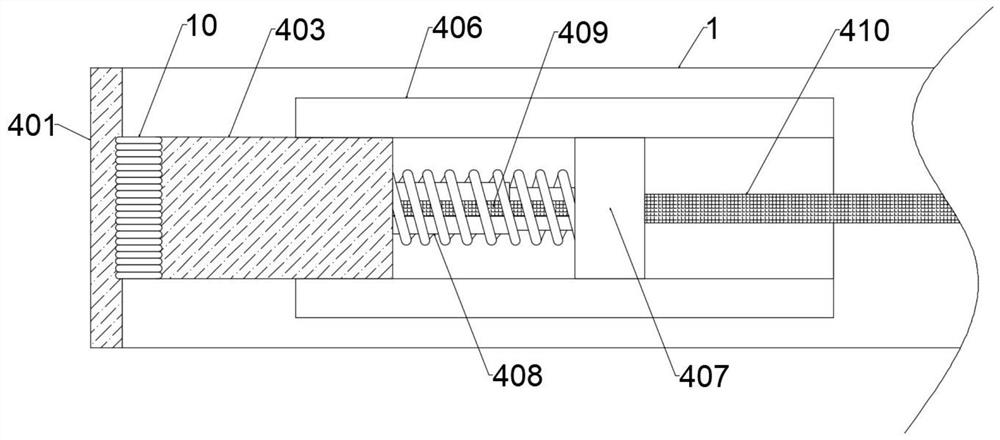

[0037] like Figure 1-4 , Figure 6-8As shown, when the outer gun barrel 1 moves in the blasting borehole, the first baffle plate 401, the second baffle plate 402 and the third baffle plate 403 included in the anti-blasting hole blockage unit 4 protect the outer gun barrel 1, while the first The socket block 404 connected to the baffle plate 401 cooperates with the socket hole 405 provided by the second baffle plate 402, so that the first baffle plate 401 and the second baffle plate 402 can push the gravel and earth slag in the blasting borehole to the outside. While on both sides of the gun barrel 1, ensure that the outer gun barrel 1 enters smoothly, the first baffle plate 401 and the second baffle plate 402 will not be opened by gravel and earth slag, and also prevent the outer gun barrel 1 from flowing into the gravel and The earth slag causes blockage, which affects the delivery of the explosive package. When the outer gun barrel 1 moves to the bottom of the blasting bor...

Embodiment 3

[0040] like figure 1 and Figure 5 As shown, the second guide wheel 303 is driven by an external motor, so that the first track 301 and the second track 302 move outside the first guide wheel 201 and the second guide wheel 303, and the first track 301 and the second track 302 drive the push The plate 304 moves to push the explosive package into the blasting borehole. At the same time, the rotating block 307 is released from the second slot hole by the action of the torsion spring 10, and then by the action of the short rod 308, the push plate 304 is turned over and placed in the outer gun barrel. 1 and the inner gun barrel 2 to move in the gap to ensure that the rear push plate 304 can push the explosives smoothly, and at the same time, the roller 5 is affected by the second telescopic rod 501, and the lead wire connected to the explosive package is directional conveyed to ensure that the lead wire will not be twisted. Agglomeration causes breakage, which solves the problem t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com