Cleaning nozzle, cleaning equipment and cleaning method of cover plate

A technology for cleaning nozzles and cleaning equipment, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., which can solve the problems of cover glass coating damage and insufficient cleaning of the arc part of the cover glass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Terms used in the embodiments of the present application are only for the purpose of describing specific embodiments, and are not intended to limit the present application. The singular forms "a", "said" and "the" used in the embodiments of this application and the appended claims are also intended to include plural forms unless the context clearly indicates otherwise.

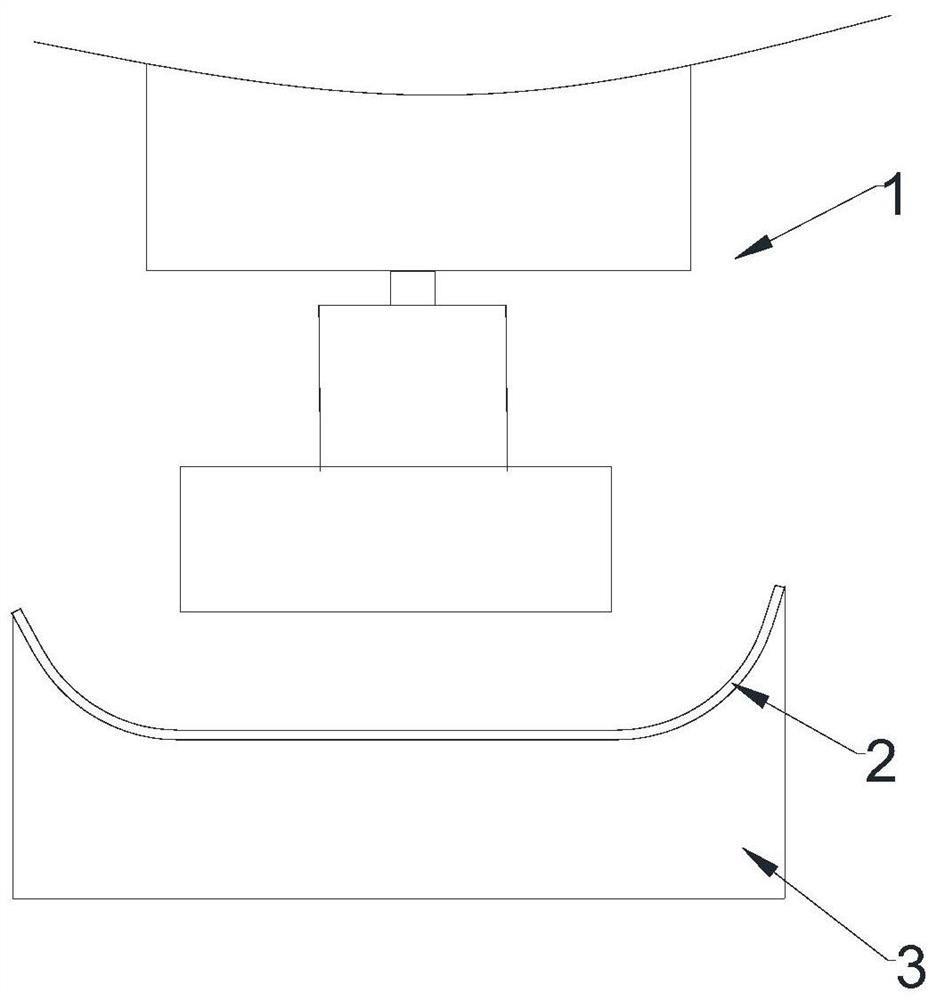

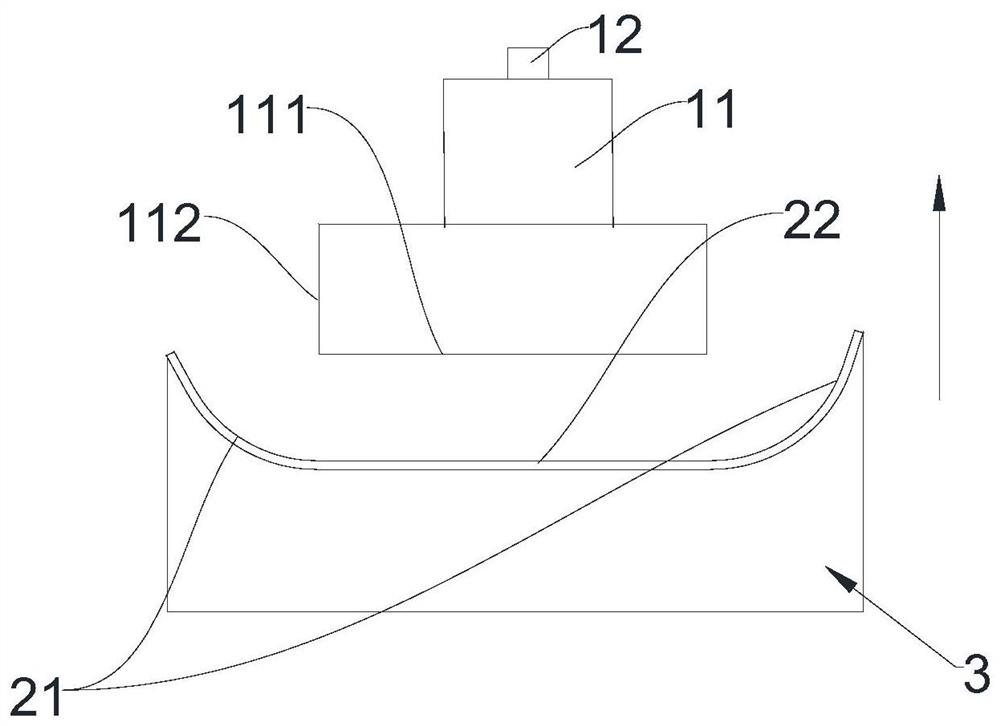

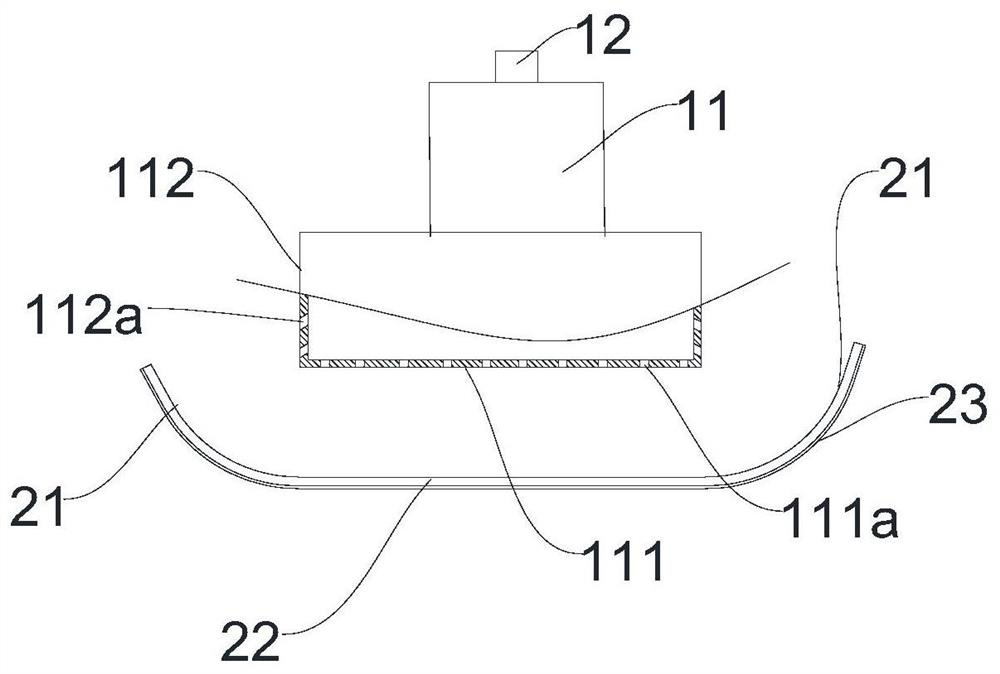

[0055] An embodiment of the present application provides a cleaning device, such as figure 1 As shown, it is used to clean the cover 2. The cover 2 is generally a glass cover. With the emergence of curved screens, in order to ensure a good bonding effect between the cover 2 and the display panel, there will be corresponding The position is curved to fit better with the display panel, so as to achieve a better effect of curved screen or ring screen.

[0056] In this kind of structural fit, since the cover plate 2 has a curved arc position, before the cover plate 2 is bonded to the display panel, it is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com