Method for increasing propylene yield and gasoline yield through high-selectivity catalytic cracking

A catalytic cracking, high-selectivity technology, applied in chemical instruments and methods, molecular sieve catalysts, production of bulk chemicals, etc., can solve problems such as less reports on ethylene and propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0179] Example 1 illustrates the effects of increasing propylene production and gasoline production during the process of the highly selective catalytic cracking method for increasing propylene production and increasing gasoline production provided by the present disclosure.

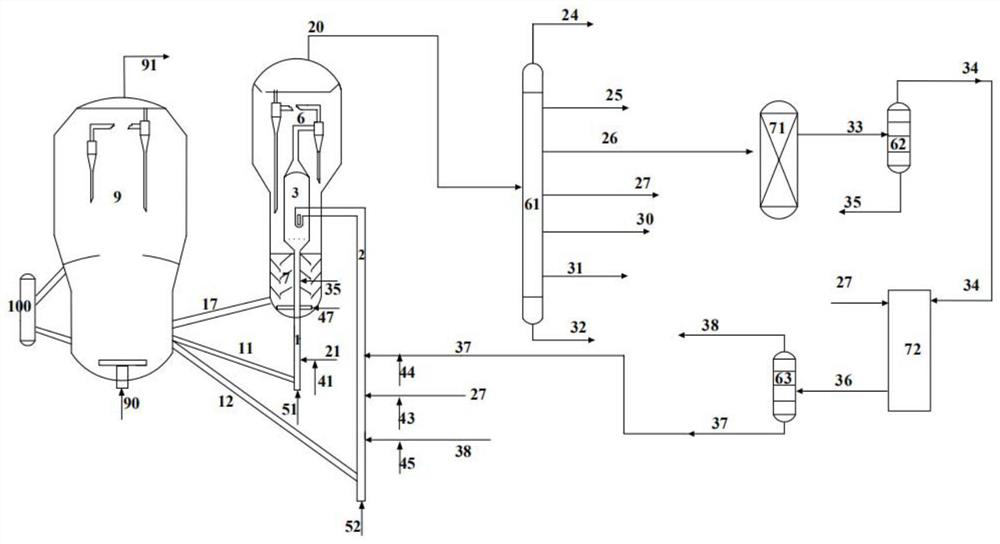

[0180] Experiments were carried out using a medium-sized device with three reactors for continuous reaction-regeneration operation, where the heavy oil cracking reactor was a riser, and the inner diameter of the riser reactor was 16 mm and the height was 3800 mm. The light hydrocarbon cracking reactor is a riser reactor with an inner diameter of 16 mm and a height of 3200 mm. The outlet of the first riser reactor and the second riser reactor is introduced into the fluidized bed reactor as an enhanced catalytic conversion reactor. The inner diameter of the fluidized bed reactor is 64 mm and the height is 300 mm.

[0181] The first catalytic cracking catalyst is the first regenerated catalyst with a temper...

Embodiment 2

[0204] Example 2 illustrates the effects of increasing propylene production and gasoline production during the process of the highly selective catalytic cracking method provided by the present disclosure for increasing propylene production and gasoline production.

[0205] The reaction apparatus that adopts is with embodiment 1. The main experimental steps are the same as in Example 1. The weight ratio of olefin-depleted recycle stream (-12~5℃) to heavy feedstock is 0.1:1. The weight ratio of light gasoline (9-120°C) to heavy raw material is 0.3:1. The weight ratio of multi-branched olefin products (100-130°C) to heavy feedstock is 0.11:1. The weight ratio of highly cracked olefin products (170-300°C) to heavy raw materials is 0.09:1.

[0206] In embodiment 2, only the isobutene-poor C4 flow fraction is introduced into a high-cracking olefin synthesis reactor to undergo superposition reaction, and the second synthesis product oil gas is obtained, which is further introduced...

Embodiment 3

[0210] Example 3 illustrates the effects of increasing propylene production and gasoline production during the process of the highly selective catalytic cracking method provided by the present disclosure for increasing propylene production and gasoline production.

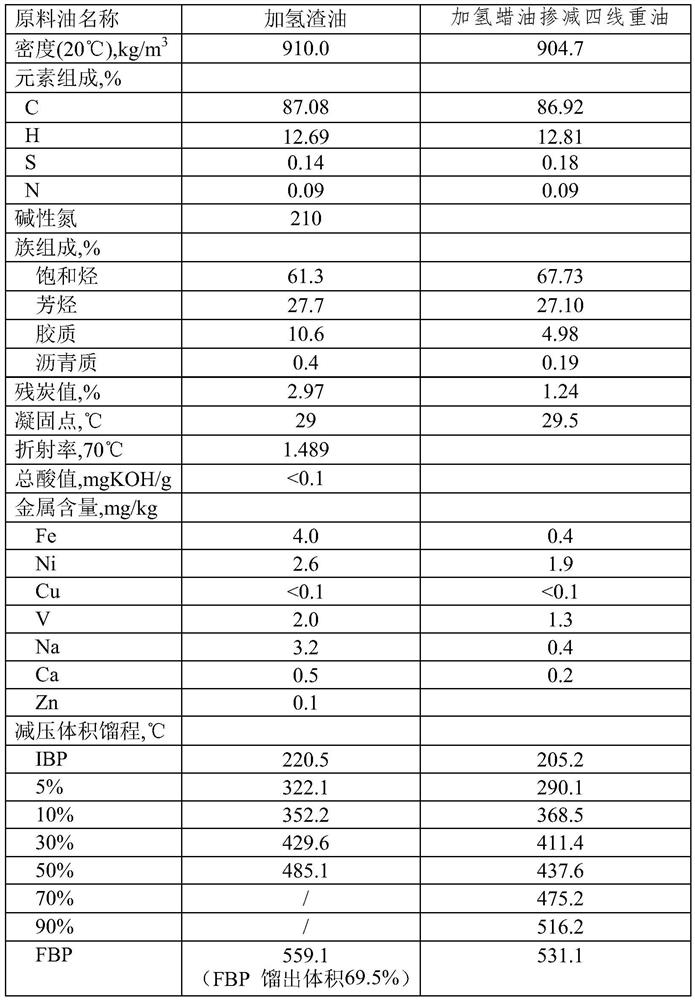

[0211] The reaction apparatus that adopts is with embodiment 1. The main experimental steps are the same as in Example 1, except that the heavy raw material selected is a mixed raw material of hydrogenated wax oil mixed with four-line heavy oil. The main operating conditions and results are listed in Table 3.

[0212] Table 1-1

[0213] Catalyst name OMT-plus Chemical properties, wt% Al 2 o 3

53.5 P 2 o 5

2.35 RE 2 o 3

0.81 physical properties Total pore volume,ml / g 0.20 Micropore volume,ml / g 0.02 Specific surface, m 2 / g

139 Pore area, m 2 / g

109 Matrix specific surface, m 2 / g

38 Bulk density, g / ml 0.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com