Method for prolonging service life of cured felt

A life-span and heating-curing technology, which is applied in the treatment of textile materials, coatings, mechanical cleaning, etc., can solve problems such as abnormal use, decreased thermal insulation performance, and oxidized felt, so as to prolong the service life, improve the service life, and remove The effect of dust and lint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

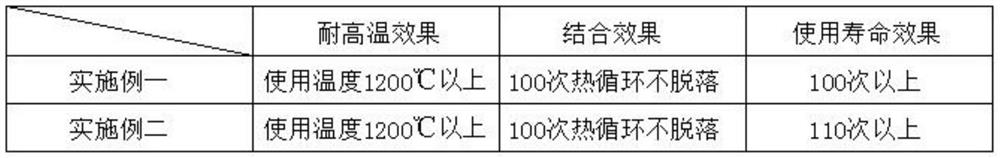

Examples

Embodiment 1

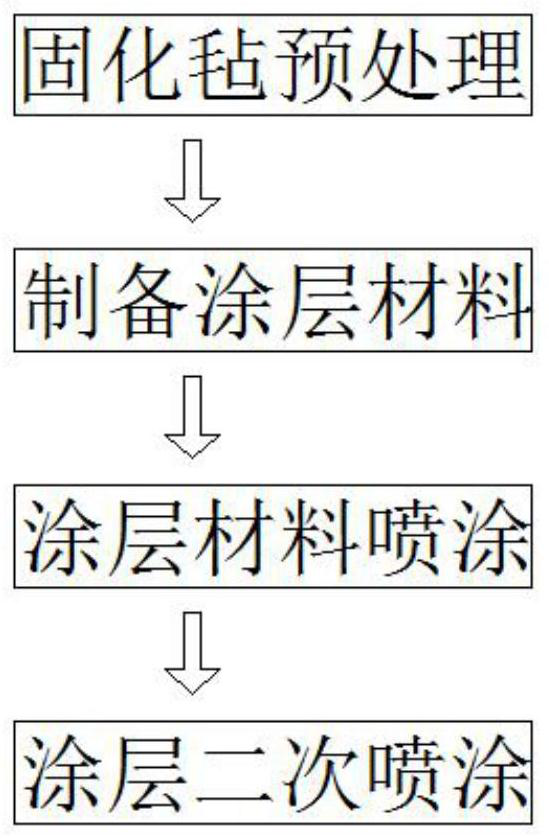

[0026] according to figure 1 As shown, the present embodiment proposes a method for prolonging the service life of the solidified felt, comprising the following steps:

[0027] Step 1: Curing Felt Pretreatment

[0028] Soak the prepared cured felt in advance, dry it in an oven after soaking, and then use high-pressure gas to wash the dried cured felt to blow off the broken fiber debris on the surface. Rinse each surface for 2 times, then soak, then use an oven to dry after soaking, and cool after drying to obtain a cleaned solidified felt. The soaking time in the step 1 is 20 minutes, and it is carried out at room temperature. Soaking, the drying time in the step 1 is 20 minutes, and the drying temperature is 60 degrees Celsius;

[0029] Step 2: Prepare the coating material

[0030] Stir and mix silicon carbide, graphite powder, curing agent, silicone resin, and organic solvent through a reaction kettle, mix evenly to obtain a coating material, then pour it into a container...

Embodiment 2

[0036] according to figure 1 As shown, the present embodiment proposes a method for prolonging the service life of the solidified felt, comprising the following steps:

[0037] Step 1: Curing Felt Pretreatment

[0038] Soak the prepared cured felt in advance, dry it in an oven after soaking, and then use high-pressure gas to wash the dried cured felt to blow off the broken fiber debris on the surface. Rinse each surface for 3 times, then soak, then use an oven to dry after soaking, and cool after drying to obtain a cleaned solidified felt. The soaking time in the step 1 is 30 minutes, and it is carried out at room temperature. Soaking, the drying time in the step 1 is 15 minutes, and the drying temperature is 70 degrees Celsius;

[0039] Step 2: Prepare the coating material

[0040] Stir and mix silicon carbide, graphite powder, curing agent, silicone resin, and organic solvent through a reaction kettle, mix evenly to obtain a coating material, then pour it into a container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com