Waste wire collecting device for Internet of Things communication construction

A waste wire and collection device technology, applied in the field of Internet of Things communication, can solve the problems of time-consuming, labor-intensive, and unreusable line stripping, etc., and achieve the effect of improving stripping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

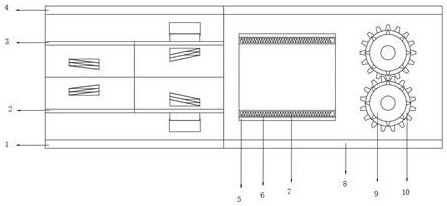

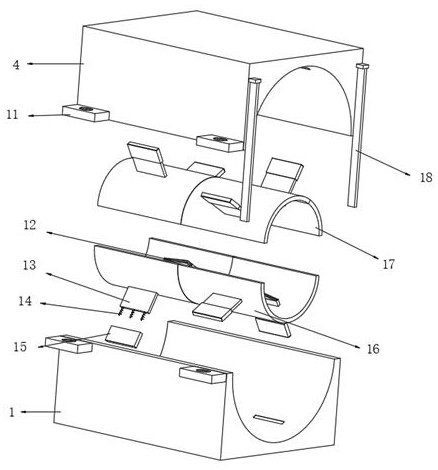

[0027] refer to Figure 1-3 , a waste wire collection device for Internet of Things communication construction, including a first bottom box 1, a first bottom cylinder 2, a scraper 12 and a crushing box 8, a first top box 4 is placed on the top outer wall of the first bottom box 1, and The top and bottom outer walls of the first bottom box 1 and the first top box 4 are hollow semicircular pipe structures, and the outer walls at both ends of the first bottom box 1 and the first top box 4 are provided with fixing mechanisms. The first bottom box 1 and the first top box 4 The top of the first top box 4 and the outer wall of the bottom are all provided with a scraping mechanism, and both sides of an end outer wall top of the first top box 4 are welded with a top sheet, and the bottom outer wall of the top sheet is welded with clamping plates 18, broken box 8 Both sides of one end of the outer wall are provided with a draw-in groove compatible with the clamping plate 18, one end of...

Embodiment 2

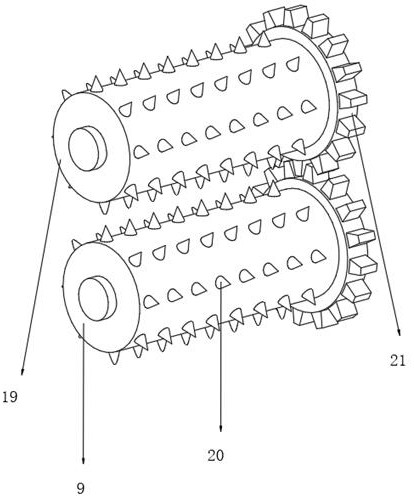

[0035] refer to Figure 4 , a waste wire collection device for Internet of Things communication construction. Compared with Embodiment 1, this embodiment is welded with crushing heads 20 distributed equidistantly on the outer peripheral walls of the main drum 9 and the auxiliary drum 19, and the crushing heads 20 are conical. The peripheral outer walls of the main drum 9 and the auxiliary drum 19 are welded with extruding rods 22 distributed equidistantly, and the top outer walls of the extruding rods 22 are hemispherical.

[0036] Working principle: When in use, when the crushing head 20 is recycling and stripping waste wires, although the conical design increases the stripping effect, it may also cause damage to the internal circuits of waste wires. At this time, through the hemispherical Extruding the rod 22 can solve this problem well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com