Wind power generation device with roof reinforced concrete frame

A technology of wind power generation equipment and reinforced concrete, which is applied in the direction of wind power generator components, wind power engines, and wind power motor combinations, etc., and can solve problems such as poor wind gathering ability of the air gathering door, inflexible opening and closing of the air discharge door, and poor rigidity of the supporting frame structure, etc. , to achieve the effect of improving the utilization rate of wind energy, overcoming the frequent failure of limit switches and high verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

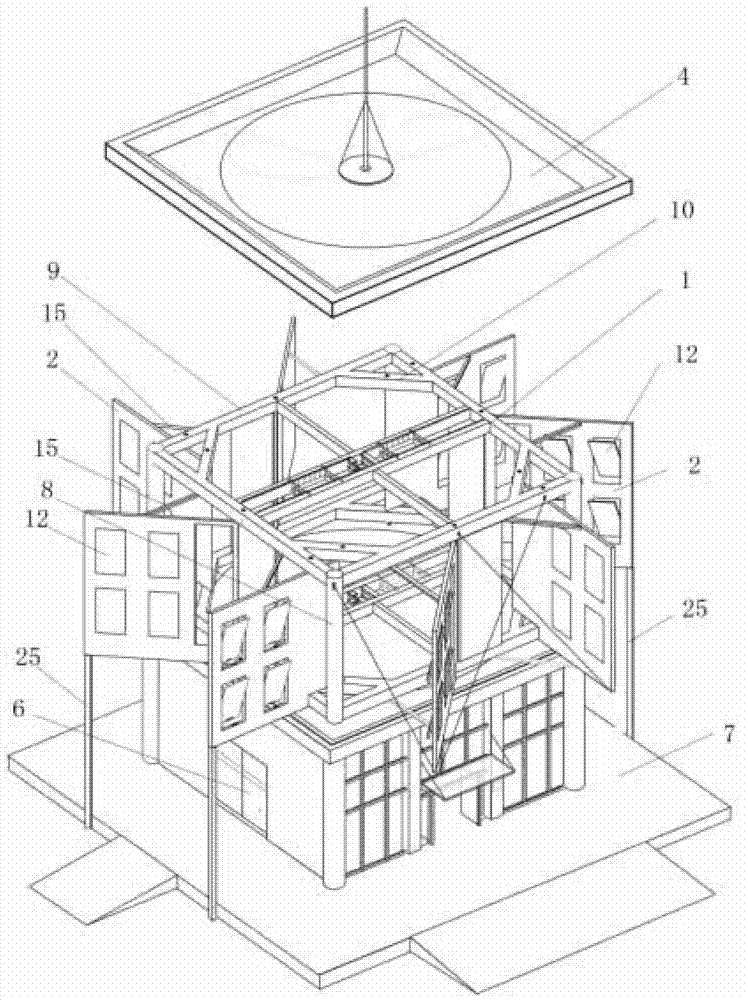

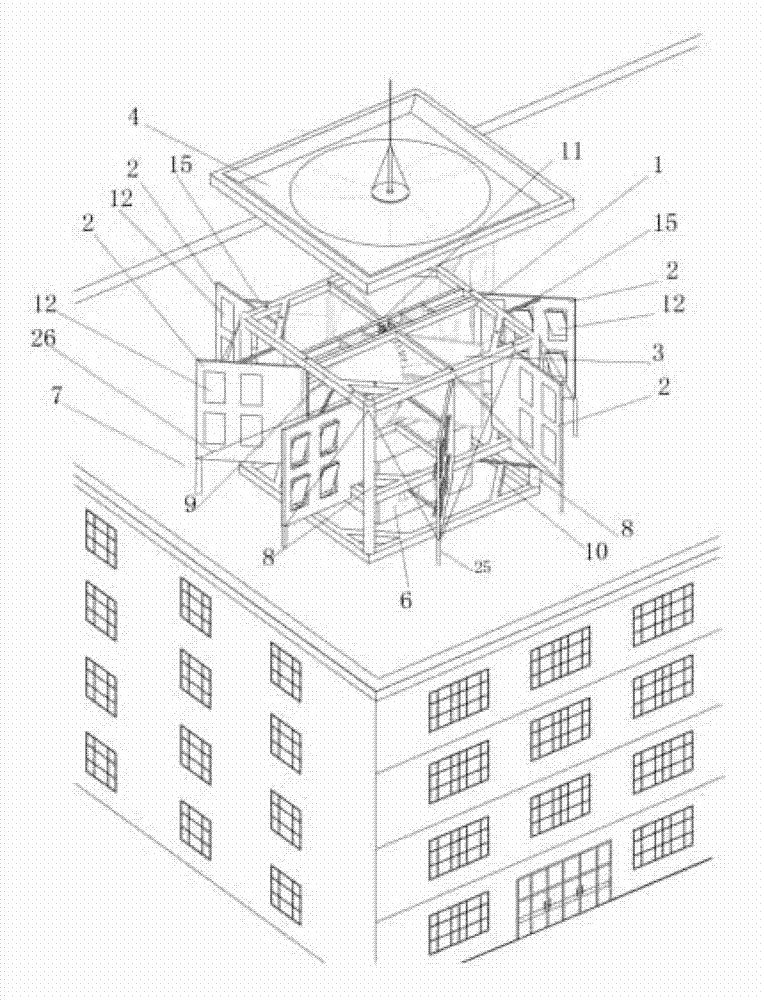

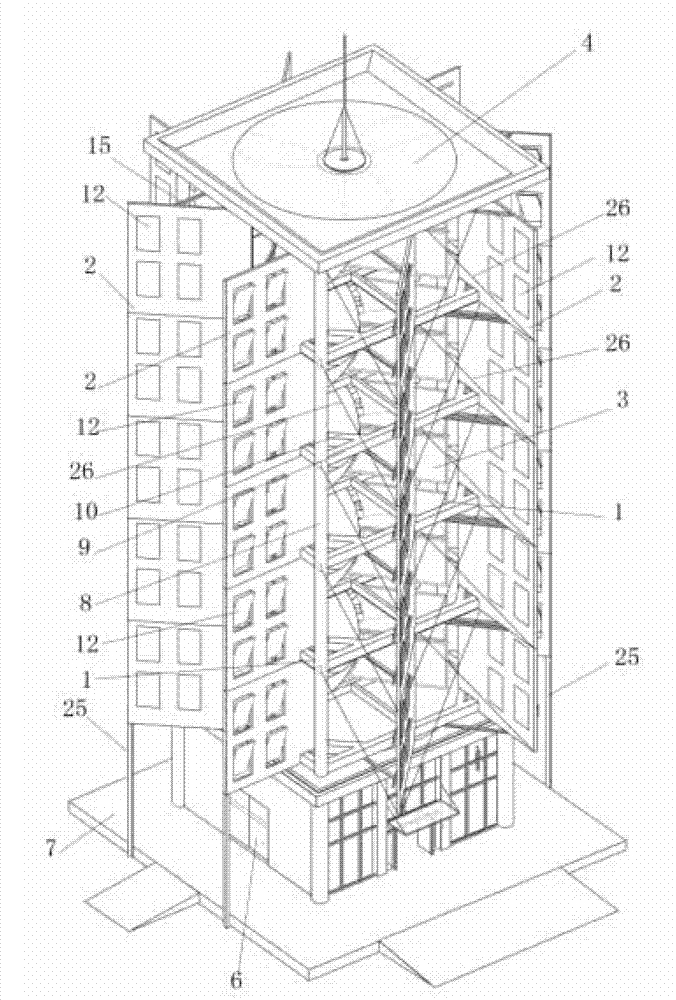

[0052] Specific implementation mode one: combine figure 1 , figure 2 , Figure 5-Figure 15 and Figure 18 Describe this embodiment, the roof reinforced concrete frame wind power generation equipment of this embodiment includes a reinforced concrete frame 1, eight wind deflectors 2, a wind power system 3, a top cover 4, a generator 5, a control room 6 and base platform 7,

[0053] The reinforced concrete frame 1 includes four reinforced columns 8, two four-sided beams 9, a plurality of cable-stayed beams 10 and two cross machine bearing beams 11;

[0054] Two four-sided beams 9 are set up and down, and the edges and corners of the two four-sided beams 9 are connected by reinforcing columns 8. Each four-sided beam 9 is provided with a cross machine bearing heavy beam 11, and each cross machine bearing heavy beam 11 is formed by a single beam 11 -1 and a double beam 11-2, each corner of the four-sided beam 9 is connected with a cable-stayed beam 10;

[0055] The reinforced ...

specific Embodiment approach 2

[0062] Specific implementation mode two: combination Figure 6 Describe this embodiment, the extension line 21 of the upper connecting end and the lower connecting end of the eight air discharge deflectors 2 of this embodiment and the motion locus circle 22 intersection point 23 of the wind blade 19 is the eighth of the motion locus circle of the wind blade 19. At the equal point, the angle A formed between the extension line 21 and the tangent line 24 passing through the intersection point 23 is 45 degrees to 50 degrees, and the adjacent two wind deflectors 2 are set at an angle of 45 degrees, and adjacent Among the two wind deflectors 2, the wind deflector near the edges and corners is perpendicular to the beam plate 9-1 of the four-side beam 9 on the side where it is installed, and the other of the adjacent two wind deflectors 2 The wind guide plate is positioned at the middle position of the beam plate 9-1 of the four side beam 9 on the installation side. Such setting can...

specific Embodiment approach 3

[0063] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the roof reinforced concrete frame wind power generation equipment of this embodiment also includes six support columns 25 and two sets of tie bars 26, and the two wind-discharging guides on the front of the roof reinforced concrete frame wind power generation equipment The plate 2 is connected with the reinforcement column 8 and the four side beams 9 through two sets of tie bars 26 , and the bottom outer edge of the rest of the wind deflector 2 is supported on the ground through a support column 25 . Such arrangement prevents the wind deflector 2 from dropping corners, and the installation structure of the wind deflector is more stable, especially suitable for high-power wind power generation equipment in which the base platform 7 is set on the ground. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com