Landfilling pool for hazardous solid waste

A technology for hazardous solids and wastes, which can be used in the removal of solid wastes, grain processing, etc., and can solve the problems of inaccessibility and aggregation of solid wastes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] as attached figure 1 to attach Figure 6 Shown:

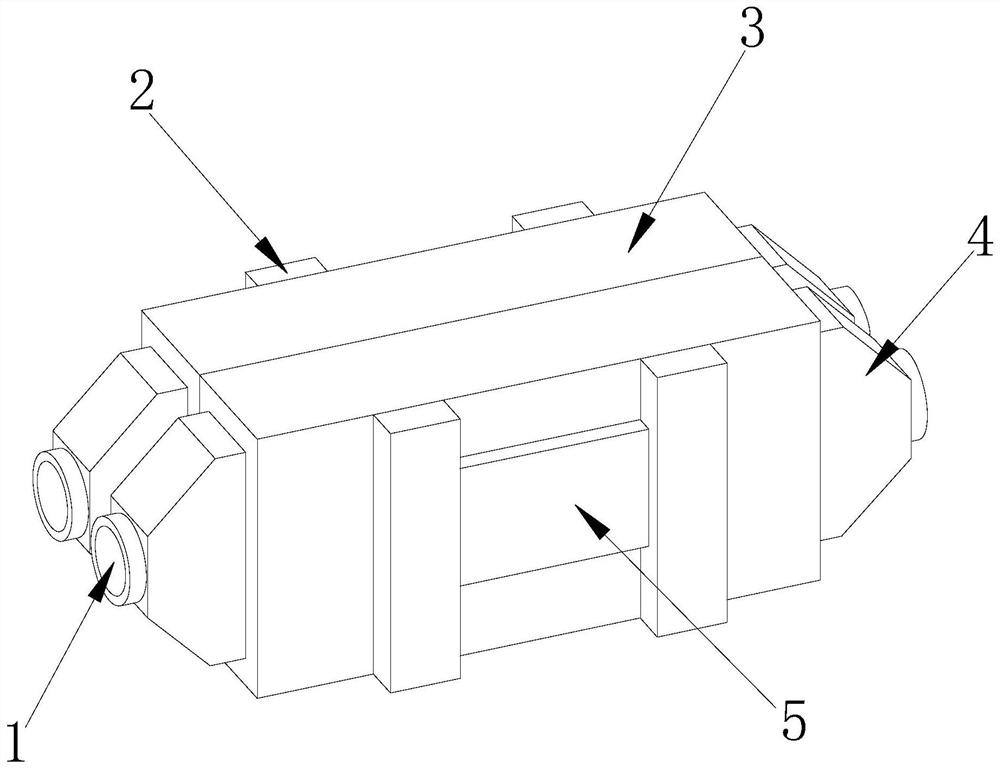

[0031] The present invention provides a landfill pool for hazardous solid waste, the structure of which includes a conveying pipe 1, a fixing frame 2, a transmission box 3, a connecting box 4, and a fixing plate 5, and the inner side of the conveying pipe 1 is welded and connected to the outer side of the connecting box 4 The inner side of the fixed frame 2 is fixedly connected to the outer side of the transmission box 3, the outer side of the transmission box 3 is connected to the inner side of the connection box 4 by studs, and the outer side of the fixed plate 5 is riveted connected to the inner side of the fixed frame 2.

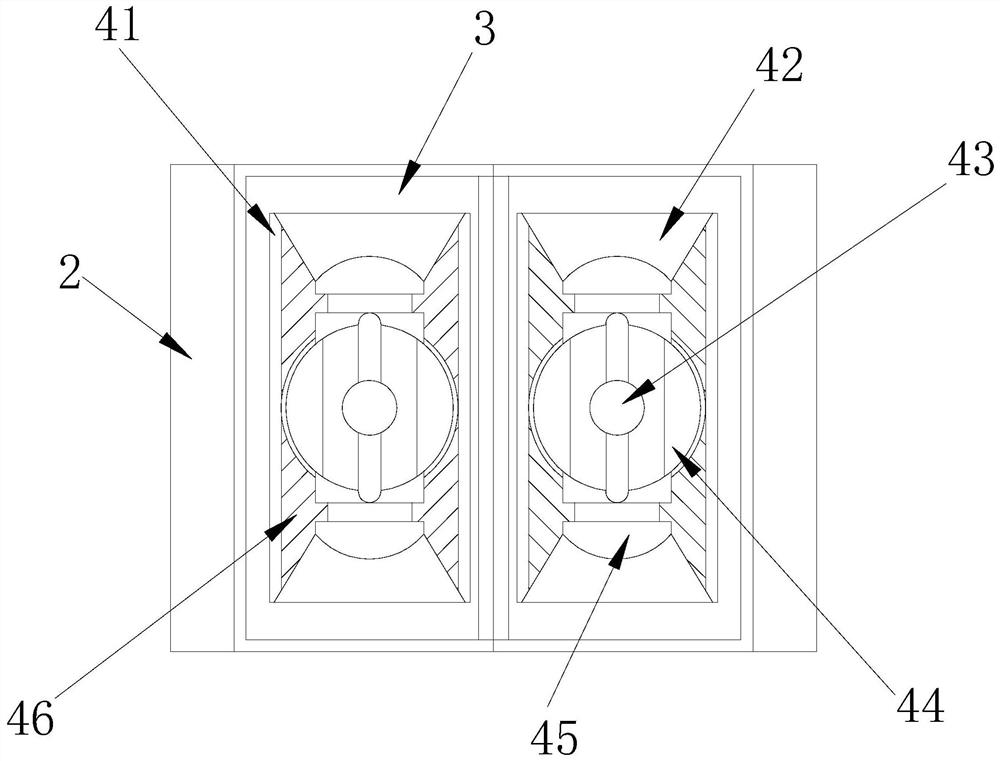

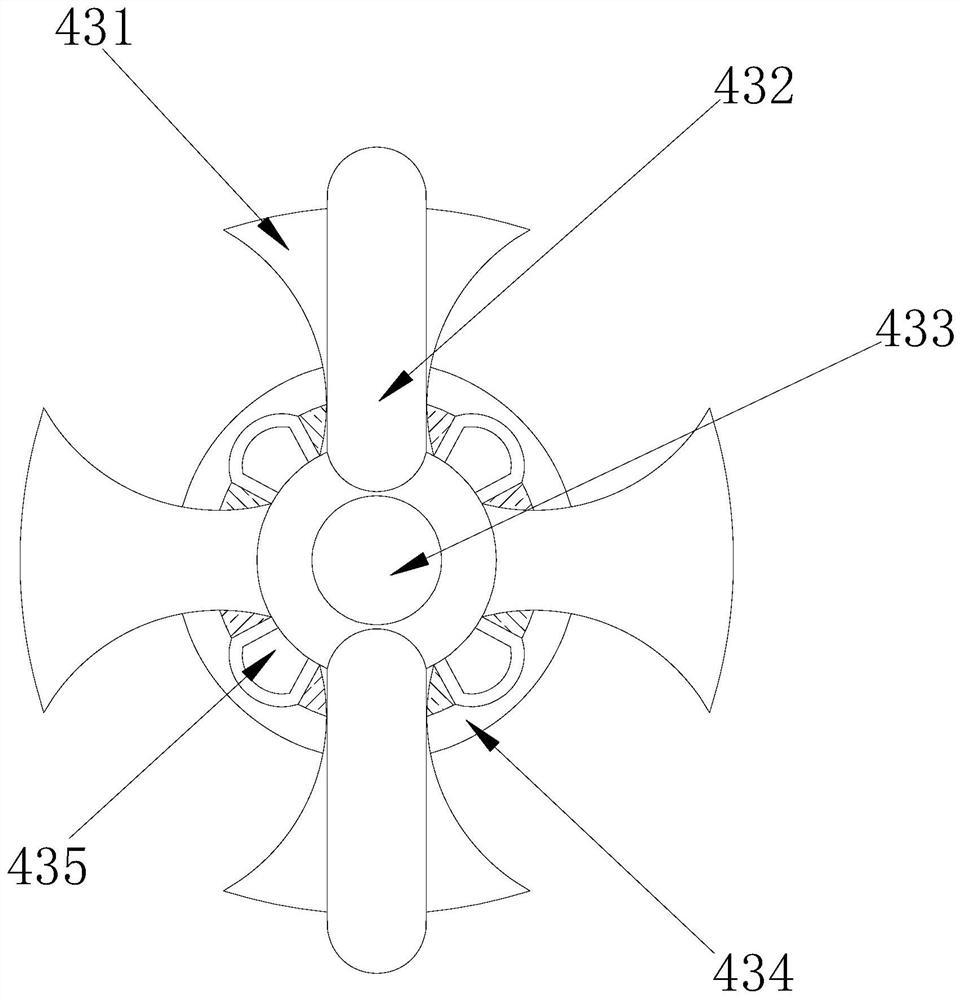

[0032] Wherein, the connection box 4 is provided with a support frame 41, a splint 42, a cutting device 43, a scraping device 44, a connecting column 45, and a support plate 46, the inside of the support frame 41 is fixed to the outside of the splint 42, and the splint 42 is riveted with the oute...

Embodiment 2

[0040] as attached Figure 7 To attach Figure 9 Shown:

[0041] The present invention provides a landfill pool for hazardous solid waste. The scraper 44 is provided with a scraper 441, a connecting ring 442, a clamp 443, a clamping rod 444, and a connecting plate 445. The outer side of the scraper 441 is welded. Connected to the inner side of the connecting plate 445, the outer side of the connecting ring 442 is attached to the inner side of the clamping rod 444, the rear end of the clamp 443 is fixed to the front end of the connecting plate 445, and the outer side of the clamping rod 444 is embedded and fixed on the inner side of the scraper 441 , the four clamping rods 444 are arranged vertically and symmetrically, so that the scraper 441 can be kept stable after being in contact with the cutting device 43 .

[0042] Wherein, the scraper 441 is provided with a scraper c1, a clamping block c2, a telescopic column c3, a connecting frame c4, and a top frame c5, the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com