Production process and device for recoverable chemical molecule synthetic material

A technology for synthesizing materials and chemical molecules, which is applied in the production process and device field of recyclable chemical molecule synthetic materials, can solve problems such as pollution, waste of resources and environment, non-compliance, etc., and achieve the effects of wide application range, environmental protection, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

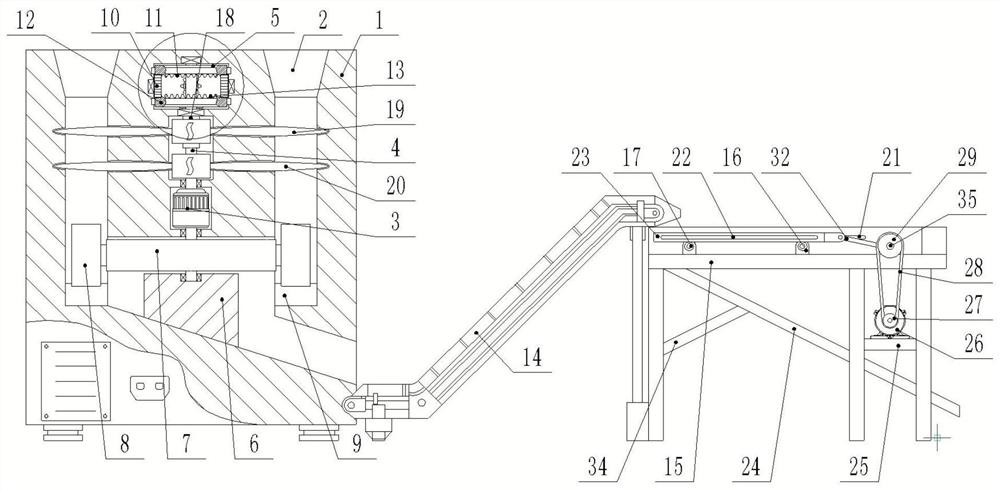

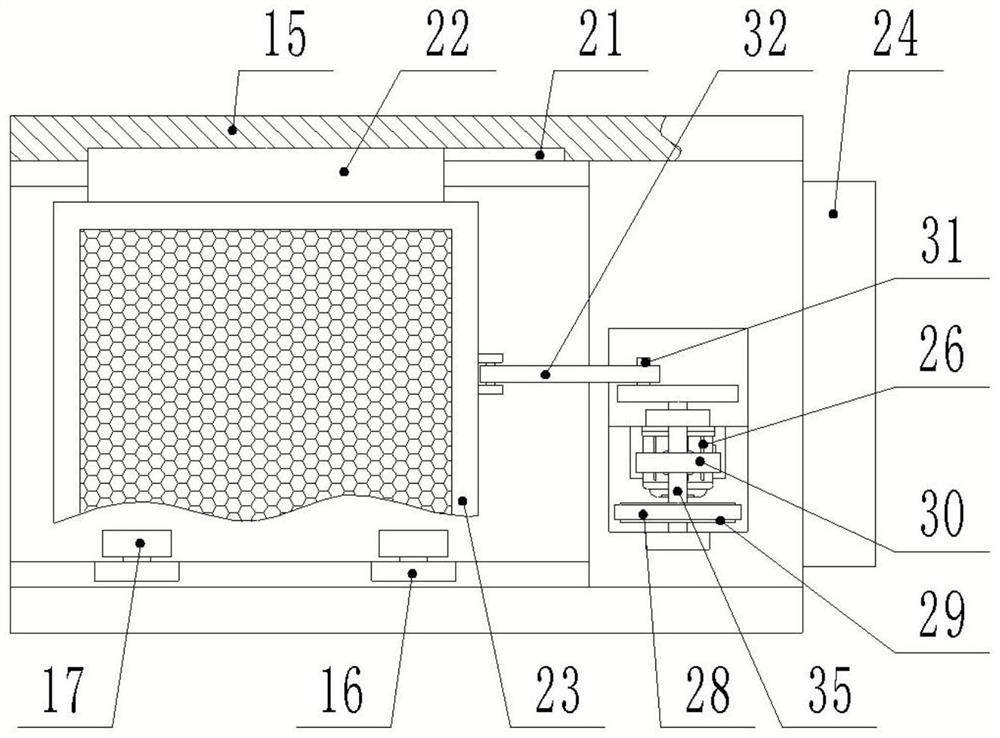

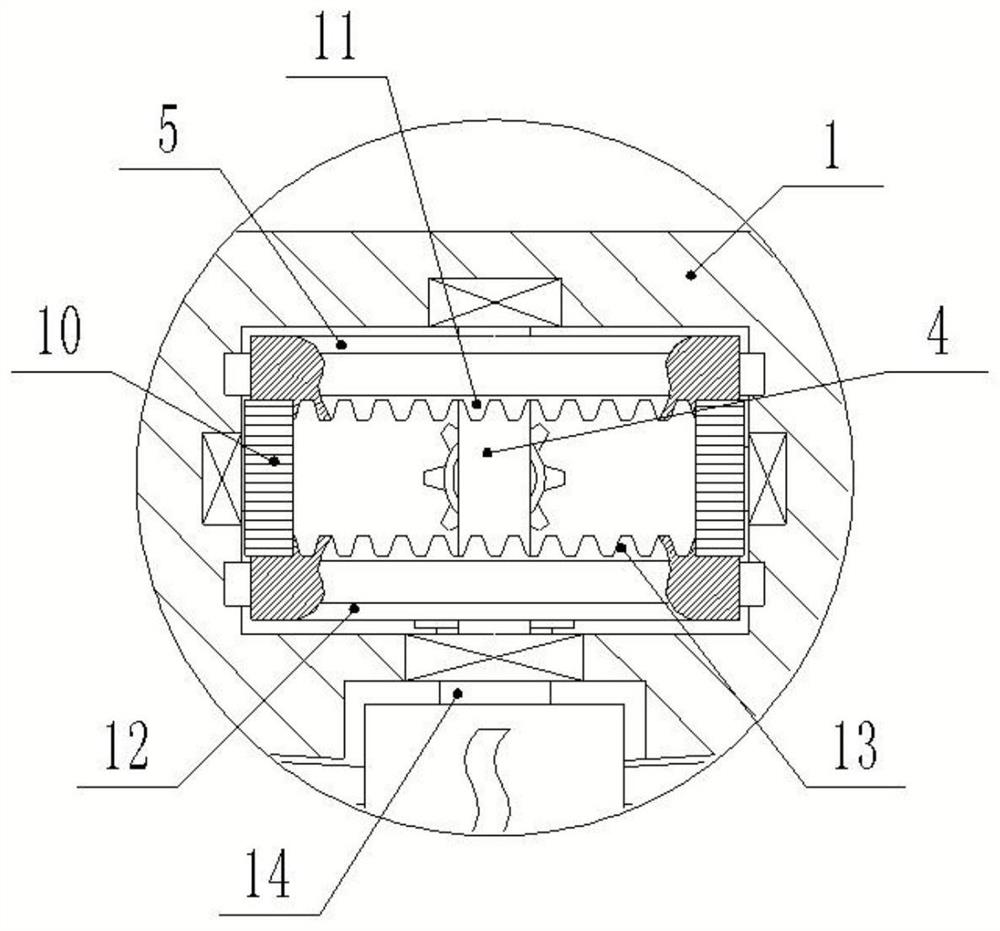

[0037] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5As shown, a production process of recyclable chemical molecular synthesis materials includes the following steps, step S1, material collection, step S2, crushing into crumbs, step S3, scientific processing of different densities, step S4, proportioning fusion, step S5 , pressing the finished product, step S6, into the mold and step S7, the finished product; step S1, pruning the municipal garden ornamental trees during the annual pruning period, recyclable branches, sawdust, wood fiber, resin, adhesive, nutrients required by the plant , anti-ultraviolet dose, and preservatives are recovered; step S2, the residual trees in the step S1 are crushed by the waste utilization device to meet the processing requirements; step S3, the wood chips in the step S2 are processed by the waste utilization device Screening of different densities, and then carry out scientific pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com