Ecological retaining wall wrapping integral reinforced soil and construction method of ecological retaining wall

An ecological retaining wall and integrated technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of poor deformation of slope soil, increased cost, poor drainage of slope soil, etc., and achieve faster The effect of construction speed, landslide reduction and good drainage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

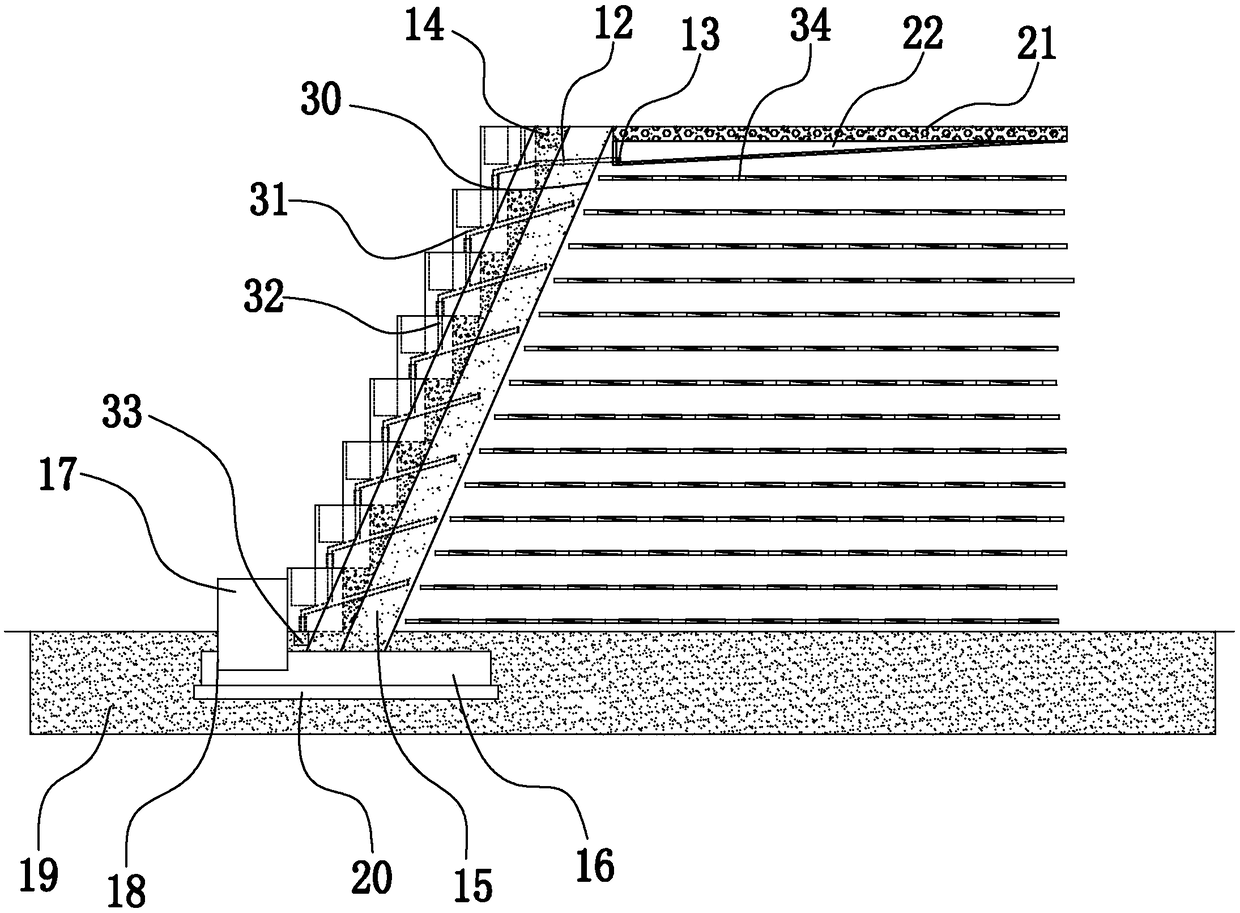

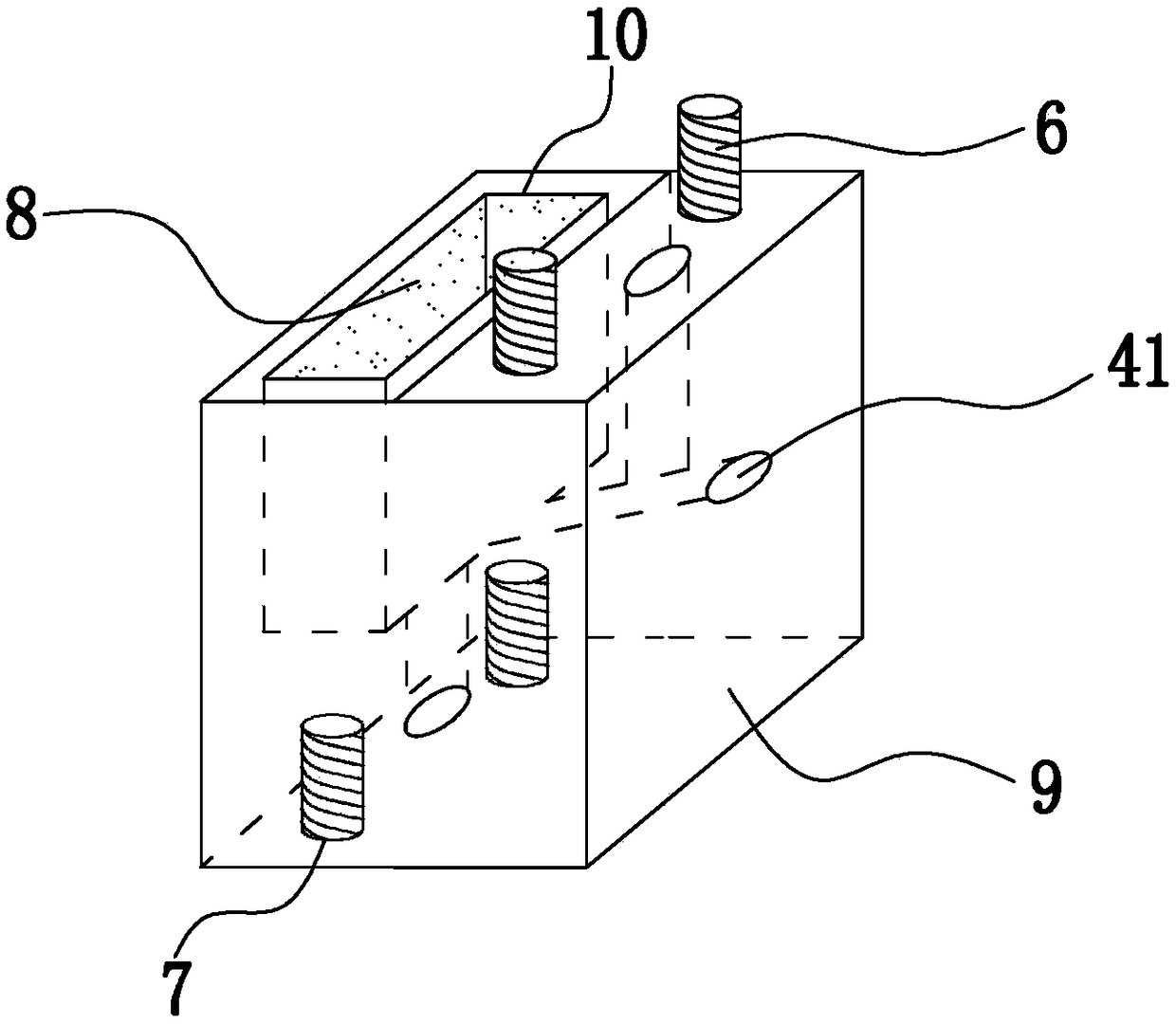

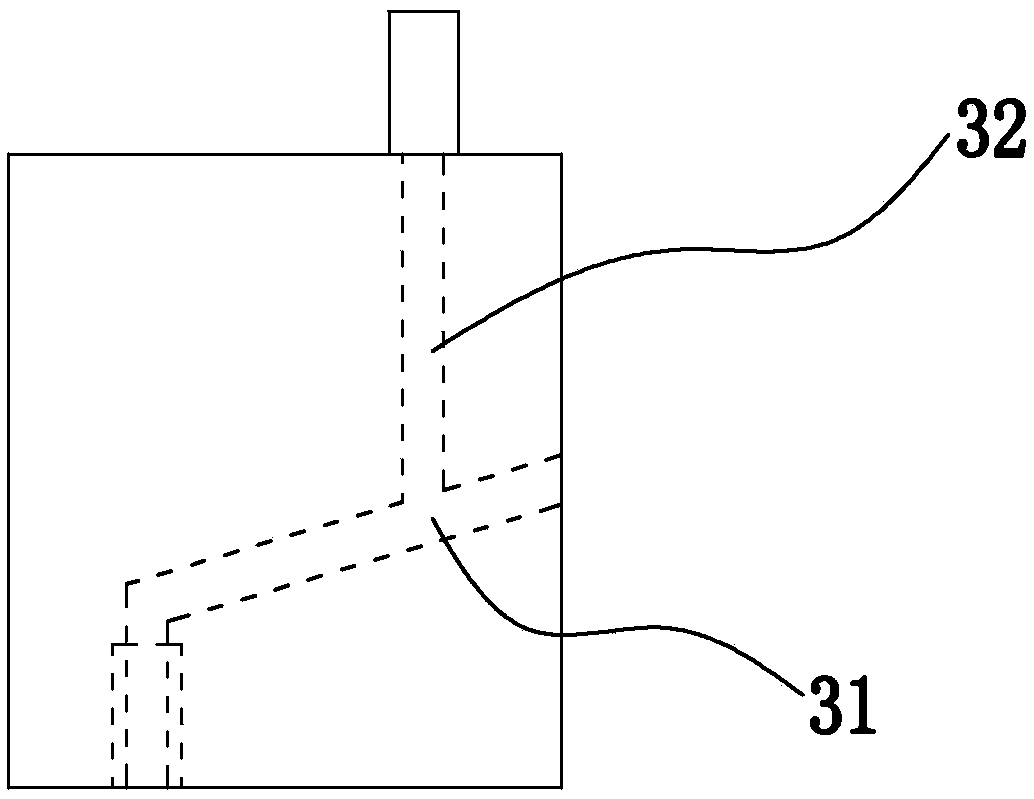

[0039] Example: such as Figure 1-10 As shown, the wrapped integral reinforced soil ecological retaining wall includes a sump 22, a drainage ditch 33 and several blocks 9 arranged on the slope 30; the top of the block 9 is provided with a masonry connecting rod 6, and the block 9 The lower part is provided with a masonry connecting groove 7 corresponding to the masonry connecting rod 6; Reinforced mesh 34 for lateral displacement of slope soil; drainage channels are formed in the block 9, and drainage holes 41 are formed on the outside of the drainage channels; drainage channels include oblique drainage channels 31 and vertical drainage channels 32 .

[0040] The block 9 that the present invention adopts has just been prefabricated outside the construction site, and the block connecting rod 6 of its top matches the block connecting groove 7 of the lower part, and the block connecting rod 6 of the following block 9 is inserted into the upper block. In the block connection gro...

specific Embodiment approach

[0052] The specific embodiment of the present invention comprises the following steps:

[0053] Step (1), the construction of the cushion layer 20 and the foundation 16; excavate a foundation pit with a length of 3.5m and a height of 1.3m at the bottom of the slope. One end of the foundation pit needs to extend 0.9m into the retaining wall, and then Set up the formwork of cushion layer 20, the height of formwork is 0.12m. After the formwork is erected, concrete is poured, and after the concrete is poured, it is maintained until the strength meets the requirements, and then the formwork is removed. Then set up the formwork of foundation on cushion layer 20, the height of foundation formwork is 0.5m, the formwork of foundation erection needs to reserve groove 18, and the width of reserve groove is 0.75m, in order to place retaining stone 17. After the formwork is erected, concrete is poured in the foundation 16 formwork, and after the concrete is poured, it is also maintained u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com