Press-fit device for new material processing and press-fit process of press-fit device

A technology of pressing device and new material, applied in the direction of presses, manufacturing tools, etc., can solve the problems of being easily stuck in the pressing groove, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

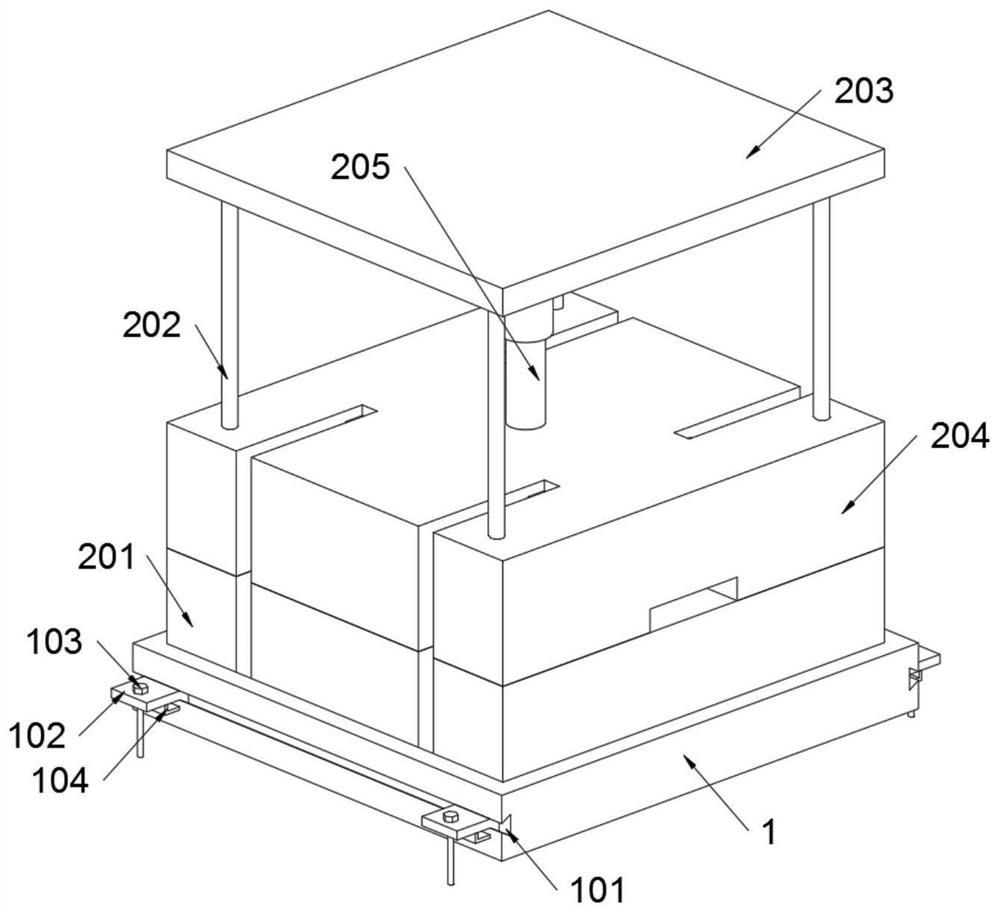

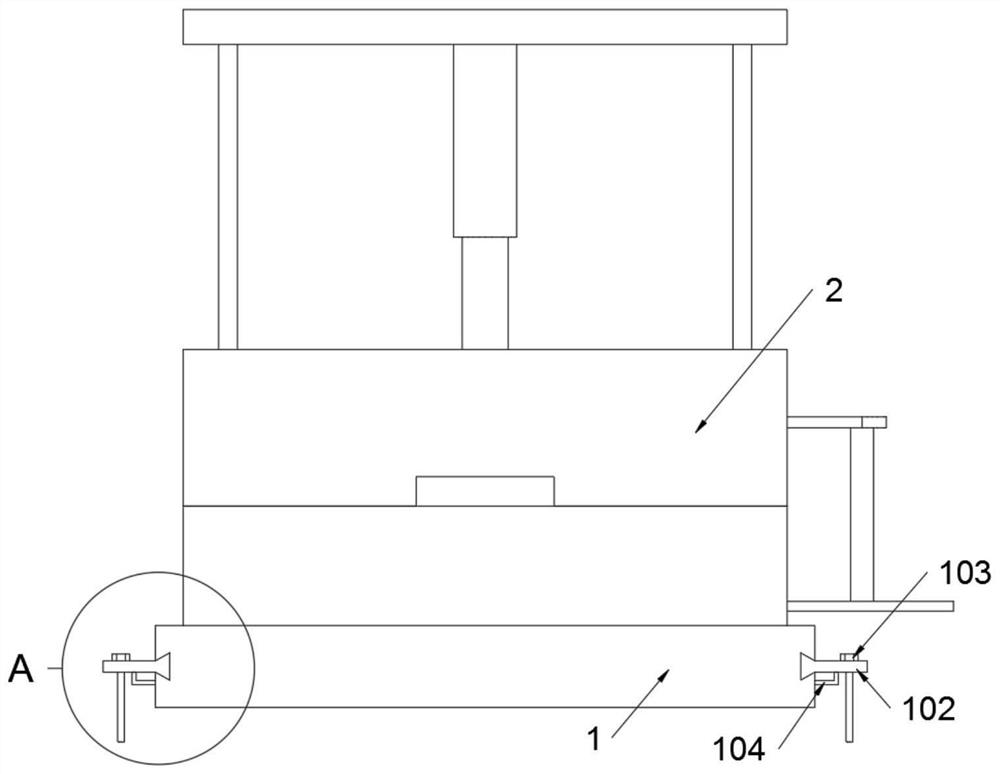

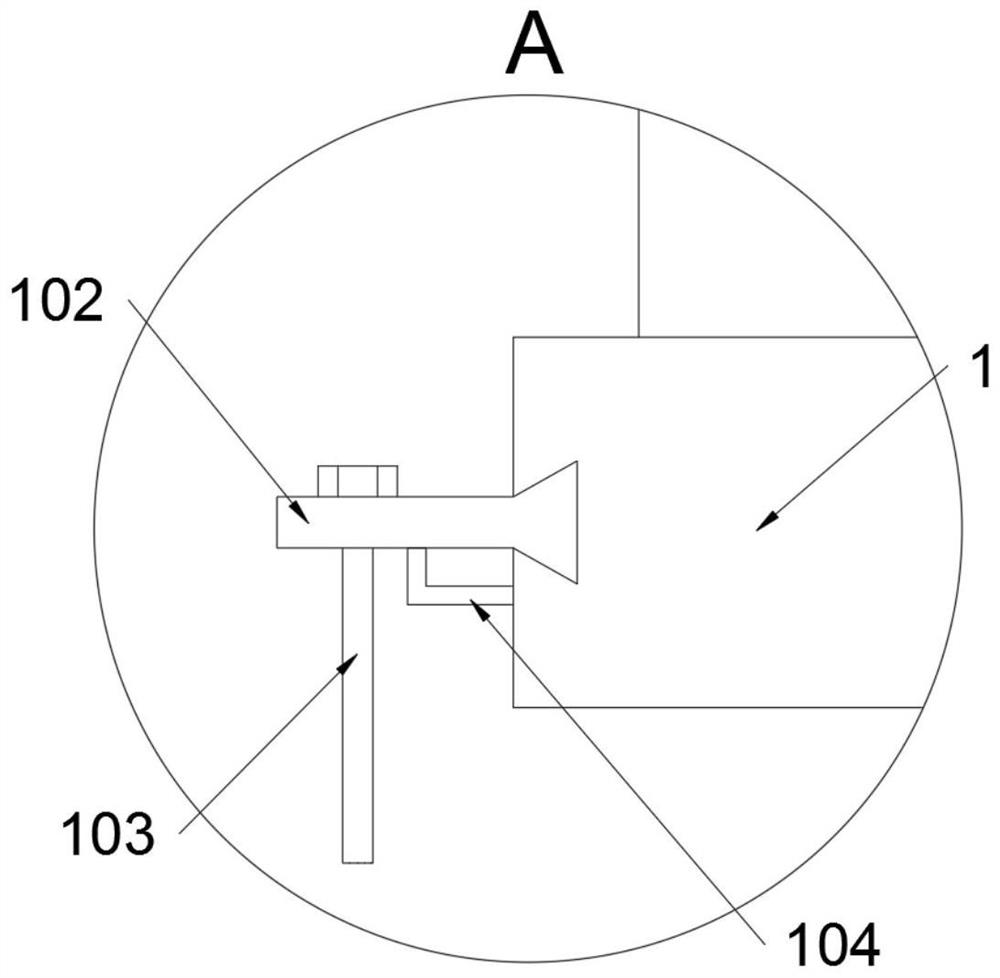

[0048] as attached figure 1 to attach Figure 8 Shown:

[0049] The invention provides a pressing device based on new material processing and its pressing process, including a base 1; the base 1 is a rectangular box-shaped structure, and a pressing part 2 is installed on the base 1; An auxiliary part 3, and a discharge part 4 is installed on the pressing part 2.

[0050] Reference as Figure 7 , the discharge part 4 includes: a sliding rod C401, which is slidably connected to the female base 201, and a retaining ring 402 is welded on the sliding rod C401; an elastic member B403 is sleeved on the sliding rod C401, and the elastic member B403 constitutes The elastic reset structure of the sliding rod C401; the sliding rod C401 is located in the press-fit groove on the female seat 201, so that the elastic upward movement of the sliding rod C401 can be realized through the elastic push of the elastic member B403, thereby realizing unloading.

[0051] Reference as Figure 7 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com