Drainage pipeline fracture defect detection and grade evaluation method

A drainage pipe and defect detection technology, applied in image data processing, instrument, character and pattern recognition, etc., can solve the problems of lack of defect classification method and limited practical application, so as to improve detection efficiency and accuracy, reduce The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

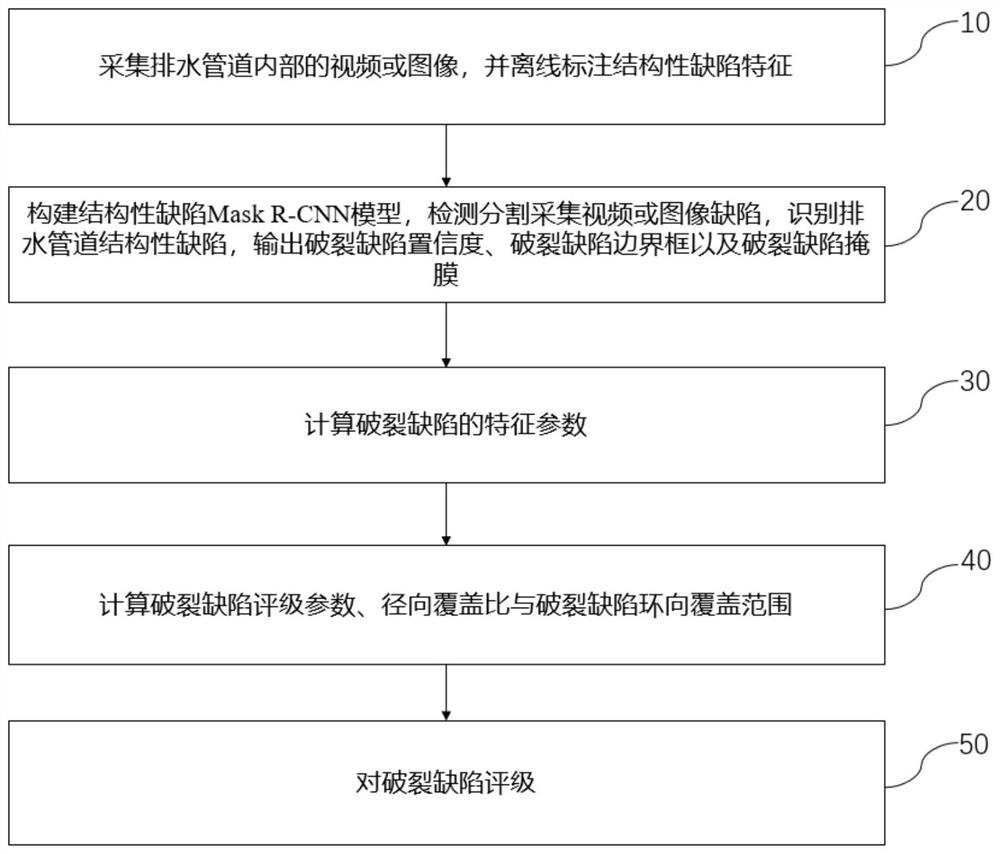

[0051] 【Example 2】If Figure 4 and Figure 6 It is a graphical representation of the detection and recognition of drainage pipe endoscope defects and the mask fitting of drainage pipe defect detection and identification through CCTV; the video or image inside the drainage pipe is collected by CCTV system or pipe periscope, and the structural defect features are marked offline; the structure is constructed Defective Mask R-CNN model, detects segmentation defects in collected videos or images, identifies structural defects in drainage pipes, detects and identifies them as ruptured defects, outputs ruptured defect confidence, ruptured defect bounding box, ruptured defect mask; calculates ruptured defects The characteristic parameters of are as follows:

[0052] Area size S crack =20786, long axis length LL crack =338.8133, minor axis length SL crack =89.9195, eccentricity E crack =0.9641, direction O crack =-74.9815, convex area C crack =26274, filling area F crack =20786...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com