A kind of anti-turnover hammock preparation technology

A preparation process and anti-turnover technology, which is applied in the field of hammocks, can solve problems such as difficulty in stabilizing the center of gravity, unbalanced force on both sides of the hammock body, rollover of the hammock body, etc., so as to avoid turning over and ensure basic functionality, comfort and safety sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the sunshade cloth 24 of the present embodiment is:

[0051] S1: Put the flax fiber and nylon fiber into the sodium lauryl sulfate solution with a mass fraction of 10-20% and soak for 10-20min, the soaking temperature is 65-75°C, after soaking, wash with water, and then blend and blend the yarn Density is 2-3dtex, get the initial body of the fabric;

[0052] S2: Immerse the initial body of the fabric in the improver, and then adopt vacuum impregnation treatment, the impregnation pressure is 1-10Mpa, impregnate for 10-20min, after the impregnation is completed, then wash and dry to obtain the sunshade cloth 24;

[0053] In the preparation of the improver, the bentonite is sent into 2-3 times of hydrochloric acid, stirred and mixed until fully, and nano silicon dioxide with 10-20% of the total amount of bentonite is added to obtain the improver.

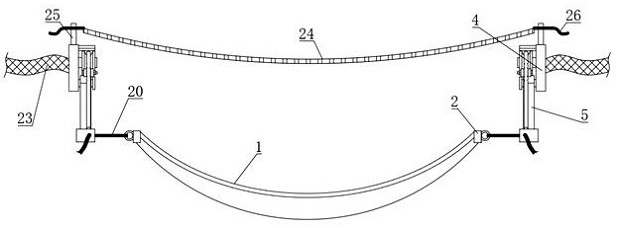

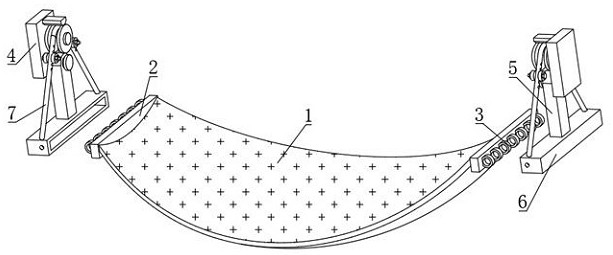

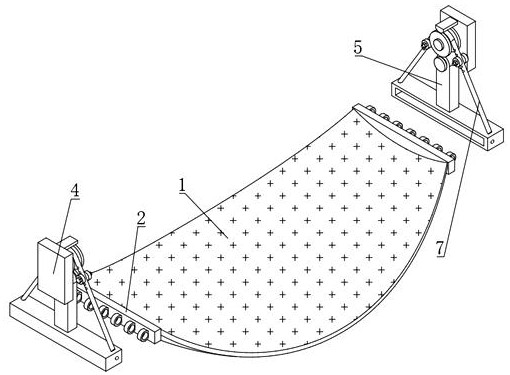

[0054] A preparation process for an anti-turnover hammock, comprising a hammock body 1, the left si...

Embodiment 1

[0075] The preparation method of the sunshade cloth 24 of the present embodiment is:

[0076] S1: Put flax fibers and nylon fibers into a 10% sodium lauryl sulfate solution and soak for 10 minutes at a temperature of 65°C. After soaking, wash with water, and then blend them with a linear density of 2dtex to obtain fabrics primary body;

[0077] S2: The initial body of the fabric is immersed in the improver, and then vacuum impregnated, the impregnated pressure is 1Mpa, impregnated for 10min, and the impregnated is completed, then washed and dried to obtain the sunshade cloth 24;

[0078] In the preparation of the improver, the bentonite is sent into 2-times hydrochloric acid, stirred and mixed until fully stirred, and 10% of the total amount of bentonite is added with nano-silicon dioxide to obtain the improver.

Embodiment 3

[0080] The preparation method of the sunshade cloth 24 of the present embodiment is:

[0081] S1: Put the flax fiber and nylon fiber into the sodium lauryl sulfate solution with a mass fraction of 20% and soak for 20 minutes at a temperature of 75°C. After soaking, wash with water, and then blend them with a linear density of 3dtex to obtain fabrics primary body;

[0082] S2: Immerse the fabric in the improver, and then adopt vacuum impregnation treatment, the impregnation pressure is 10Mpa, impregnate for 10-20min, after the impregnation is completed, then wash and dry to obtain the sunshade cloth 24;

[0083] In the preparation of the improver, the bentonite is sent into 3 times the amount of hydrochloric acid, stirred and mixed until fully stirred, and nano silicon dioxide with 20% of the total amount of bentonite is added to obtain the improver.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com