Design method of vacuum chuck

A technology of vacuum suction cup and design method, which is applied in the directions of packaging, conveyor objects, transportation and packaging, etc. It can solve the problems of material loss and grasping effect, less sheet materials, etc., and achieve good suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

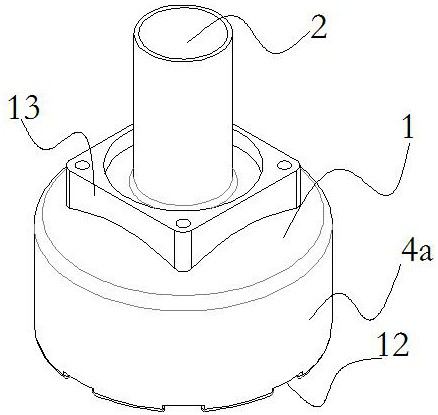

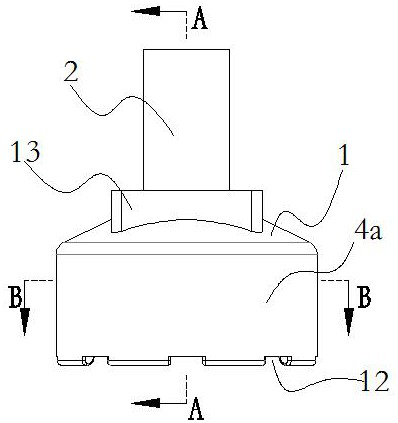

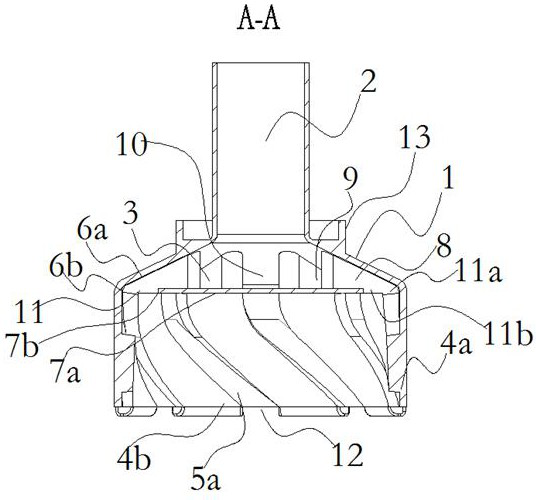

[0058] Refer to the attached figure 1 to attach Figure 7 , the present embodiment discloses a design method of a vacuum chuck, the designed vacuum chuck includes a chuck body 1, an air passage 2 and a vacuum chamber 3 communicating with each other are arranged in the suction cup body 1, and the vacuum chamber 3 is located below the air passage 2, The bottom of the suction cup body 1 is connected with a suction sleeve 4a, and the inner wall of the suction sleeve 4a is provided with a number of air suction grooves 5a;

[0059] The cavity shape of the vacuum chamber 3 is designed as an inverted funnel-shaped vacuum chamber 3, the opening end of the inverted funnel-shaped vacuum chamber 3 is connected with the suction sleeve 4a, and the closed end of the inverted funnel-shaped vacuum chamber 3 is connected with the air channel 2 The air channel 2, the vacuum chamber 3 and the suction sleeve 4a are coaxially arranged; the airtight partition 7a is arranged at the bottom of the vac...

Embodiment 2

[0065] As another preferred embodiment of the present invention, with reference to the attached figure 1 And attached figure 2As shown, this embodiment discloses a design method of a vacuum chuck. The designed vacuum chuck includes a chuck body 1, and an air passage 2 and a vacuum chamber 3 communicating with each other are arranged in the suction cup body 1. The vacuum chamber 3 is located in the air passage 2 Below, the suction sleeve 4a is connected to the bottom of the suction cup body 1, and a number of suction air grooves 5a are opened on the inner wall of the suction sleeve 4a;

[0066] The cavity shape of the vacuum chamber 3 is designed as an inverted funnel-shaped vacuum chamber 3, the opening end of the inverted funnel-shaped vacuum chamber 3 is connected with the suction sleeve 4a, and the closed end of the inverted funnel-shaped vacuum chamber 3 is connected with the air channel 2 The air channel 2, the vacuum chamber 3 and the suction sleeve 4a are coaxially ar...

Embodiment 3

[0085] In order to further highlight the difference between the effect of the vacuum suction cup designed by the design method of this application and the existing vacuum gripping device, the application made the following experiments:

[0086] Test conditions: (1) Vacuum pump fan is used as the negative pressure source, and the air extraction flow rate is 40m 3 / h;

[0087] (2) Picked and sorted objects: 90mm in diameter, 1.5mm in thickness, coarse grain cakes, sesame cakes or idyllic style cooking cakes, with a single cake weight of 10g;

[0088] (3) The vacuum suction cup is mounted on the delta three-axis manipulator.

[0089] Test sample one: use such as Figure 8 The structure of the vacuum chuck shown is that the vacuum chamber 3 is a cylindrical chamber, and a number of partition blocks 8 are arranged in the vacuum chamber 3, and vacuum air passages 9 are formed between the partition blocks 8, and the air suction groove 5a on the suction sleeve 4a adopts a parallel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com