Paper feeding mechanism of paper feeder and paper feeding method of paper feeding mechanism

A paper feeding mechanism and paper machine technology, which is applied to the paper feeding mechanism of the paper feeder, the paper feeding of the paper feeding mechanism of the paper feeder, and the field of the paper feeding mechanism, can solve the problem of increasing the downtime of the equipment, reducing the machine operation rate, double-sheet and Multiple sheets and other problems, to achieve reliable separation and stable transportation, avoid frequent shutdowns, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

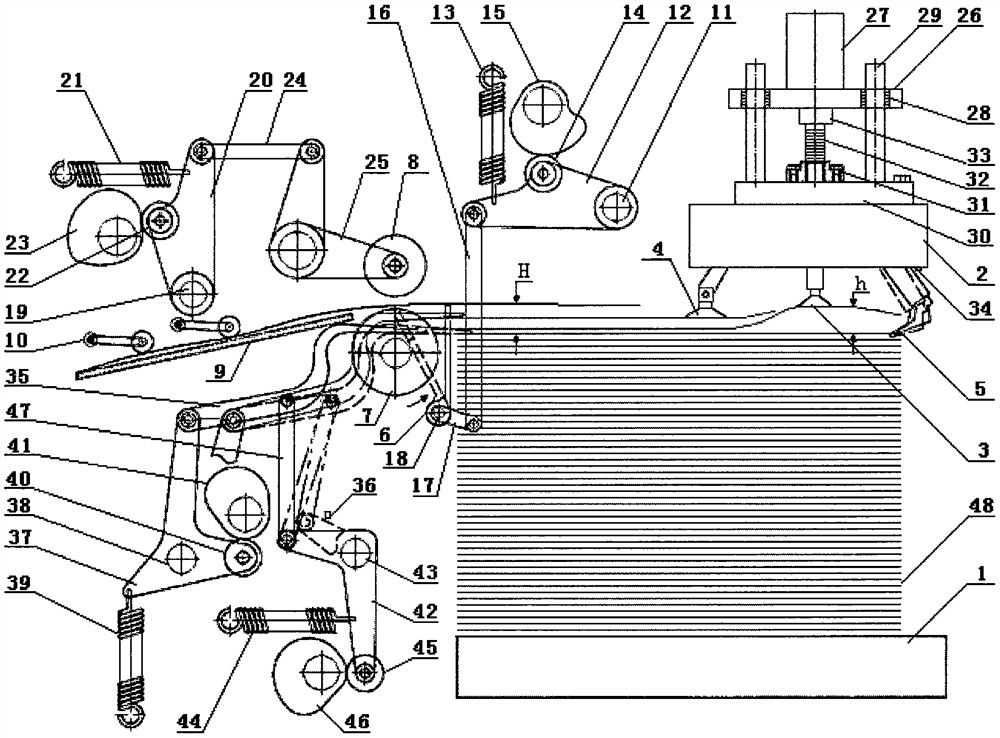

[0028] Describe in detail below by embodiment with reference to accompanying drawing:

[0029] A paper feeding mechanism for a paper machine, such as figure 1 As shown, it includes a paper feeding table 1, a paper separating device, a paper conveying device, a paper separating device height adjustment mechanism, and a paper stack height real-time detection and adjusting device. The paper feeding table 1 is arranged at the paper feeding station, and the paper separating device includes a The paper feeding head body 2 above the paper table 1, the paper separation nozzle 3, the paper delivery nozzle 4, and the paper stepping foot 5 arranged on the paper feeding head body 2, the paper separation nozzle 3 and the paper delivery nozzle 4 are respectively connected to the suction nozzle. The air pipeline, stepping on the paper foot 5 is also provided with a paper separation nozzle connected to the air blowing pipeline;

[0030] The paper conveying device comprises the paper feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com