Temporary protective coating demoulded by redox

A temporary protection and coating technology, applied in the field of coatings, can solve the problems of easy generation of copper chips and affect drilling accuracy, and achieve the effect of preventing copper chips and accelerating the time of automatic peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

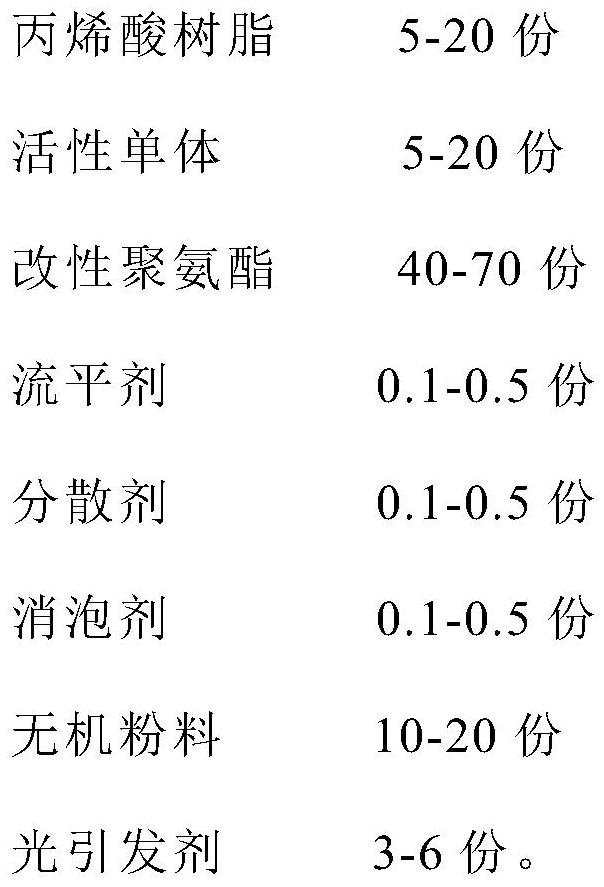

[0036] A temporary protective coating relying on oxidation-reduction release, in parts by weight, comprising the following components:

[0037]

Embodiment 2

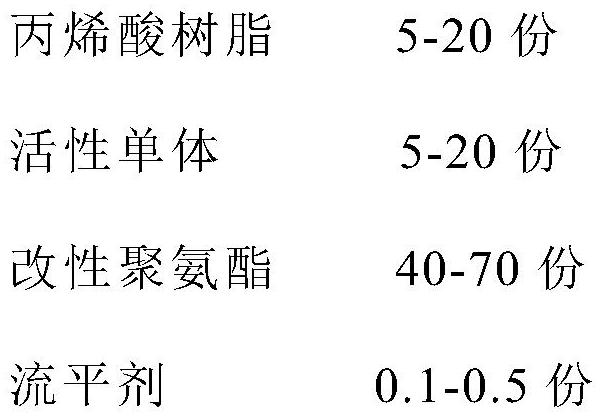

[0039] A temporary protective coating relying on oxidation-reduction release, in parts by weight, comprising the following components:

[0040]

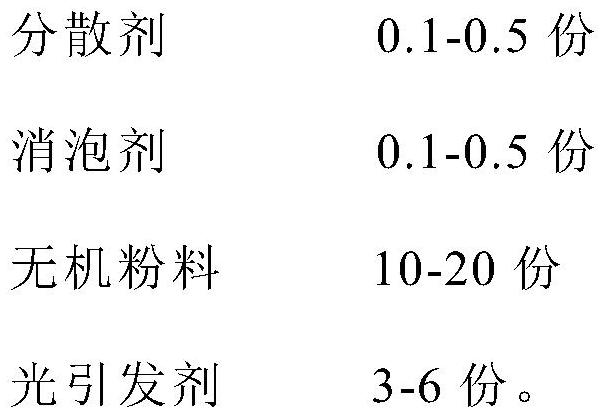

[0041]

Embodiment 3

[0043] A temporary protective coating relying on oxidation-reduction release, in parts by weight, comprising the following components:

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com