Graded pushing trolley system for bridge continuous pushing operation and construction method

A trolley system and jacking technology, used in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of slow jacking speed, short jacking distance, slow construction process, etc. The effect of pushing the card rail and avoiding deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

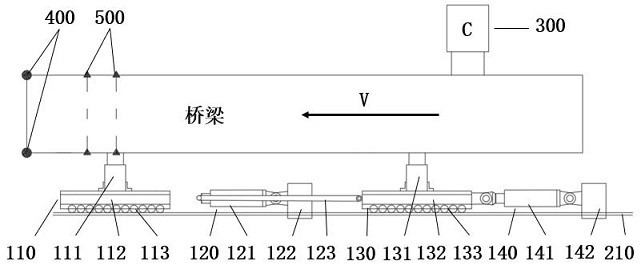

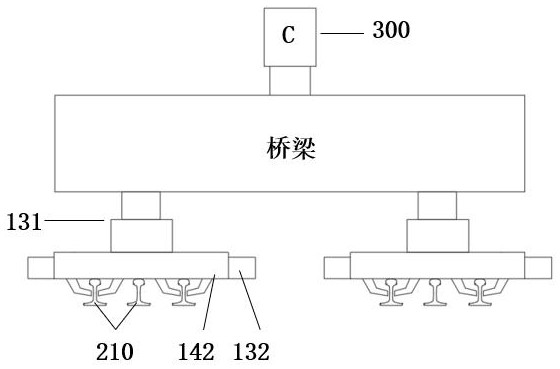

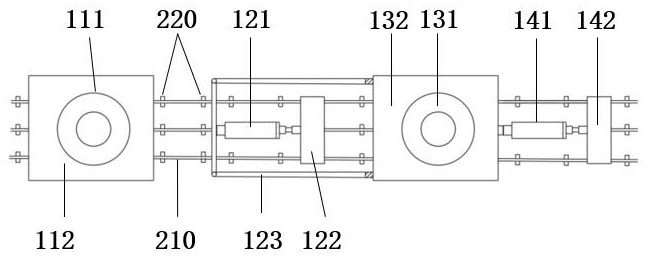

[0034] Such as Figure 1-4 As shown, the embodiment of the present invention provides a graded pushing trolley system and construction method for continuous bridge pushing operations, the system includes a hydraulic pushing and sliding device 100, a slideway 200, an automatic control system 300, and a positioning device 400 . Stress monitoring device 500; the hydraulic push-pull sliding device 100 includes a front heavy-duty sliding trolley 110, a front pushing device 120, a rear heavy-duty sliding trolley 130, and a rear pushing device 140. The device 120 cooperates with the rear pushing device 140 to realize continuous pushing; the slideway 200 includes three rows of rails 210 and crimping parts 220 arranged on the left and right sides along the pushing direction; the automatic control system 300 includes automatic Navigation control system 310, manual control system 320; the positioning device 400 is arranged at the centerline position of the upper and lower parts of the br...

Embodiment 2

[0045] In this embodiment, in view of the problems encountered in the pushing of curved bridges, step (4) in Embodiment 1 is adjusted, and the virtual curved track is preset in the automatic navigation control system 310. The automatic navigation control system 310 uses the positioning device 400 and The information collected by the stress monitoring device 500 judges whether the limit is exceeded. If the limit is exceeded, the pushing plan needs to be dynamically adjusted to regulate the pushing direction, such as Figure 6 Shown, all the other schemes are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com