Heat energy recycling system utilizing rubber wood carbon

A heat energy recovery and waste heat recovery technology, which is applied in the steam generation method using heat carrier, indirect heat exchanger, heat exchanger type, etc., can solve the problems of affecting the surrounding environment, environmental pollution, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

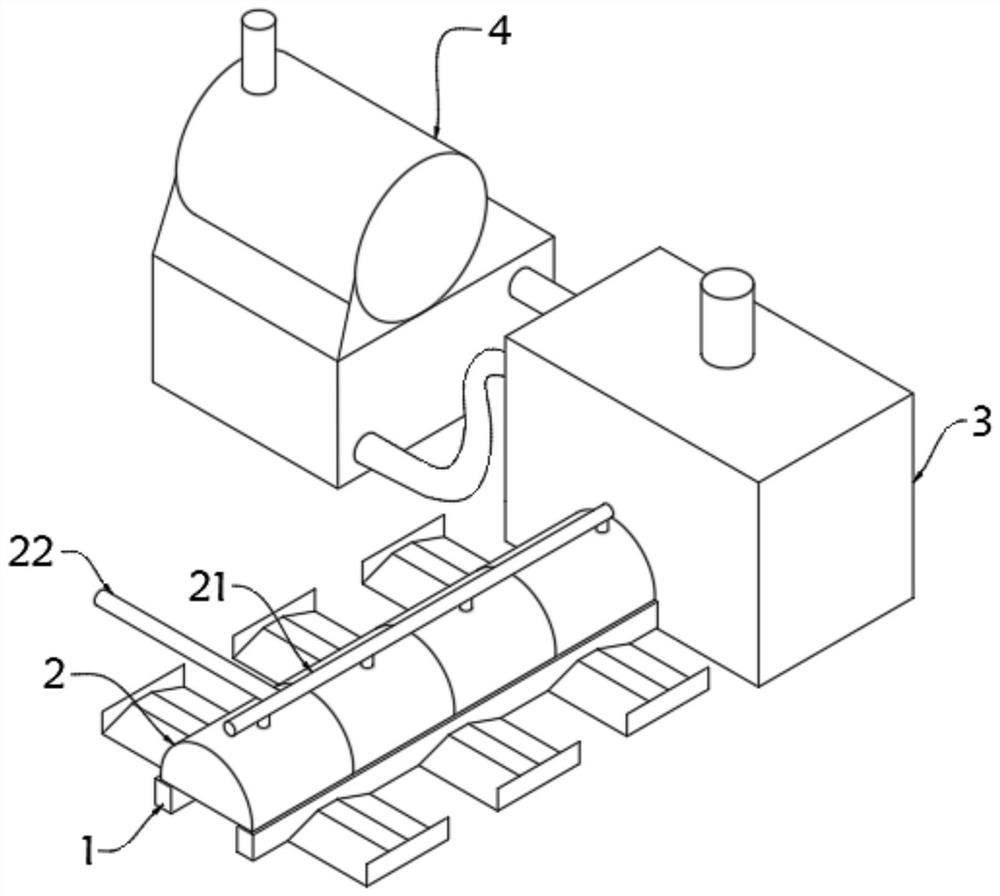

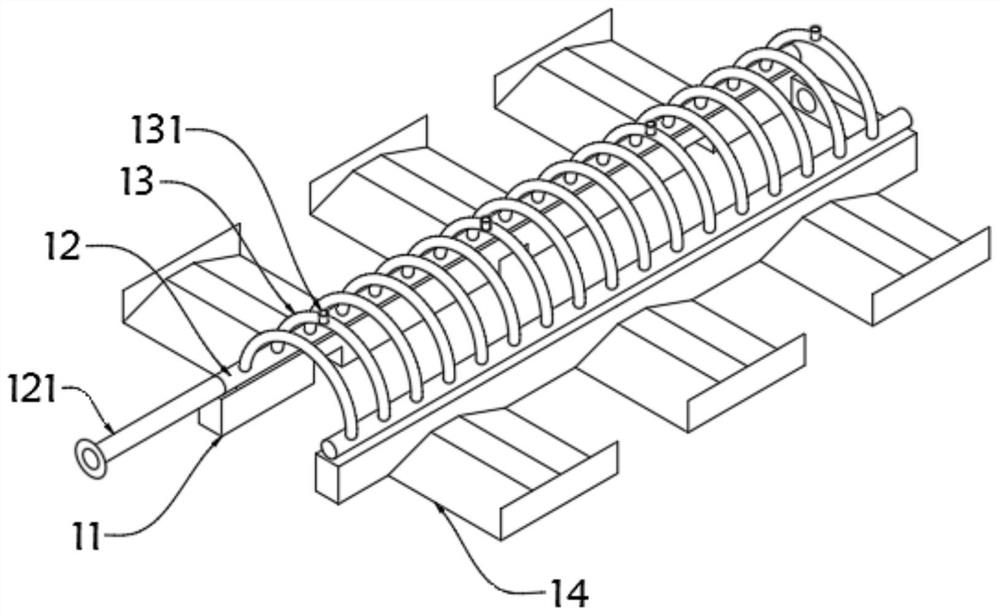

[0027] The invention provides a heat recovery and utilization system utilizing rubber wood carbon, such as Figure 1-Figure 2 As shown, it includes a waste heat recovery mechanism 1, which is used to process and recover the waste heat generated in the carbon production process. One end of the waste heat recovery mechanism 1 is connected to a combustion furnace 3, which is used to fully burn the waste heat and remove harmful gases such as carbon monoxide inside. One end of the combustion furnace 3 is connected with a fluidized fluidized furnace 4 for further recycling the waste heat generated in the combustion furnace 3. A sealing cover 2 is installed on the top of the waste heat recovery mechanism 1 to seal the top of the waste heat recovery mechanism 1 to avoid To dissipate the heat, a steam recovery pipeline 21 is installed on the top of the sealing cover plate 2 for recovering the steam generated by the waste heat recovery mechanism 1 for convenient transmission and utilizat...

Embodiment 2

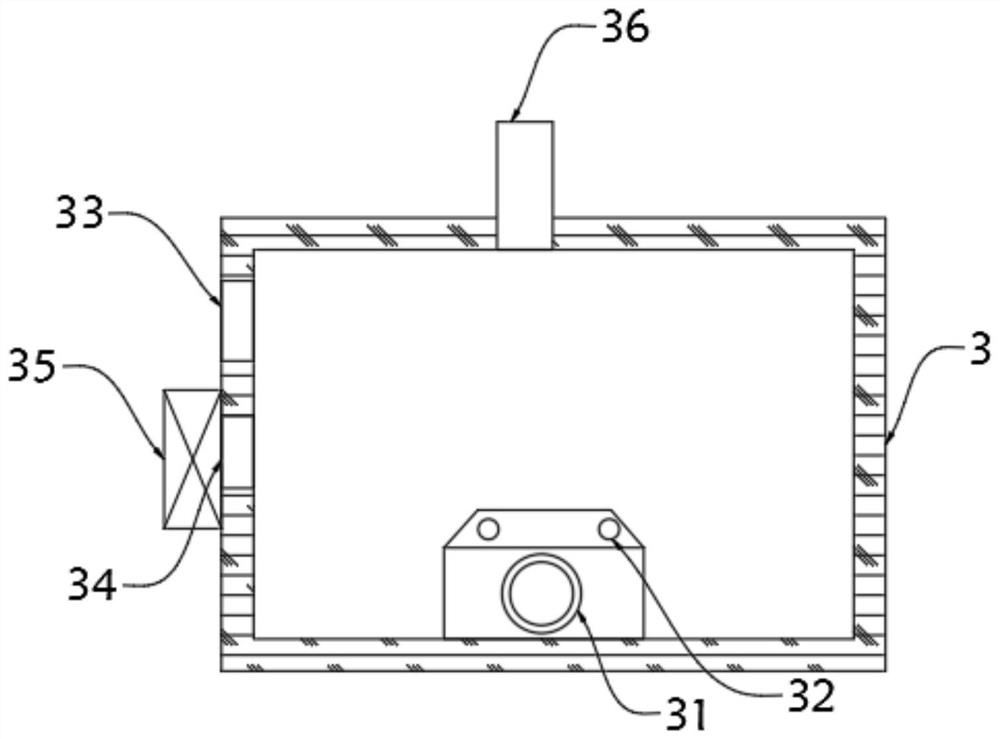

[0033] In order to further improve the utilization efficiency of waste heat in the combustion furnace 3, as Figure 3-4 As shown, an outer wall of one side of the combustion furnace 3 is provided with an air inlet 31, and an igniter 32 is installed near the air inlet 31 on the inner wall of the combustion furnace 3, for igniting the waste heat that is passed in to make it fully combustible, and the combustion furnace 3 The upper part of one side of the outer wall is provided with a hot gas outlet 33, and the lower part of one side of the outer wall of the combustion furnace 3 is provided with a circulation inlet 34, which recycles the gas passed into the fluidized fluidized furnace 4 after use, so that the remaining heat can be continuously used to avoid energy loss.

[0034] Further, a waste heat circulation pipe 41 is installed inside the fluidized fluidized furnace 4 , a waste heat inlet pipe 42 is arranged on the upper part of the outer wall of the fluidized fluidized furna...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap