Device and method for detecting compaction degree of on-site filling roadbed based on shear wave velocity

A detection device and shear wave technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, analyze materials, instruments, etc. It can solve the problems of large disturbance, insufficient reliability, and difficulty in taking out complete core samples, so as to ensure accuracy performance and reliability, and the effect of reducing crowding disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

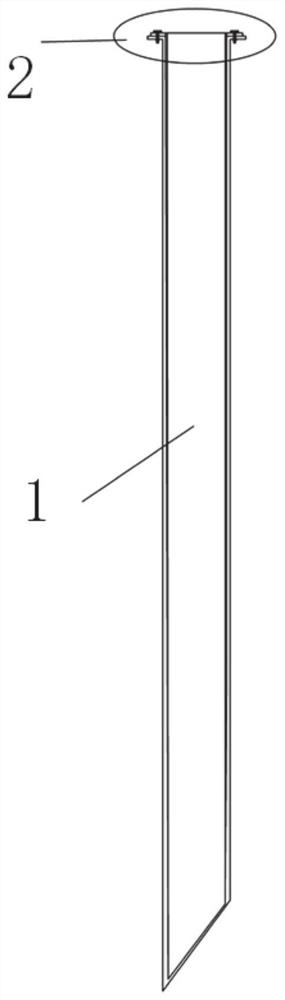

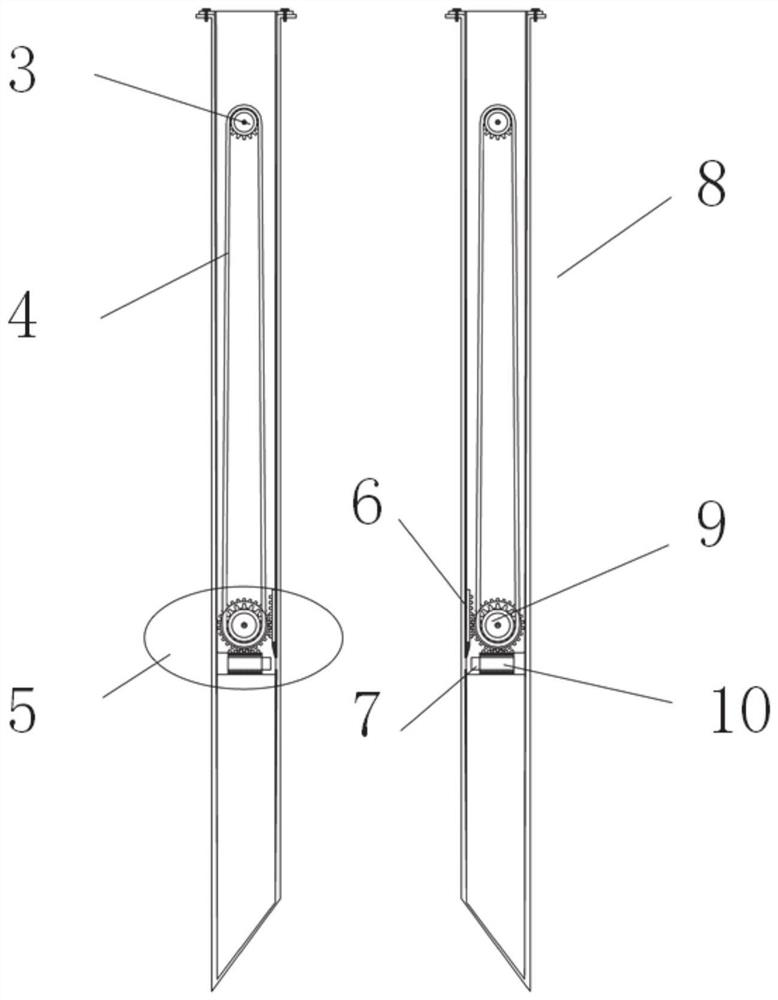

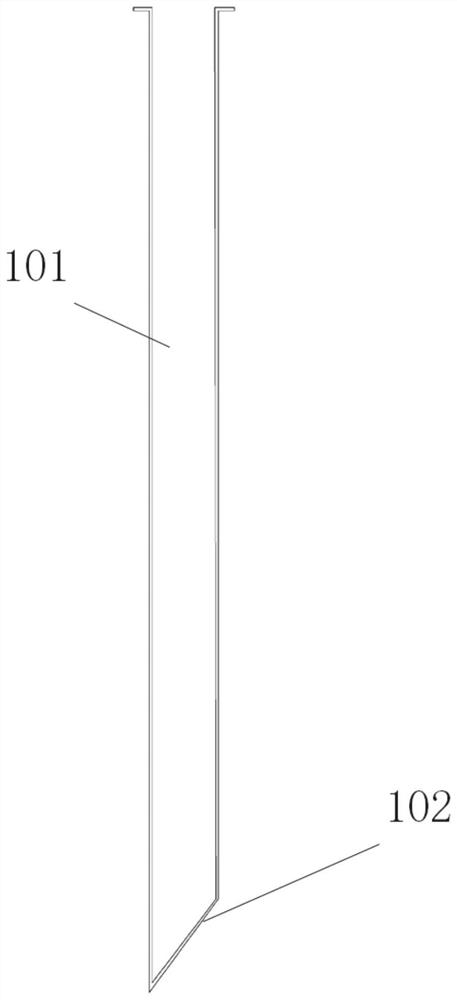

[0056] In a typical embodiment of the present invention, refer to figure 2 As shown, the on-site filling subgrade compaction detection device based on shear wave velocity includes a shear wave excitation mechanism and a shear wave receiving mechanism 8, which can be inserted into the filling subgrade at a set distance, and the shear wave excitation mechanism and the shear wave receiving mechanism both include an outer casing 101 , an inner core tube 103 for taking soil, and an inner core rod 11 of a bending element.

[0057] an outer casing with a hollow interior, and a first opening is provided on the side wall;

[0058] Soil-taking core pipe, both inside and bottom are hollow, refer to Figure 4 shown, and can be detachably connected with the outer casing, so that when the outer casing is inserted into the soil, the soil inside the outer casing enters the soil-absorbing inner core pipe, and the soil-absorbing inner core pipe can be moved relative to the outer casing under ...

Embodiment 2

[0091] The difference between this embodiment and Embodiment 1 is:

[0092] The moving mechanism is a first linear drive mechanism, the first linear drive mechanism is fixed in the rod body, and the first linear drive mechanism is connected with the bending element test piece to drive the bending element test piece to move;

[0093] A movable opening and closing door is arranged in the rod body at the second opening, and the opening and closing door is connected with the second linear drive mechanism to drive the opening and closing door to close or open the second opening.

[0094] Specifically, both the first linear drive mechanism and the second linear drive mechanism can be drive motors, the first motor drives the linear movement of the bending element test piece, and the first motor drives the bending element test piece to reciprocate through the rack and pinion mechanism. linear motion;

[0095] The second motor is fixed above the second opening of the rod body, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com