A collagen peptide drying system

A collagen peptide and drying system technology, applied in the drying field, can solve the problems of reducing the cleaning degree of the inner wall of the drying barrel and affecting the processing of collagen powder, and achieve the effect of increasing the cleaning degree and increasing the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

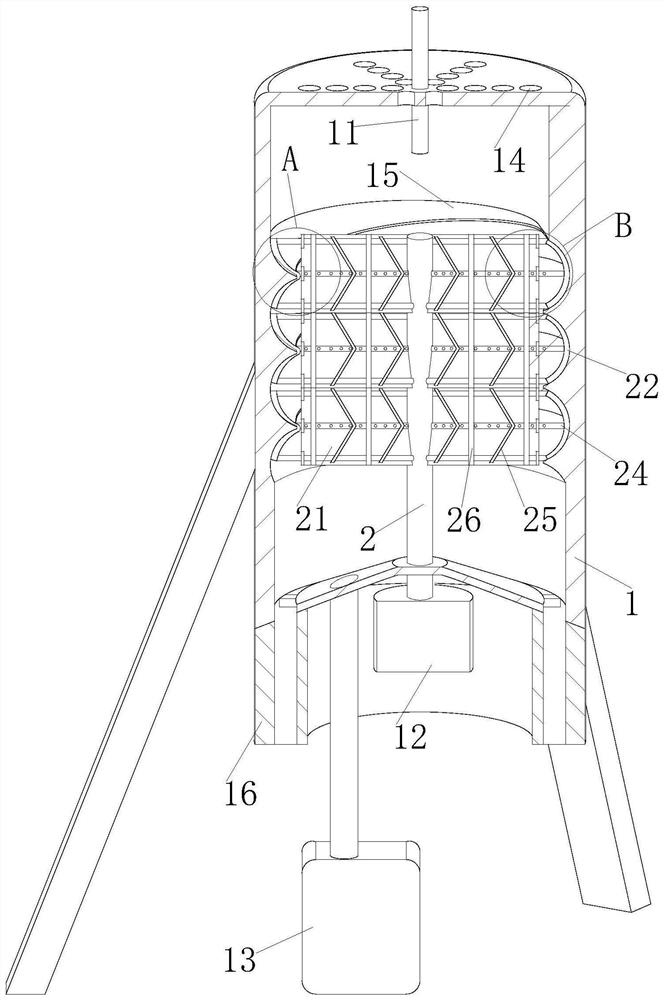

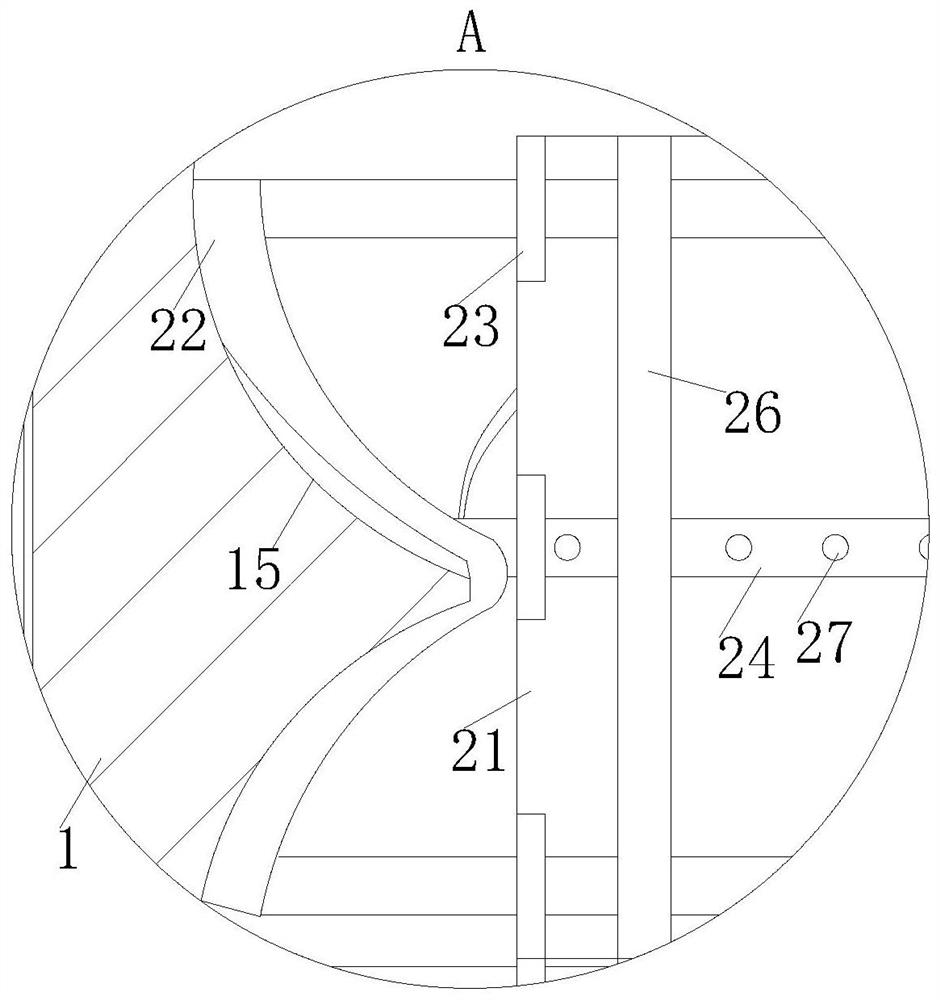

[0031] As an embodiment of the present invention, the cross section of the scraper strip 22 is composed of a straight line a and a circular arc b, and one end of the straight line a away from the circular arc b is in contact with the inner wall of the housing 1 .

[0032] When in use, by setting the scraper 22, the scraper 21 drives the slide bar 24 to move, the slide bar 24 drives the scraper 22 to move, and the straight line a part of the scraper 22 contacts the collagen peptide powder solidified in the spiral groove 15, and the scraper 22 The middle line a part removes the collagen peptide powder from the spiral groove 15, which increases the cleaning effect of the scraper 22, thereby increasing the cleaning degree in the spiral groove 15, preventing the remaining collagen peptide powder in the spiral groove 15, resulting in collagen The drying efficiency of protein peptide decreases; after the scraper 22 scrapes off the collagen peptide powder, part of the collagen peptide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com