Synchronous material supporting structure of sheet metal forming automatic production line

An automatic production line and sheet metal technology, applied in the direction of conveyors, packaging, mechanical conveyors, etc., can solve the problems of small adjustment range and cumbersome control, etc., and achieve the effect of simple control and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

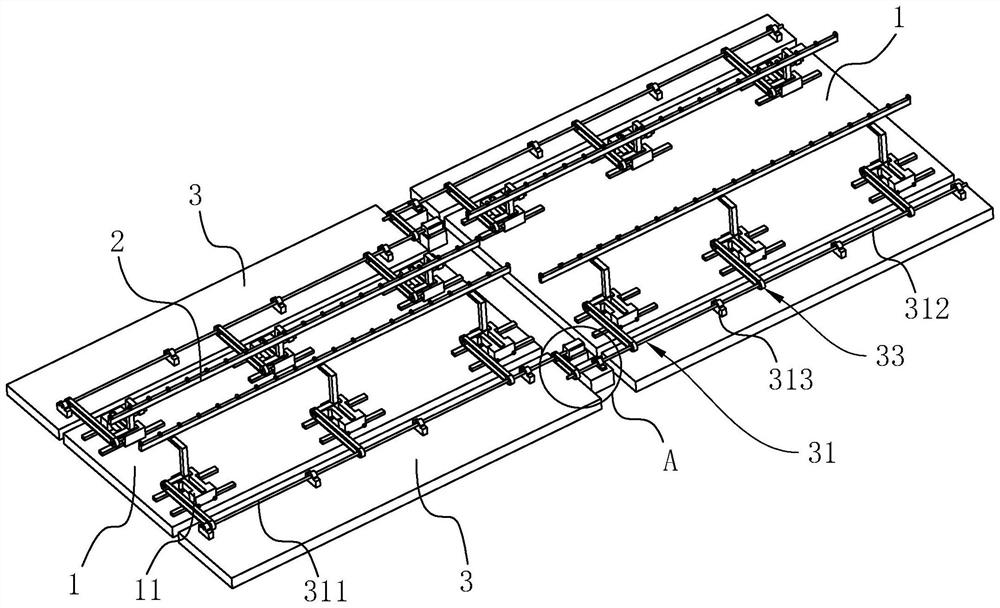

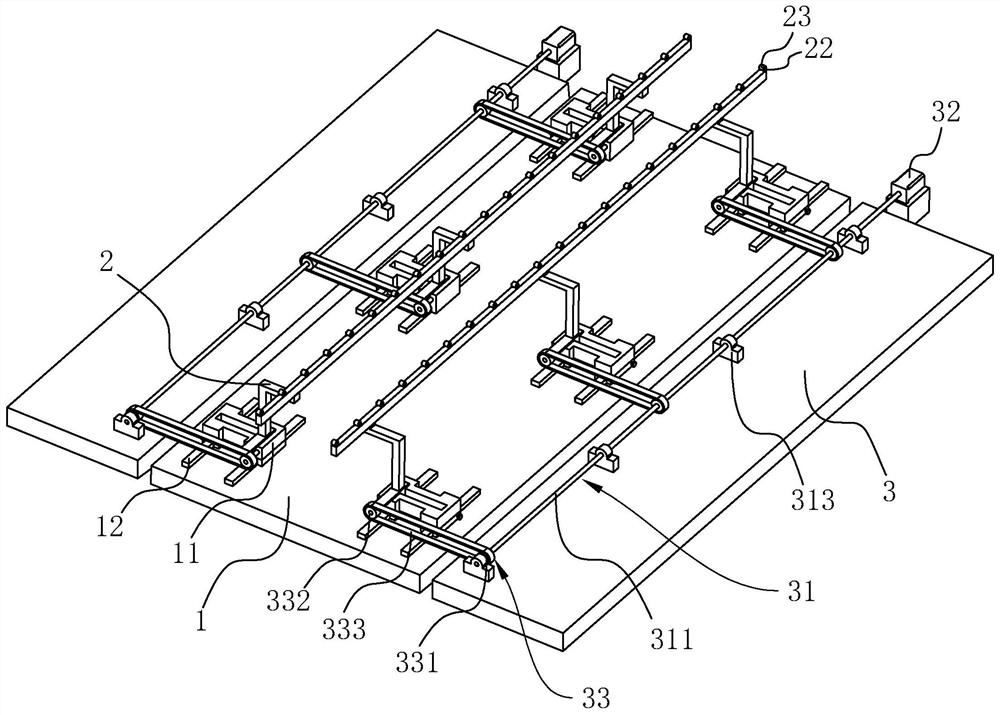

[0039] Embodiment 1. The present invention provides a synchronous support structure for an automatic sheet metal forming production line, such as figure 1 and figure 2 As shown, it includes a main frame body 1 and a plurality of sliding brackets 2 slidingly connected to the main frame body 1. The sliding brackets 2 slide along a direction perpendicular to the length of the sliding brackets 2. The length directions of all sliding brackets 2 are mutually Parallel, the sliding brackets 2 are divided into two groups and the two groups of sliding brackets 2 are all connected end to end along their own length direction.

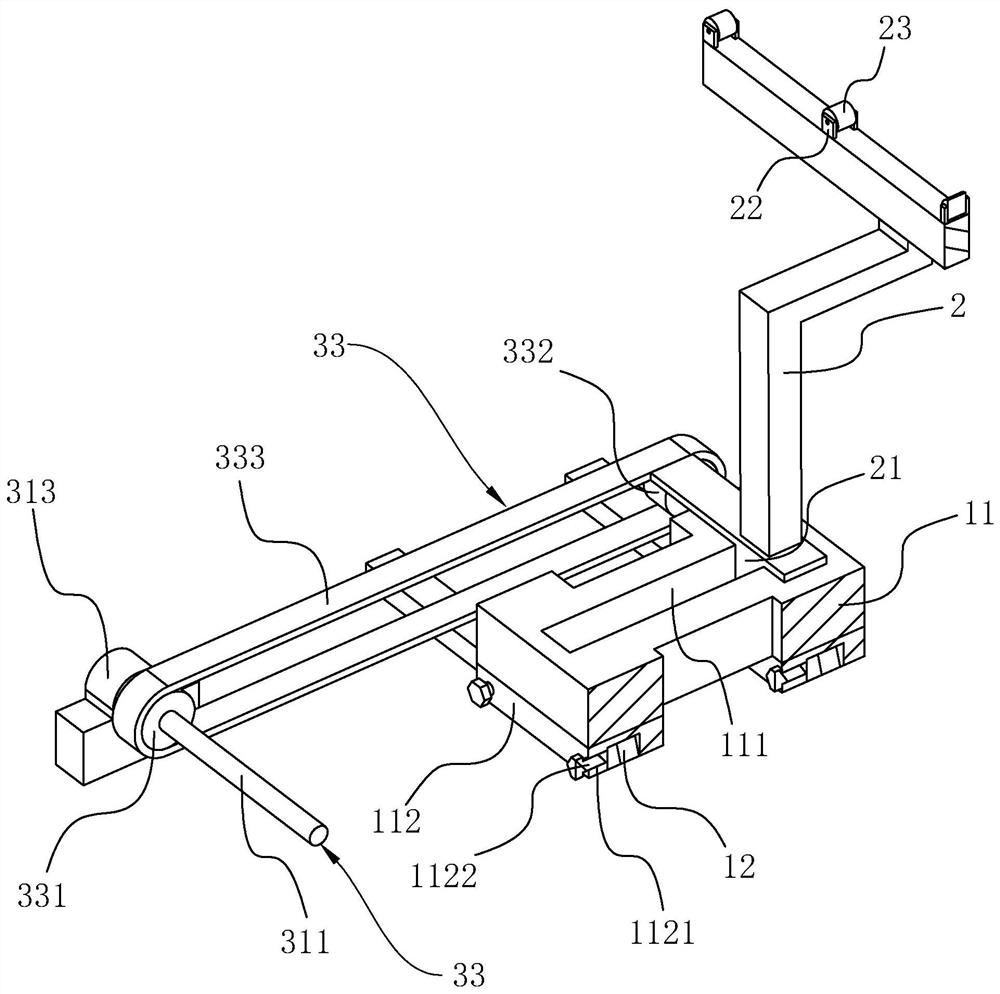

[0040] Such as figure 2 and image 3 As shown, the top of the sliding bracket 2 is fixedly connected with a plurality of roller seats 22, and each roller seat 22 is rotatably connected with a supporting roller 23, and the supporting rollers 23 are arranged along a direction perpendicular to the length of the sliding bracket 2. . The support roller 23 changes ...

Embodiment 2

[0047] Embodiment 2. The present invention provides a synchronous support structure for an automatic sheet metal forming production line, such as Figure 5 As shown, the difference from Embodiment 1 is that the synchronization assembly 33 includes a first gear 334 fixedly connected to the rotating shaft 31, the sliding bracket 2 is rotatably connected with a second gear 335, the first gear 334 and the second gear 335 A synchronous rack 336 is sleeved together, and the sliding bracket 2 is fixedly connected to the synchronous rack 336 . Rotation of the rotating shaft 31 drives the first gear 334 to rotate, the first gear 334 drives the second gear 335 to rotate through the synchronous rack 336, and the rotation of the synchronous rack 336 can drive the sliding bracket 2 to move.

[0048] The main frame body 1 is fixedly connected with a slide rail 13 perpendicular to the length direction of the slide bracket 2 at the position corresponding to each slide bracket 2, and each slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com