Preparation technology of black fermented glutinous rice

A preparation process, a technology of fermented glutinous rice, which is applied in the field of black fermented glutinous rice preparation, can solve the problems of being unable to store at room temperature and harsh storage environment, and achieve the effect of suitable alcohol content, unique color and pure smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

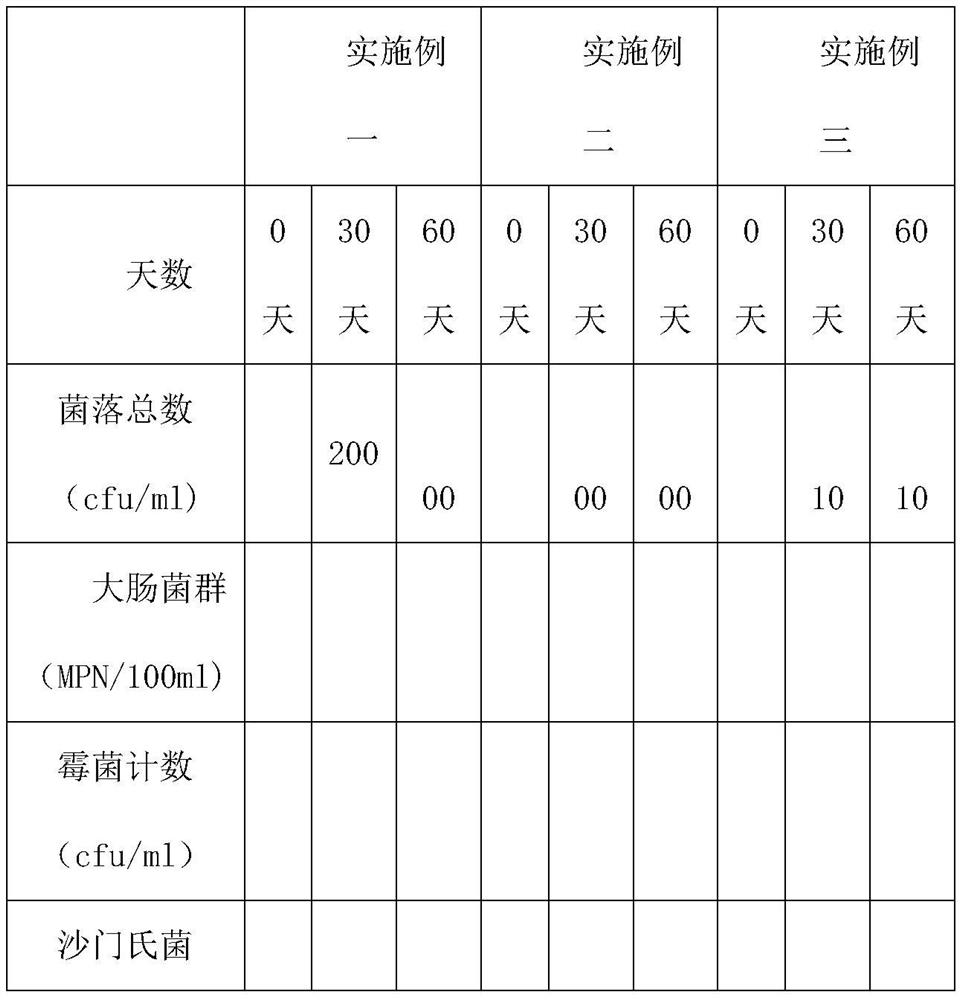

Examples

Embodiment 1

[0029] A preparation process for black fermented glutinous rice, comprising the following steps:

[0030] Step 1: Wash, put the raw glutinous rice in a jar, add water to submerge the raw glutinous rice and make it 10 cm higher, stir and knead the raw glutinous rice with a stirring rod for 5 minutes, and wash it repeatedly 3 times;

[0031] Step 2: Soak, add cold water to the cleaned raw glutinous rice to make it submerged to a height of 15 cm, soak for 5 hours;

[0032] Step 3: steaming, put the soaked raw glutinous rice in a steamer, and when the temperature of steam at atmospheric pressure is 110°C, the steaming time is 50 minutes;

[0033] Step 4: cooling down, using 100° C. pure water of 10% of the mass of the cooked raw material glutinous rice to cool down the raw material glutinous rice;

[0034] Step 5: Spread to cool, spread out the raw glutinous rice and let it cool naturally to room temperature 18°C;

[0035] Step 6: Mix the koji, then sprinkle the yeast evenly acc...

Embodiment 2

[0043] A preparation process for black fermented glutinous rice, comprising the following steps:

[0044] Step 1: Wash, put the raw glutinous rice in a jar, add water to submerge the raw glutinous rice and make it 15 cm higher, stir and knead the raw glutinous rice with a stirring rod for 10 minutes, and wash it 3 times;

[0045] Step 2: Soak, add cold water to the cleaned raw rice so that it is submerged to a height of 20 cm, soak for 6 hours;

[0046] Step 3: steaming, put the soaked raw glutinous rice in a steamer, and when the temperature of steam at atmospheric pressure is 120°C, the steaming time is 45 minutes;

[0047] Step 4: cooling down, using 100° C. pure water of 10% of the mass of the cooked raw material glutinous rice to cool down the raw material glutinous rice;

[0048] Step 5: Spread to cool, spread out the raw glutinous rice and let it cool naturally to room temperature 20°C;

[0049] Step 6: Mix the koji, then sprinkle the yeast evenly according to the mas...

Embodiment 3

[0057] A preparation process for black fermented glutinous rice, comprising the following steps:

[0058] Step 1: Washing, put the raw glutinous rice in a tank, add water to submerge the raw glutinous rice and make it 20 cm higher, stir and knead the raw glutinous rice with a stirring rod for 15 minutes, and wash it repeatedly 3 times;

[0059] Step 2: Soak, add cold water to the cleaned raw glutinous rice to make it submerge the glutinous rice to a height of 25 cm, soak for 7 hours;

[0060] Step 3: steaming, put the soaked raw glutinous rice in a steamer, and when the temperature of steam at atmospheric pressure is 130°C, the steaming time is 40 minutes;

[0061] Step 4: cooling down, using 100° C. pure water of 10% of the mass of the cooked raw material glutinous rice to cool down the raw material glutinous rice;

[0062] Step 5: Spread to cool, spread out the raw glutinous rice and let it cool naturally to room temperature 22°C;

[0063]Step 6: Mix the koji, then sprinkl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com