Steel beam connecting structure of steel structure factory building

A technology for connecting structures and steel structures, which is applied to building structures, building types, buildings, etc. It can solve the problems of low rigidity of light steel beams, loose bolts at the joints, brittle welds at the joints, etc., and achieves convenient and fast welding , Guaranteed safety and stable connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

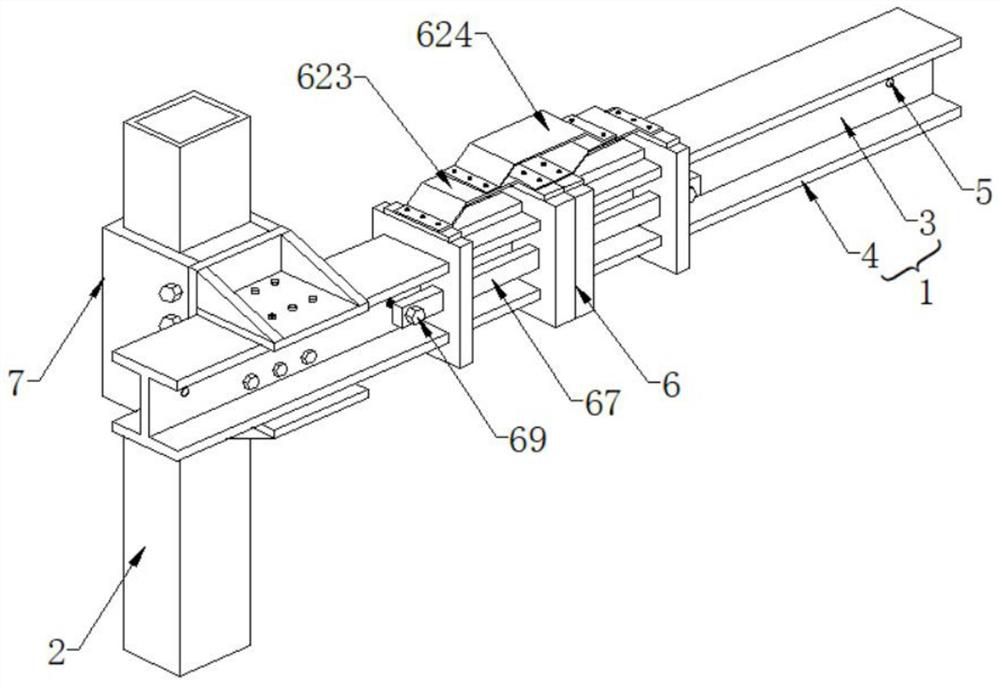

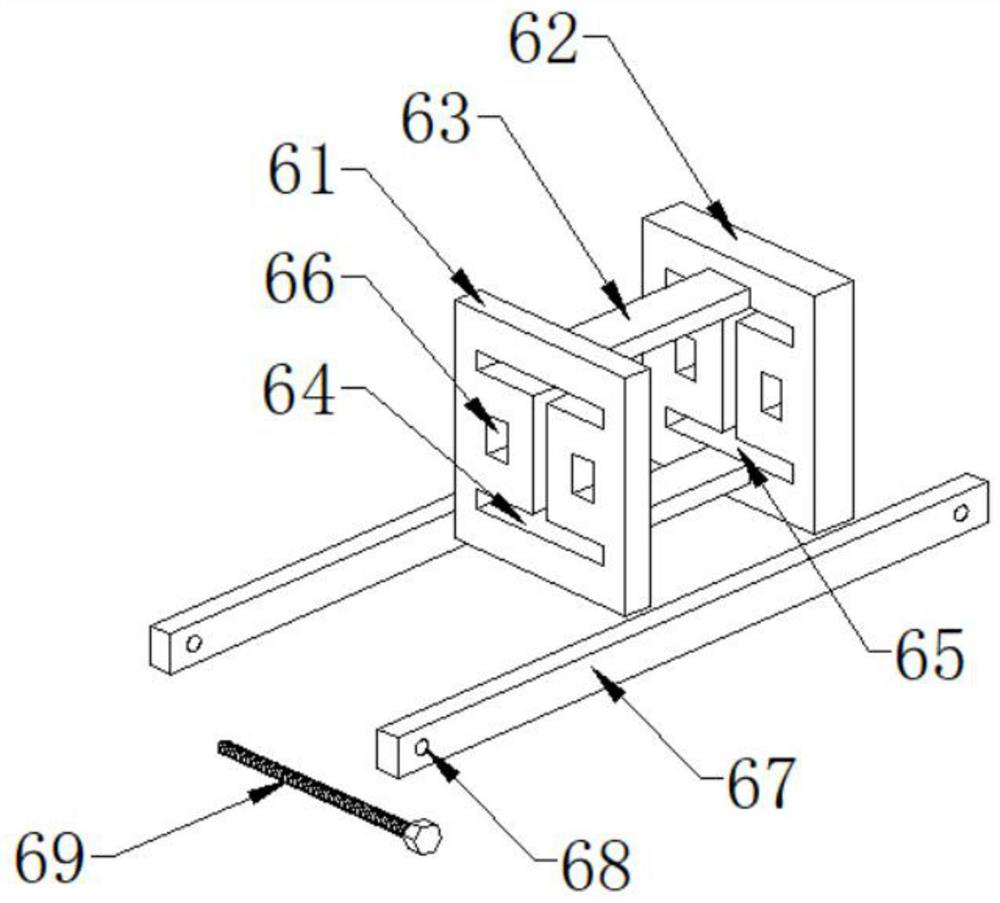

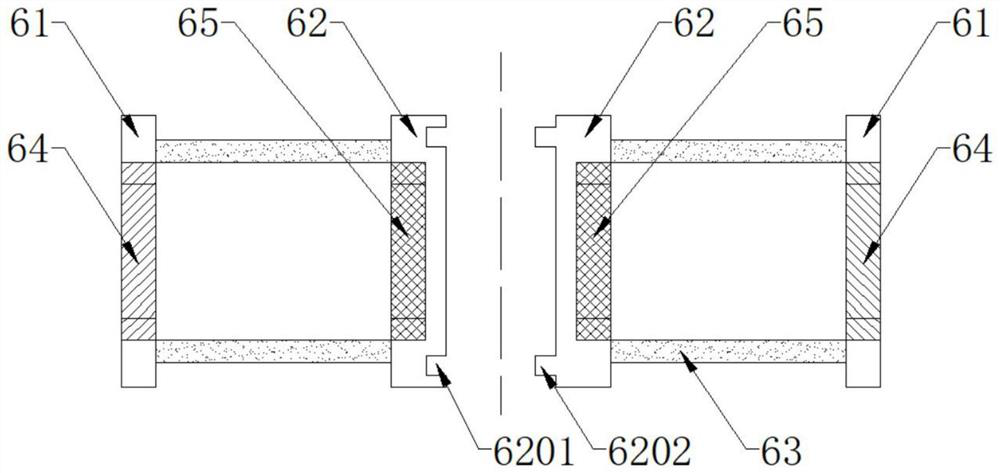

[0026] Such as Figure 1-6 As shown, the present invention provides a steel structure factory building steel beam connection structure, including a horizontal steel beam 1 and a supporting vertical steel 2, the horizontal steel beam 1 is connected in the same direction, one side of the supporting vertical steel 2 is connected to the horizontal steel beam 2, and the horizontal steel beam 2 is connected The steel beam 1 includes a web 3 and a wing 4. The upper and lower ends of the web 3 are connected with the wing 4 to form an I-shaped structure. Both ends of the web 3 are provided with first screw holes 5, and the adjacent transverse The two ends of the steel beam 1 are connected by the first connecting device 6, the first connecting device 6 is composed of two connecting units arranged in mirror image, the connecting unit includes the first set plate 61, the second set plate 62 and the connecting strut 63, the first set plate 61 and the second set plate 62 are arranged side b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com