Bidirectional metering table for power transmission line

A technology of transmission lines and metering stations, which is applied in the direction of measuring electrical variables, measuring devices, electrical components, etc., can solve problems such as poor flame retardancy, and achieve the effects of improving safety performance, improving cooling ability, and improving fire extinguishing and flame retardancy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

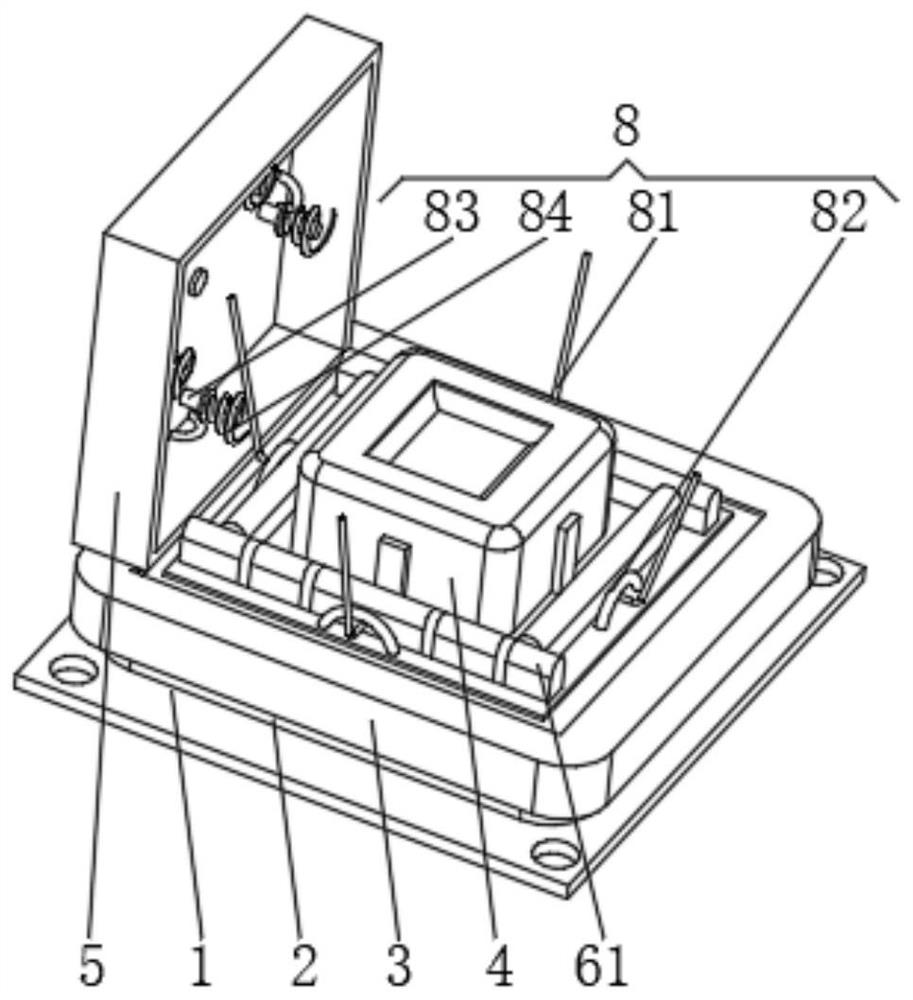

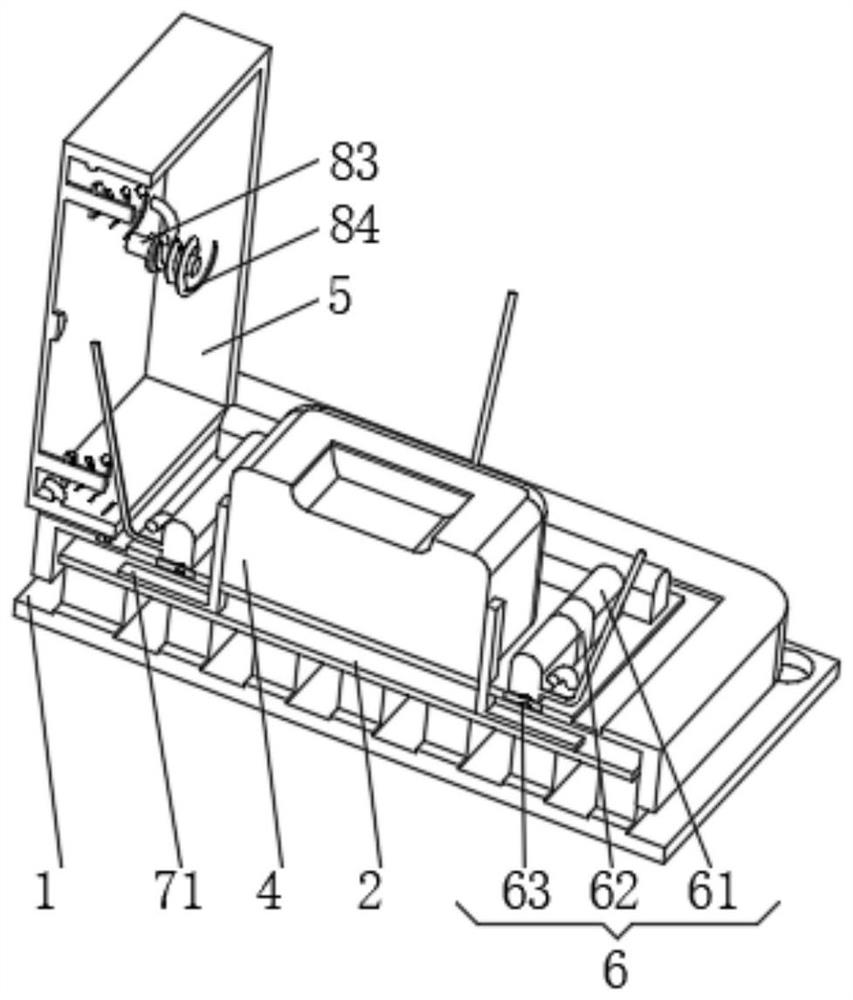

[0031] see Figure 1-2 , the present invention provides a technical solution: a two-way metering platform for power transmission lines, including a mounting plate 1, one side of the mounting plate 1 is evenly opened with mounting holes, one side of the mounting plate 1 is fixedly connected with a cooling frame 2, the cooling frame The outside of 2 is covered with an installation frame 3, the side of the installation frame 3 away from the heat dissipation frame 2 is fixedly connected to the main body 4 of the metering table, and the side of the installation frame 3 is rotatably connected to the sealing box 5, and the outside of the installation frame 3 is provided with:

[0032] Flame retardant device 6, the flame retardant device 6 has a flame retardant bag 61, the inside of the flame retardant bag 61 is filled with dry powder fire extinguishing agent, the outside of the flame retardant bag 61 is provided with a limit bar 62, the limit bar 62 is made of plastic film material, ...

Embodiment 2

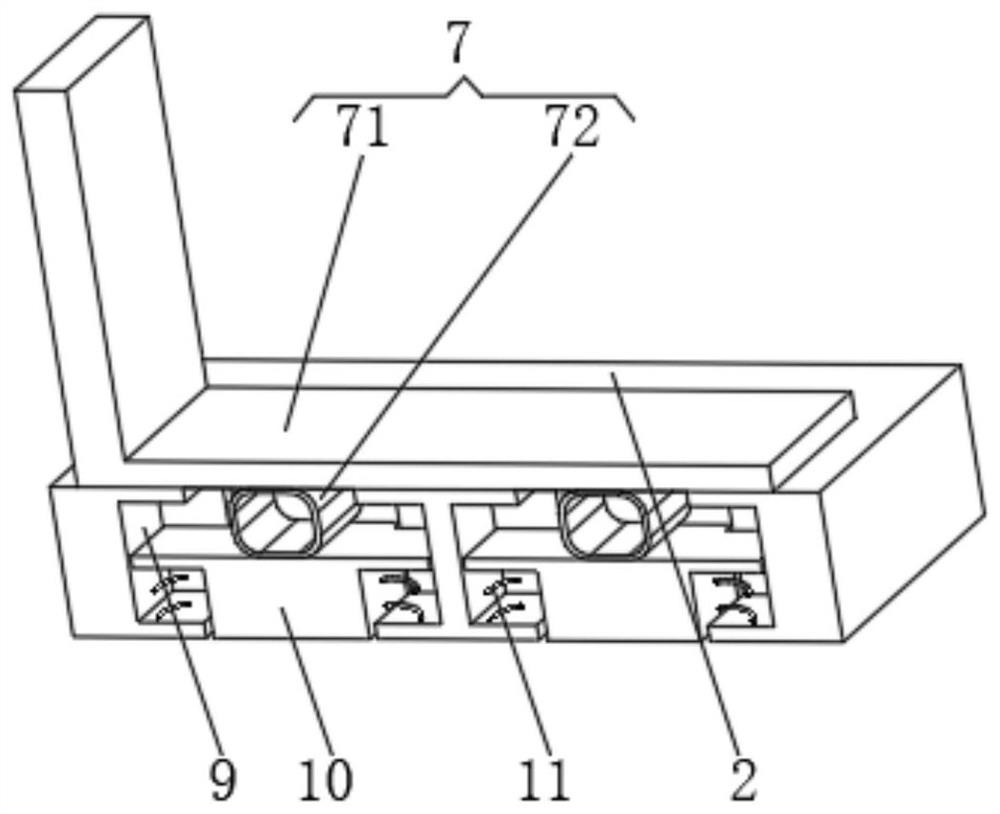

[0036] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, an opening and closing device 7 is provided outside the installation frame 3, and the opening and closing device 7 has a heat conduction sheet 71, and the heat conduction sheet 71 is fixedly connected with the main body 4 of the metering platform, The heat conduction sheet 71 runs through the installation frame 3 and extends to the top of the heat dissipation frame 2 , and an air bag 72 is fixedly connected under the heat conduction sheet 71 .

[0037] The top of the heat dissipation frame 2 is provided with a functional groove 9 that is compatible with the inflatable bag 72. The functional groove 9 runs through the heat dissipation frame 2. A pressure platform 10 is slidably connected between the two sides of the inner wall of the functional groove 9. The bottom of the pressure platform 10 A pressure-bearing spring 11 is installed symmetrically, and one end of the press...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap