Drawing tool box for architectural design

A technology for drawing tools and architectural design, applied in the field of toolboxes, which can solve the problems of a single toolbox structure, inability to protect tools, and the inability of toolboxes to provide drawing planes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

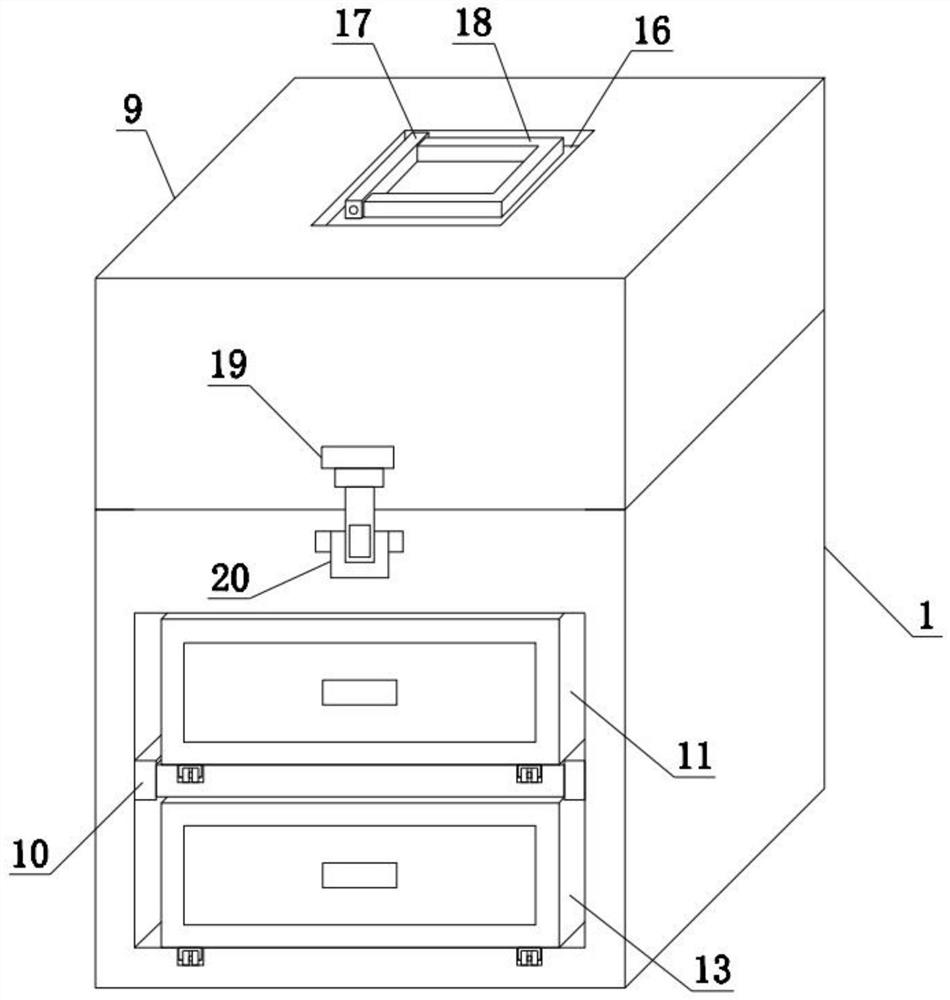

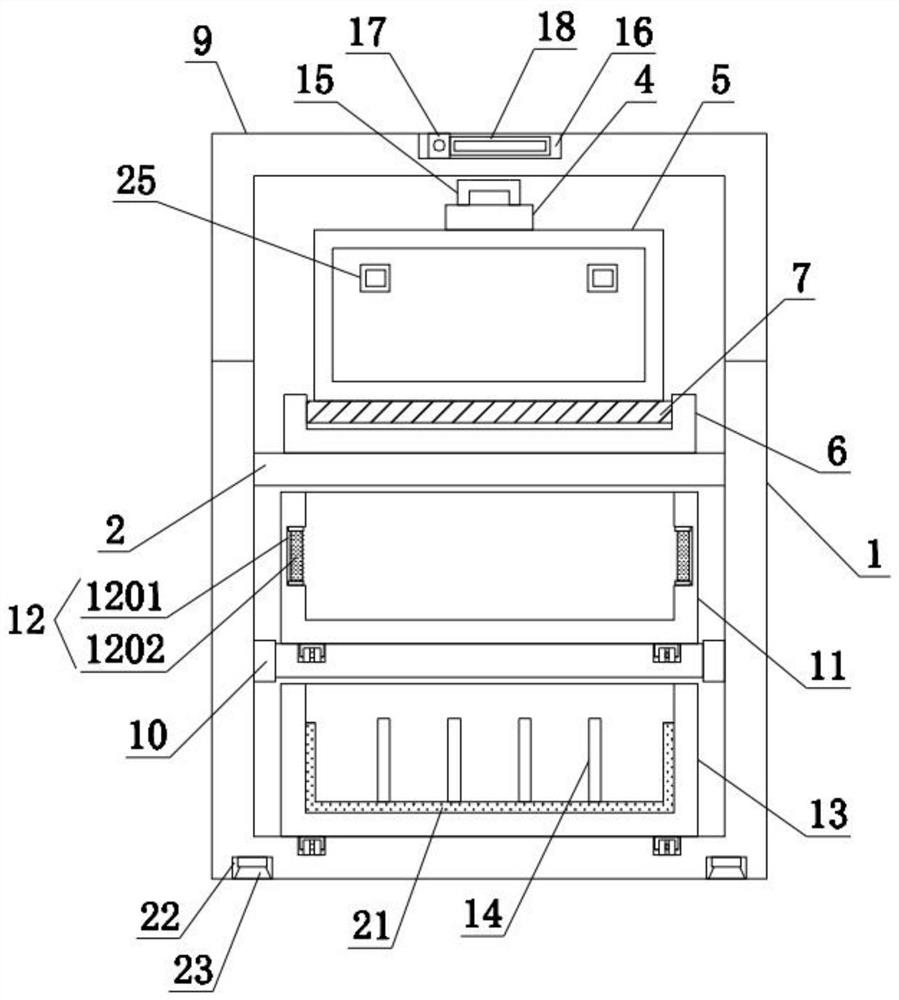

[0034] refer to Figure 1-4 , a drawing toolbox for architectural design described in this embodiment, comprising a box body 1, the inner upper end of the box body 1 is fixedly connected with a first partition 2, and the top rear end of the first partition 2 is fixedly equipped with a telescopic mechanism 3. The top of the telescopic mechanism 3 is fixedly connected with the connection base 4, the front lower end of the connection base 4 is fixedly connected with the support plate 5, the top front end of the first partition 2 is fixedly connected with the mounting base 6, and the inside of the mounting base 6 is fixedly installed with Rotating shaft 7, the other end of support plate 5 is connected with rotating shaft 7, and the back upper end of casing 1 is hinged with case cover 9 by hinge 8, and the inner middle end of casing 1 is fixedly connected with second dividing plate 10, and the second dividing plate The top of the board 10 is slidably connected with the first drawer...

Embodiment 2

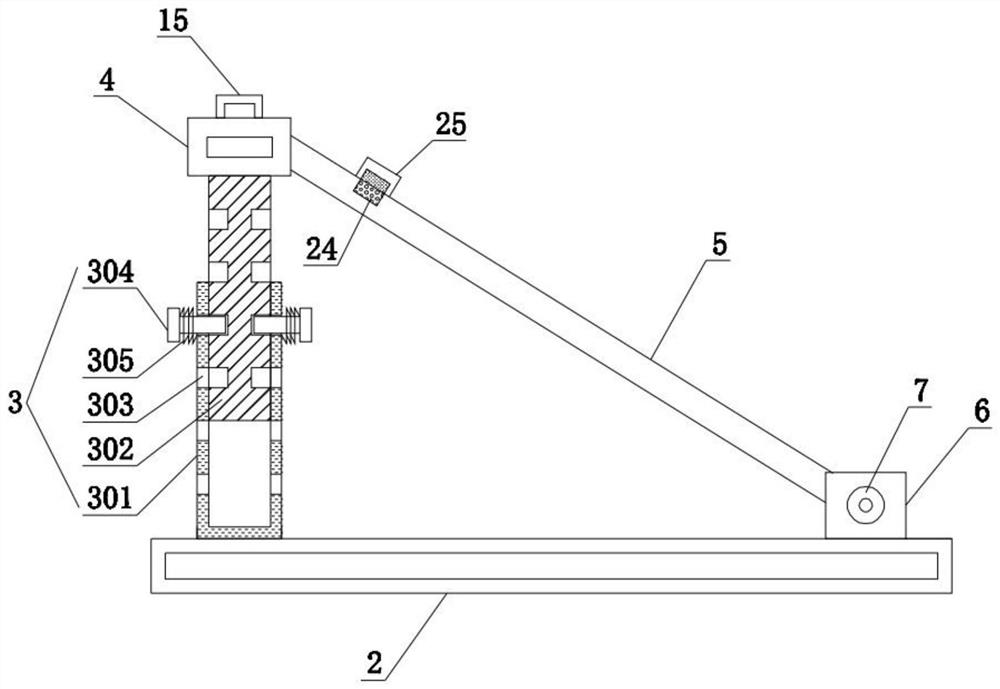

[0037] refer to image 3 , on the basis of Embodiment 1, in order to achieve the purpose of height adjustment, this embodiment has innovatively designed the height adjustment method. Specifically, the telescopic mechanism 3 includes a first pole 301, a second pole 302, and a through hole 303 , a limit pin 304, a return force spring 305, the top rear end of the first partition 2 is fixedly connected with a first pole 301, and the inside of the first pole 301 is plugged with a second pole 302, and the first pole 301 and The corresponding positions on the left and right sides of the second pole 302 are provided with a plurality of groups of through holes 303, and the inside of the through holes 303 is inserted with the limit pin 304, and the retaining ring of the limit pin 304 is fixedly connected with the first pole 301. There is a return spring 305, a first pole 301 and a second pole 302 are provided, the second pole 302 is plugged into the inside of the first pole 301, and the...

Embodiment 3

[0041] refer to figure 2 In this embodiment, on the basis of Embodiment 2, in order to achieve the purpose of dehumidification, this embodiment has innovatively designed the dehumidification method. Specifically, the dehumidification mechanism 12 includes an installation groove 1201, a dehumidification filter element 1202, and the interior of the first drawer 11 Mounting grooves 1201 are provided on the left and right sides, and a dehumidification filter element 1202 is clamped inside the installation groove 1201. The installation groove 1201 is provided. The installation groove 1201 is used for installing the dehumidification filter element 1202. Air is absorbed so as to ensure that the drawings stored in the first drawer 11 are always in a dry state.

[0042] refer to figure 1 , in order to achieve the purpose of closing the toolbox, the front lower end of the case cover 9 in this embodiment is fixedly connected with an upper buckle 19, and the front upper end of the box b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com