Leveling device, system and method

A leveling device and leveling technology, applied in auxiliary devices, workbenches, auxiliary welding equipment, etc., can solve the problems of complex structure, unsuitable nuclear structure welding conditions, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

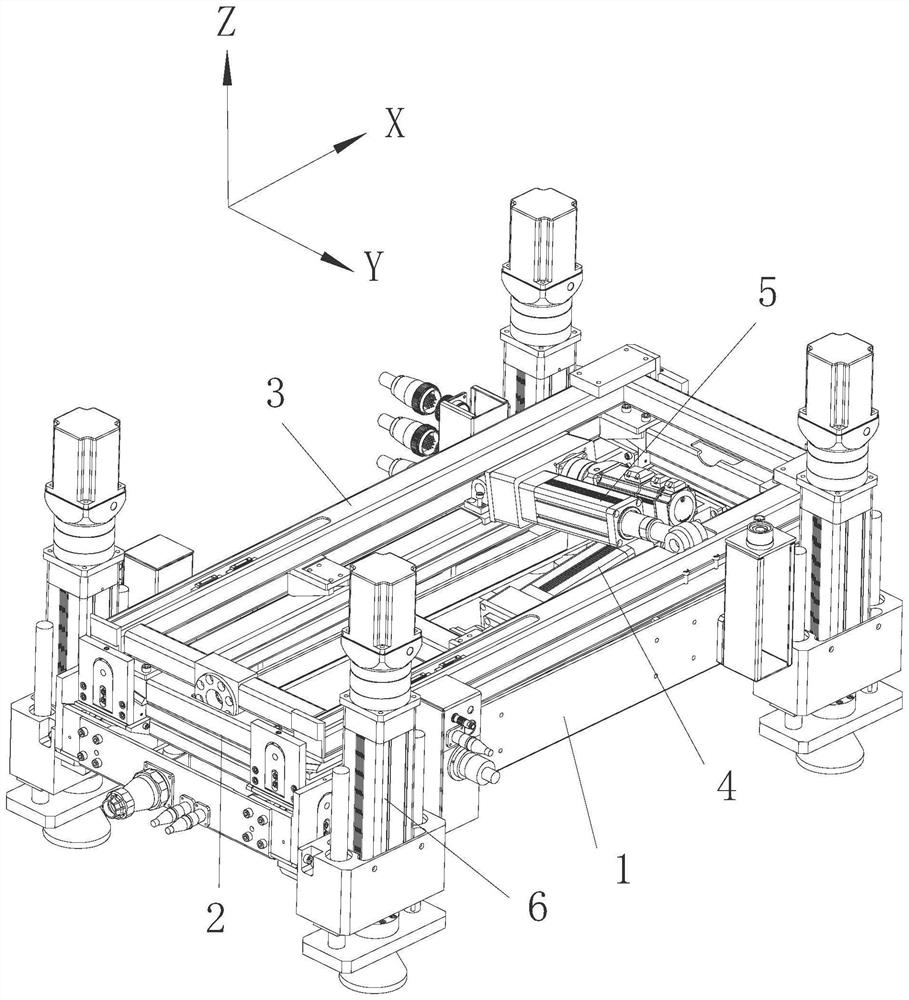

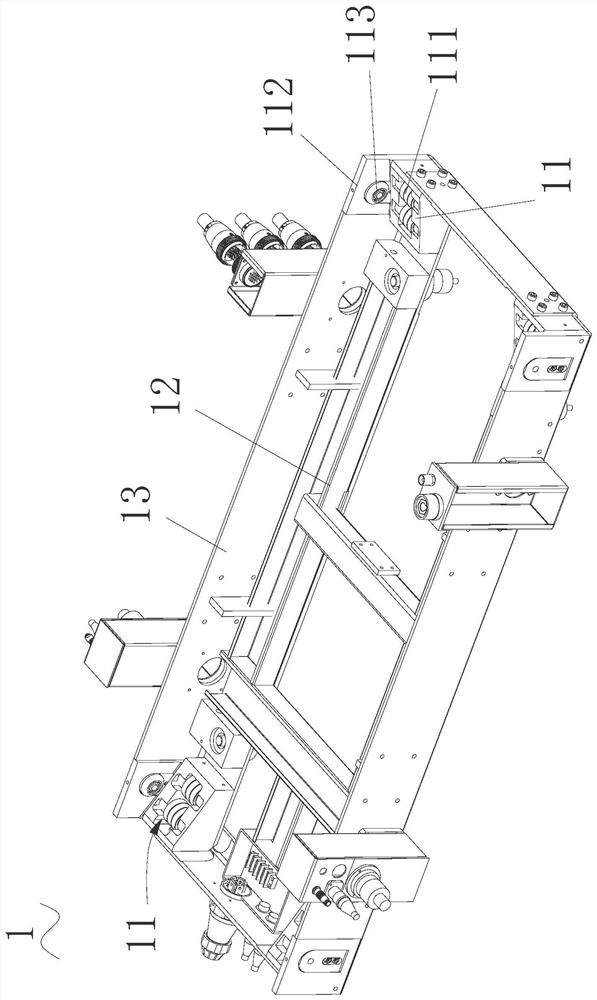

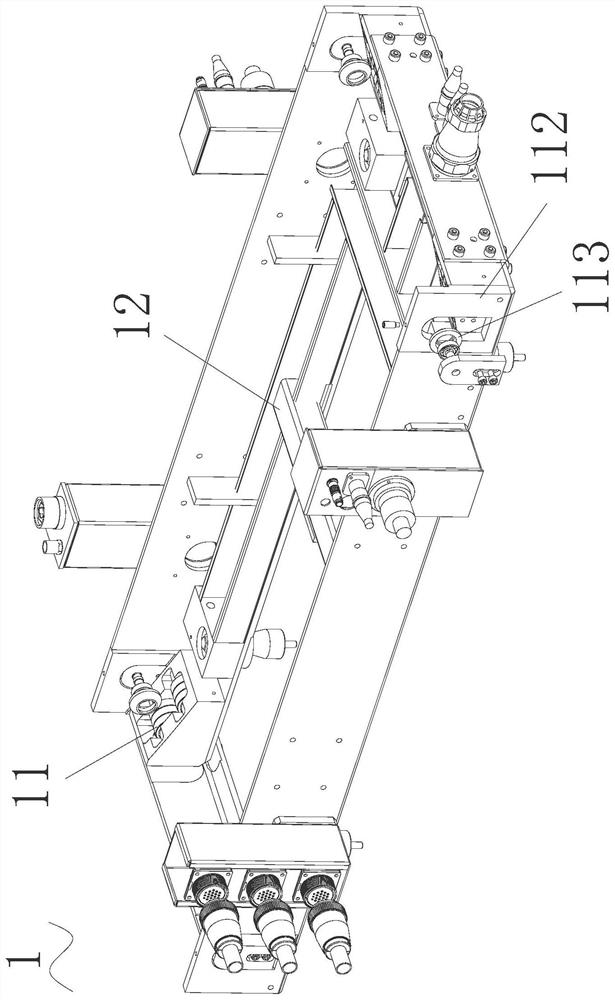

[0078] Such as figure 1 As shown, this embodiment provides a leveling device, including: a fixed platform 1 , a mobile platform 2 , a worktable 3 , an X-direction driving mechanism 4 , a Y-direction driving mechanism 5 and an initial adjustment mechanism 6 .

[0079] The fixed platform 1, the mobile platform 2 and the working platform 3 are stacked sequentially from bottom to top to form a cube structure. When the cube structure is supported on a horizontal plane, set up a Cartesian coordinate system with its length direction as the X direction, its width direction as the Y direction, and its height direction as the Y direction to illustrate the leveling device of this embodiment:

[0080] Both ends of the top surface of the fixed table 1 along the X direction of the horizontal plane have a first inclined surface or a first concave arc surface, and the distal end of the first inclined surface or the first concave arc surface along the X direction is inclined upward relative to...

Embodiment 2

[0125] This embodiment provides a leveling system, including a spirit level, a control system, and the leveling device of Embodiment 1;

[0126] In this embodiment, the level is specifically a horizontal gyroscope, and the level is arranged on the top surface of the workbench 3 of the leveling device and is electrically connected to the control system, and is used to detect the levelness of the workbench 3 along the X direction and to detect the level of the X direction. The levelness signal is transmitted to the control system, and is used to detect the levelness of the workbench 3 along the Y direction and transmit the detected Y levelness signal to the control system,

[0127] The control system is electrically connected with the X-direction drive mechanism 4, and is used to control the X-direction drive mechanism 4 to act according to the X-direction level signal, so as to drive the four first sliders 22 at the bottom of the mobile platform 2 on the corresponding first slid...

Embodiment 3

[0133] This embodiment provides a method for leveling the leveling system of Embodiment 2, including the following steps:

[0134]The spirit level detects the levelness of the workbench 3 of the leveling device along the X direction and transmits the detected X-direction levelness signal to the control system, and the control system controls the X-direction drive mechanism 4 according to the X-direction levelness signal to drive the mobile platform 2. The four first slide blocks 22 at the bottom slide on the corresponding first slide 11 on the top of the fixed table 1 until the top surface of the workbench 3 is kept horizontal along the X direction;

[0135] The level gauge detects the levelness of the workbench 3 of the leveling device along the Y direction and transmits the detected Y-direction levelness signal to the control system, and the control system controls the Y-direction drive mechanism 5 according to the Y-direction levelness signal to drive the workbench 3. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com