Arch rib support for large-span steel tube arch bridge assembling construction

A steel tube arch bridge and long-span technology, which is applied in the construction of arch bridges, bridges, and bridges, can solve the problems such as the inability to adjust the height of the support surface, and achieve the effects of cost saving, improving utilization rate and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

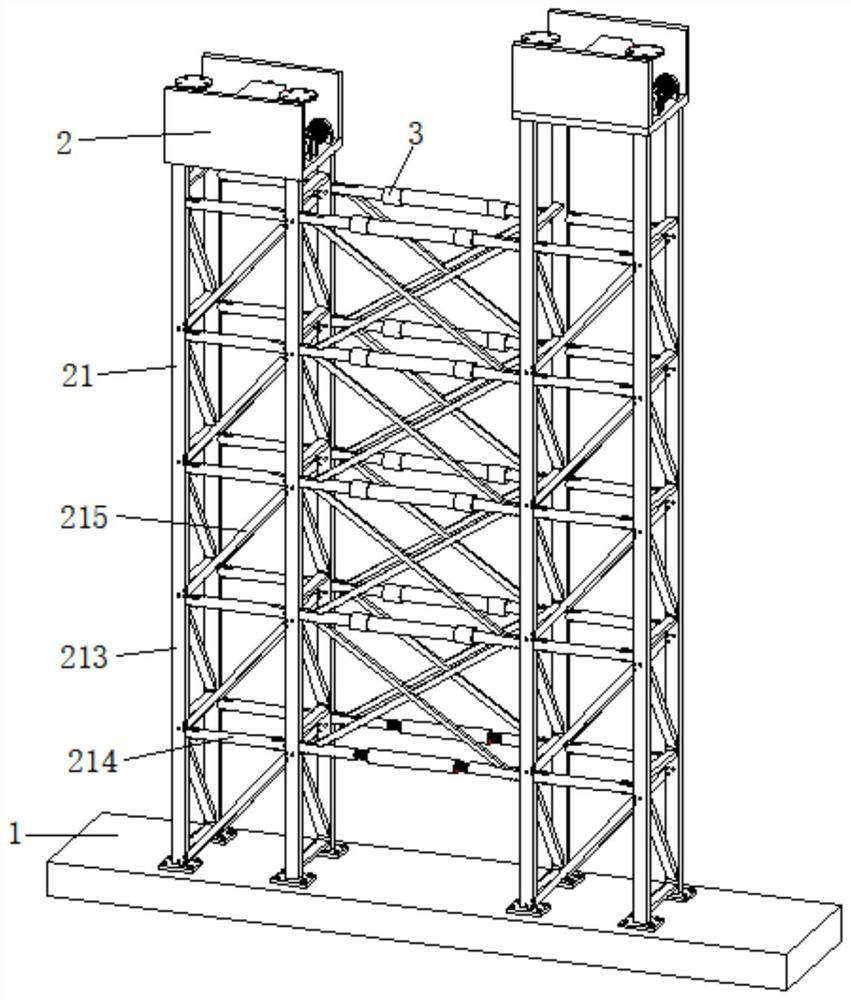

[0030] The invention provides an arch rib support for assembly construction of a large-span steel pipe arch bridge, specifically as Figures 1 to 4 As shown, it includes a base 1 and multiple sets of support units 2 with different heights arranged on the base 1. The adjacent two sets of support units 2 are connected by multiple sets of connection modules 3, and multiple sets of support units 2 form an arched support structure. Multiple sets of supporting units with different heights support the arch ribs;

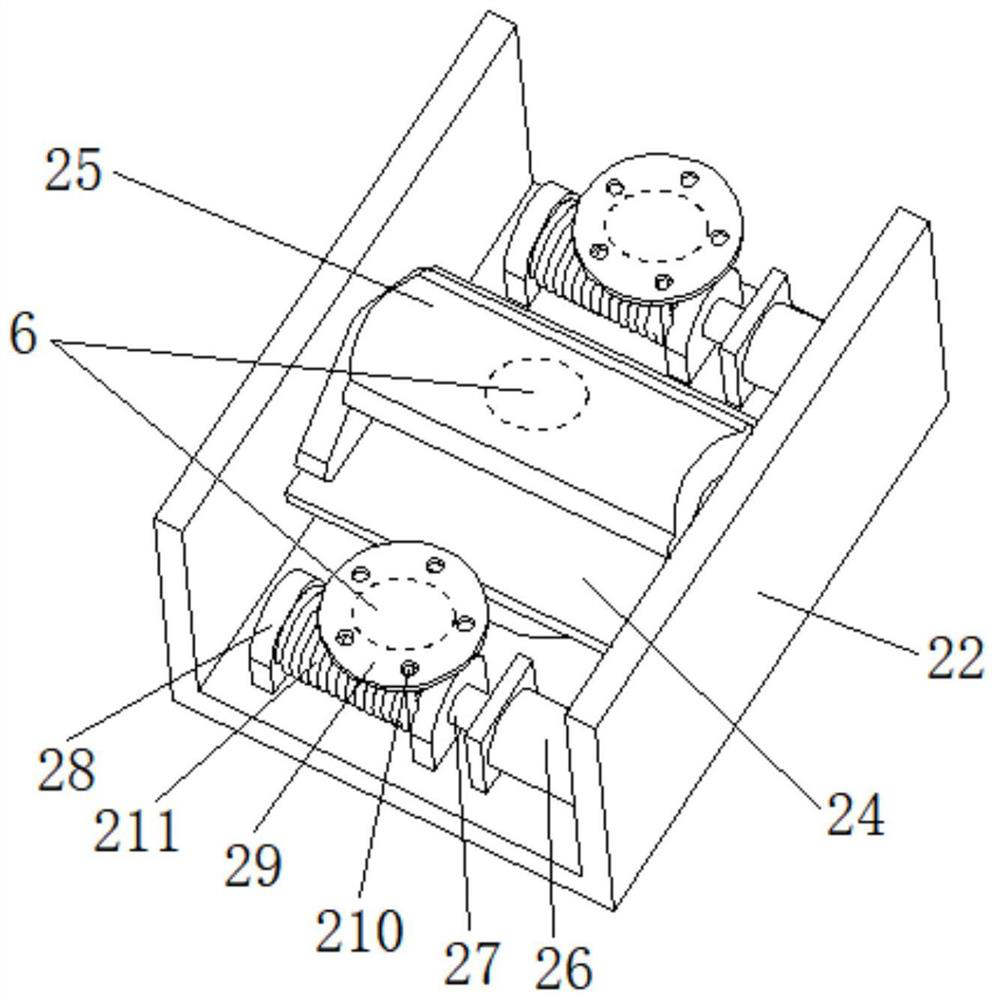

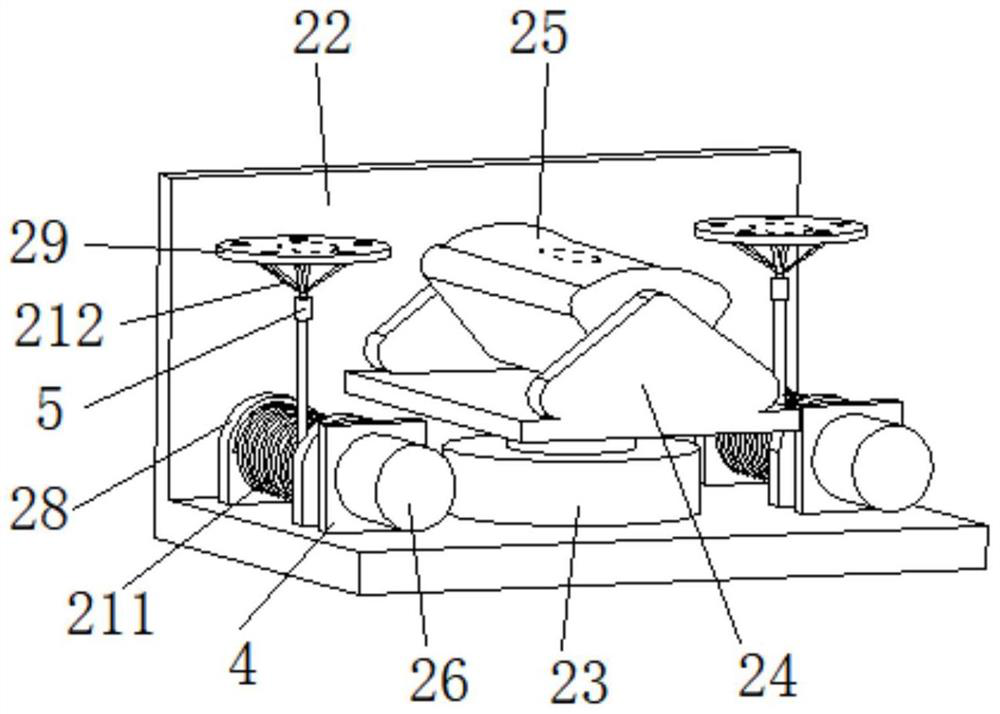

[0031] Each set of supporting units 2 includes a support frame 21 and a U-shaped brace 22 arranged on the top of the brace 21. The opening of the U-shaped brace 22 faces the length direction of the arch rib. The U-shaped brace 22 is provided with a height adjustment module and a device Height fine-tuning modules on both sides of the height-adjusting module; The top of the force block is an arc-shaped structure matched with the arch rib, and the support is more stable; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com