Circular track crane and assembling method and disassembling method of circular track crane

An assembly method and a crane technology, applied in the direction of cranes and the like, can solve the problems of increasing the assembly and disassembly cost and floor space of the ring rail crane, increasing the difficulty of installation and disassembly of the ring rail crane, and the large lifting capacity of the ring rail crane, and achieving the improvement of the ring rail crane. The effect of equipment operation economy, reduction of assembly site, and less space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

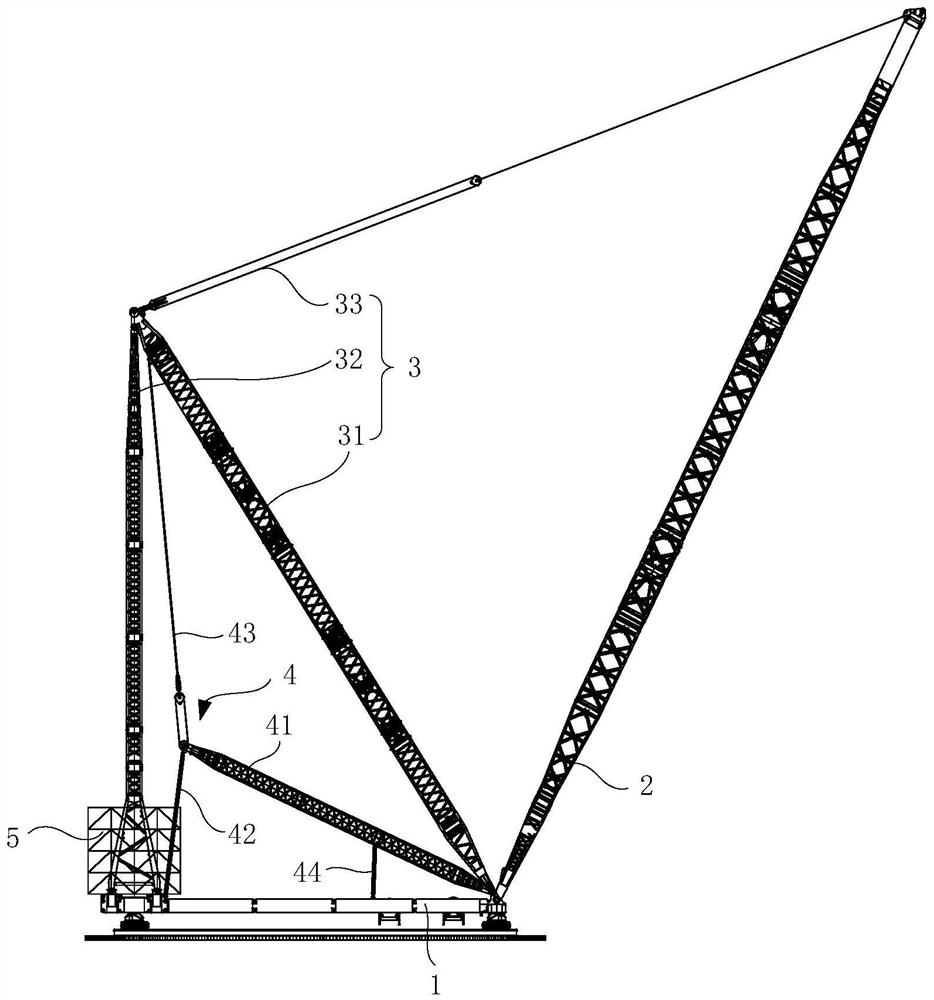

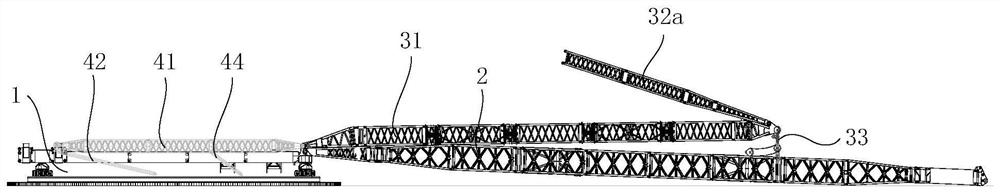

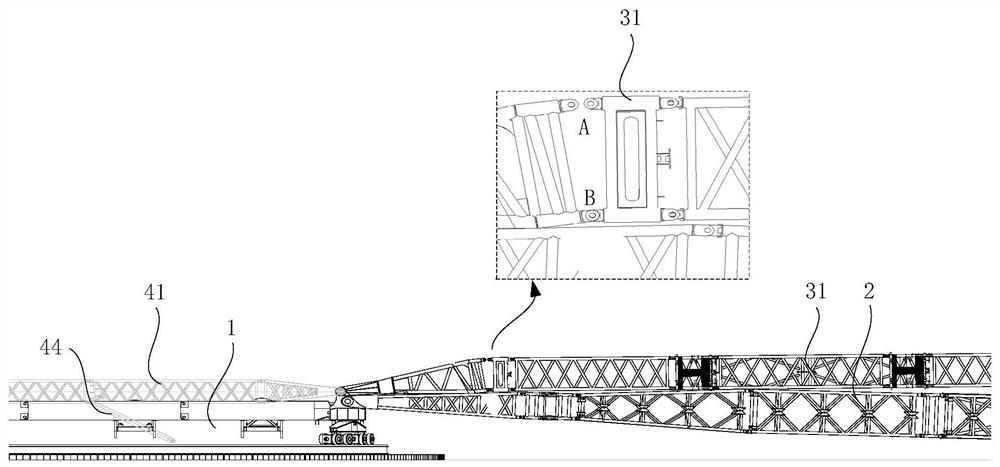

[0071] Combine below Figure 1 to Figure 10 The technical solution provided by the present invention is described in more detail.

[0072] An embodiment of the present invention provides a ring rail crane, including a platform 1 , a mast system 3 , a jib frame 2 and a support frame system 4 . Platform 1 is configured to provide support. The jib frame 2 is installed on the platform 1 . The mast system 3 is installed on the platform 1 . The mast system 3 is configured to realize boom raising, working and lowering of the jib frame 2 . The support frame system 4 is installed on the platform 1; the support frame system 4 is configured to realize the raising and lowering of the mast system 3 .

[0073] Ring rail cranes run on a circular track. The maximum hoisting weight of the ring rail crane can reach more than 3000 tons. The size of the platform 1 matches the size of the track and is positively related to the maximum hoisting weight of the ring rail crane. The bottoms at b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com