Speed coupling slip frequency double-speed reducer

A reducer and slip technology, applied in the field of mechanical reducers, can solve the problems of not meeting the needs of use, difficult to couple multiple input speeds, and unable to effectively meet the needs of use, etc., and achieve the effect of compact structure, small volume and accurate slip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

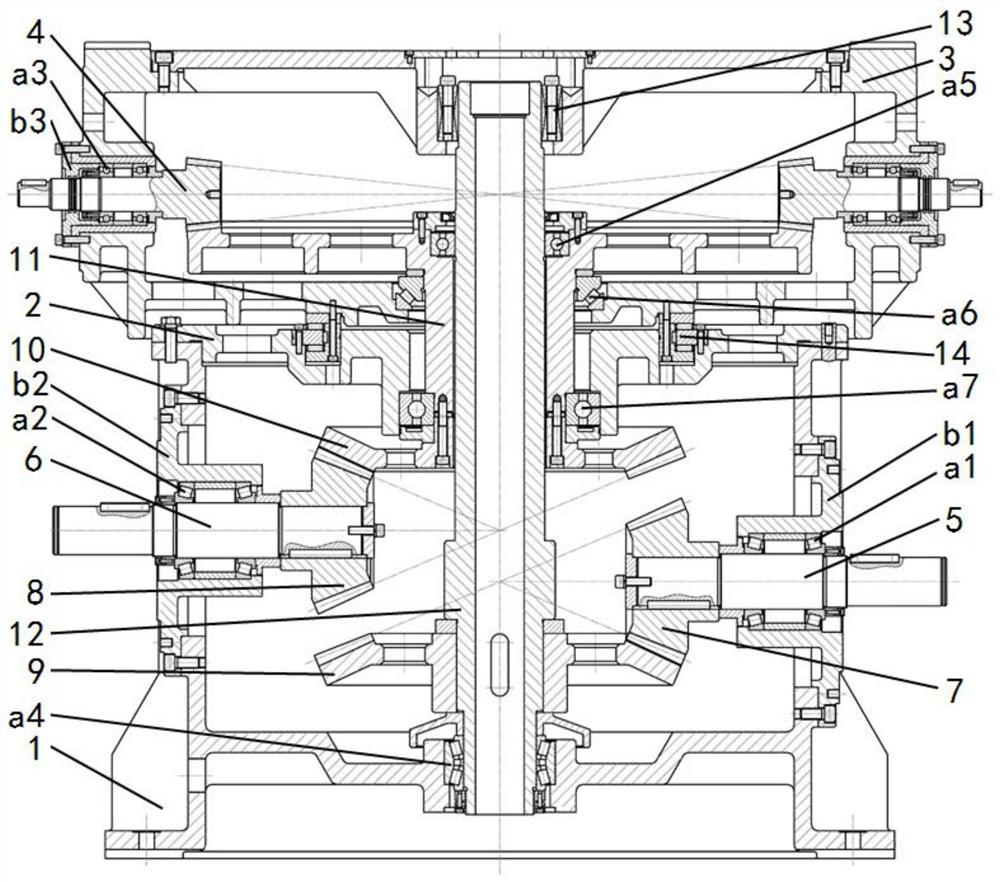

[0023] A slip two-speed reducer, such as figure 1 As shown, the reducer includes a revolution input shaft 5, an autorotation input shaft 6, an output shaft 4, a main shaft 12, a frame 1, an inner cover 2, a box cover 3, a bevel gear, a bearing, a gland, an expansion sleeve 13, and a flat key and screws. The frame 1 and the inner cover 2 are fixed, the box cover 3 rotates on the inner cover 2, the revolution input shaft 5 and the rotation input shaft 6 are connected to the frame 1 through the bearing and the gland, and the output shaft 4 is connected to the box through the bearing and the gland The cover 3 rotates together with the box cover 3, and the inside of the reducer is driven by three pairs of bevel gears. By separately controlling the rotational speeds of the revolution input shaft 5 and the autorotation input shaft 6, the continuous adjustment of the revolution speed, autorotation speed and slip of the output shaft 4 is realized.

[0024] Specifically, the frame 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com