Centrifugal blade wheel blade tip clearance matching method

A centrifugal impeller and blade tip clearance technology, which is applied in the direction of mechanical clearance measurement, instruments, and measuring devices, can solve the problems of difficult selection of centrifugal impeller blade tip clearance, inaccurate calculation method of size chain, and inability to select reference points, etc., to achieve Avoid cumulative tolerances, small errors, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

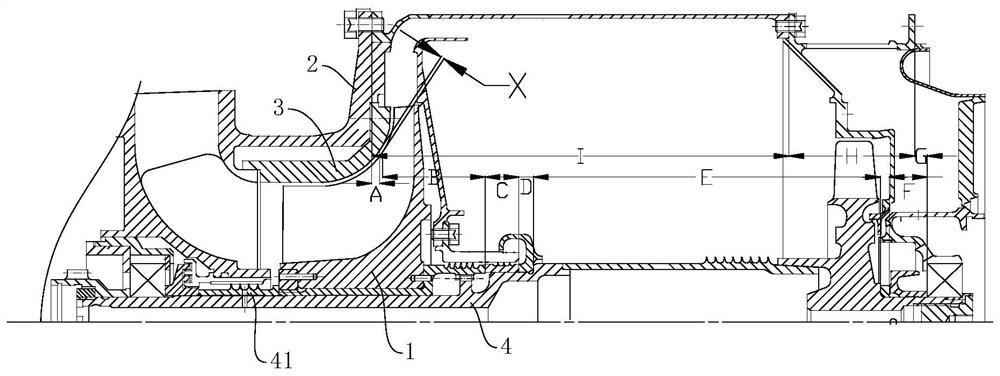

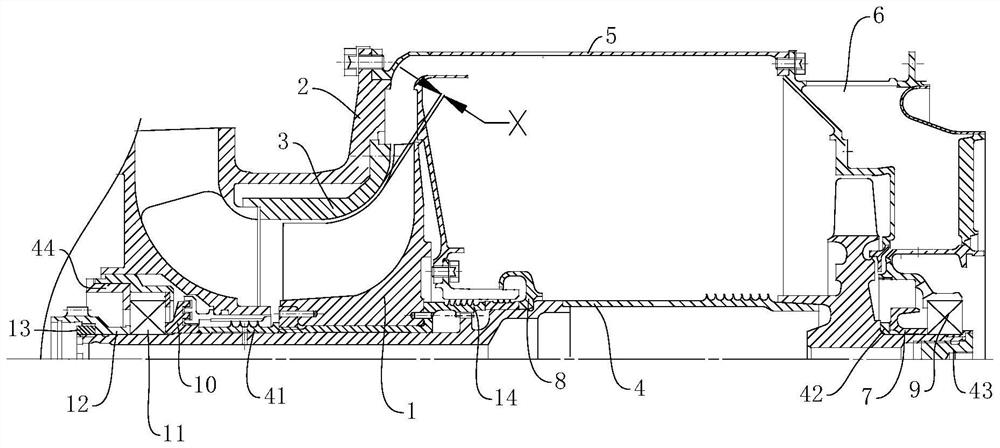

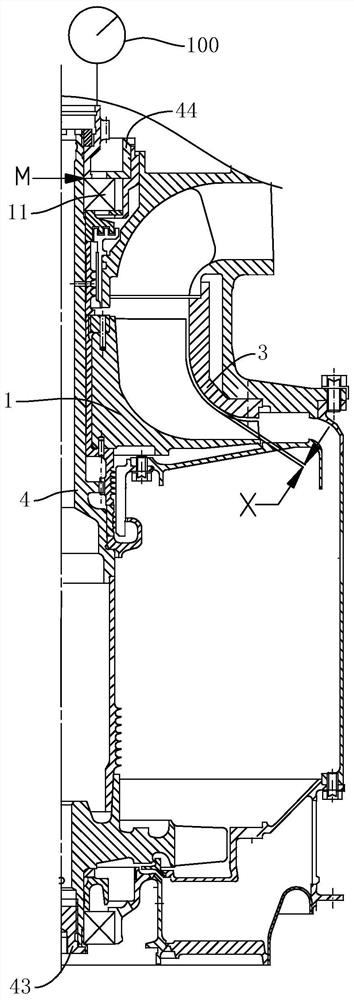

[0033] Such as figure 2 As shown, the embodiment of the present invention provides a centrifugal impeller blade tip clearance matching method, and the two fulcrum bearings of the engine rotor are associated with the engine stator and the rotor 4 ( Figure 5 ), the rotor 4 is pretended to be installed in the engine casing, and the axial movement of the rotor 4 is used to move the rotor 4 axially so that the centrifugal impeller 1 ( Figure 4 ) and the impeller cover 3 are in the first tight fit state, and the first axial moving distance of the rotor 4 is measured in the first tight fit state; according to the design requirements of the component structure, by tightening the compression nut of the bearing pressure plate 44, the rotor 4. Move the axial direction fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com