Layered quantitative sampling device for petroleum detection

A quantitative sampling and petroleum technology, applied in sampling devices and other directions, can solve problems such as difficulty in control, and achieve the effect of easy cleaning and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

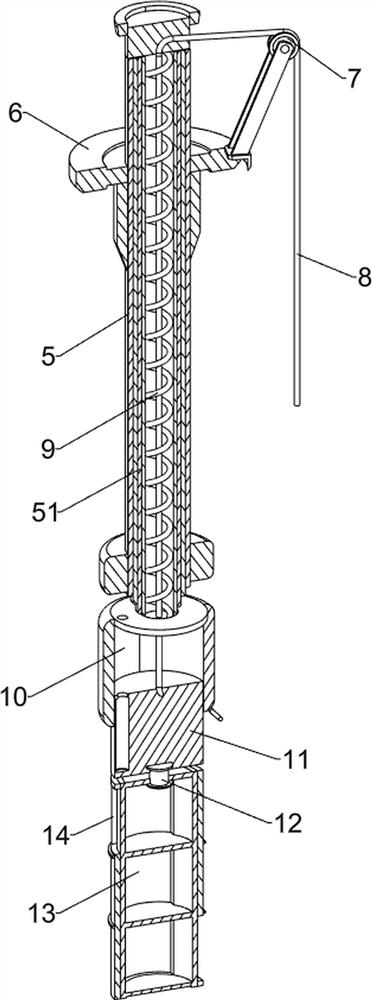

Embodiment 1

[0040] A layered quantitative sampling device for petroleum detection, such as Figure 1-7 As shown, it includes a fixed frame 1, a first connecting plate 2, a connecting frame 3, a fixed plate 4, a fixed rod 5, a first telescopic rod 51, a second connecting plate 6, a pulley 7, a stay cord 8, and a first spring 9. , the third connecting plate 10, the first connecting block 11, the first rotating shaft 12, the charging frame 13, the casing 14, the lifting mechanism 15 and the rotating mechanism 16, the first connecting plate 2 is installed in the middle part of the fixed frame 1, and the fixed frame 1 The left and right sides of the middle part are equipped with a connecting frame 3, the connecting frame 3 is located at the outside of the first connecting plate 2, a fixed plate 4 is installed between the two connecting frames 3 tops, and a fixed rod 5 is installed in the middle of the fixed plate 4, inside the fixed rod 5 The first telescopic rod 51 is connected, the second co...

Embodiment 2

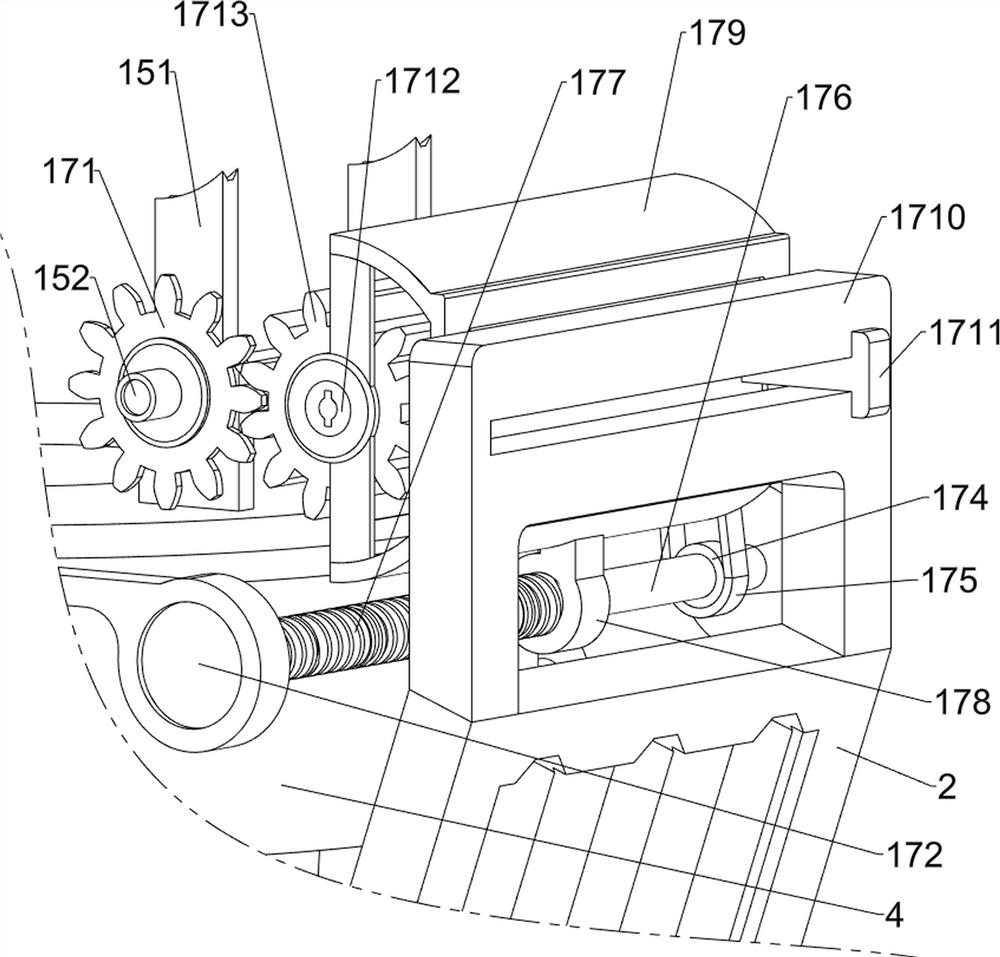

[0045] On the basis of Example 1, such as figure 1 , Figure 8 , Figure 9 and Figure 10 As shown, power mechanism 17 is also included, and power mechanism 17 includes spur gear 171, the 6th connecting plate 172, motor 173, belt pulley 174, flat belt 175, second rotating shaft 176, screw mandrel 177, nut 178, the 7th connection Plate 179, guide plate 1710, slider 1711, second telescopic rod 1712, long gear 1713 and missing gear 1714, the right side of the first connecting shaft 152 is equipped with a flat gear 171, the flat gear 171 is located on the left side of the chain 154, and the left and right sides of the fixed plate 4 The sixth connecting plate 172 is installed on both sides, and a motor 173 is installed on the top of the sixth connecting plate 172 on the left side. The motor 173 is used to provide driving force. A long gear 1713 and a missing gear 1714 are respectively installed on the bar 1712, the missing gear 1714 is located on the left side of the long gear 1...

Embodiment 3

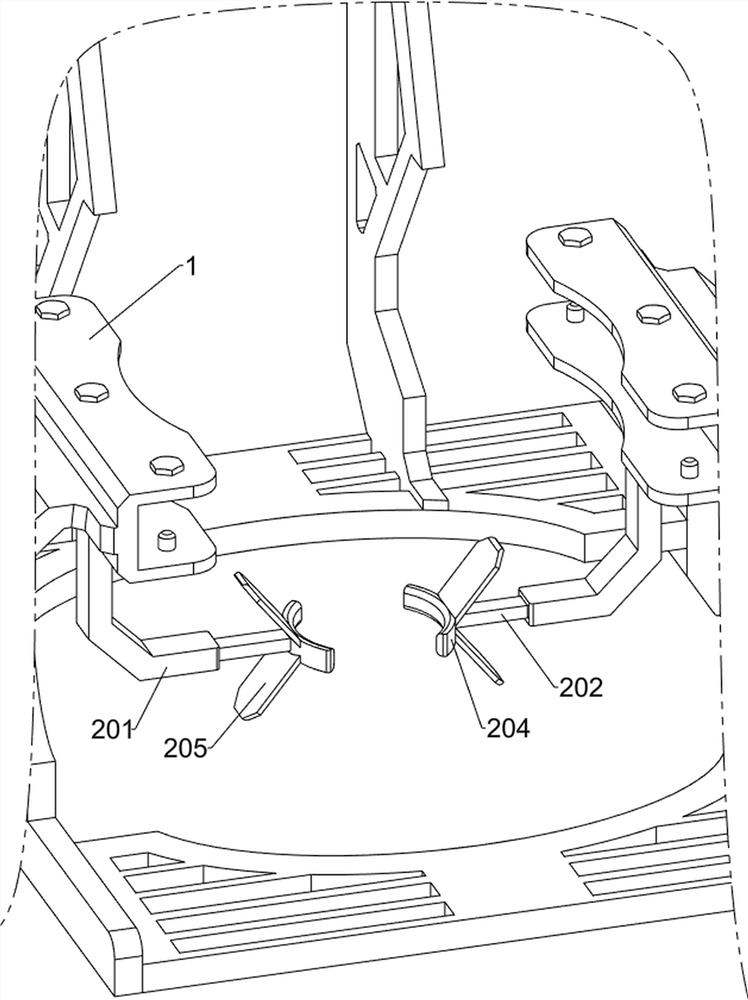

[0048] On the basis of Example 2, such as figure 1 and Figure 11 As shown, an anti-slip mechanism 18 is also included, and the anti-slip mechanism 18 is used to fix the first connecting shaft 152 to prevent the first connecting shaft 152 from rotating on its own. and the third spring 184, the ninth connecting plate 181 is installed between the middle parts of the two fourth connecting plates 151, and the middle part of the ninth connecting plate 181 is slidingly connected with an extrusion ball 182, and the middle part of the first connecting shaft 152 is equipped with a rotating plate 183 , a plurality of grooves are evenly spaced on the rotating plate 183, and the extrusion ball 182 is matched with the groove, and the extrusion ball 182 can be snapped into the groove, and a third spring is connected between the extrusion ball 182 and the ninth connecting plate 181 184 , the top end of the third spring 184 is connected with the ninth connecting plate 181 , and the bottom en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com