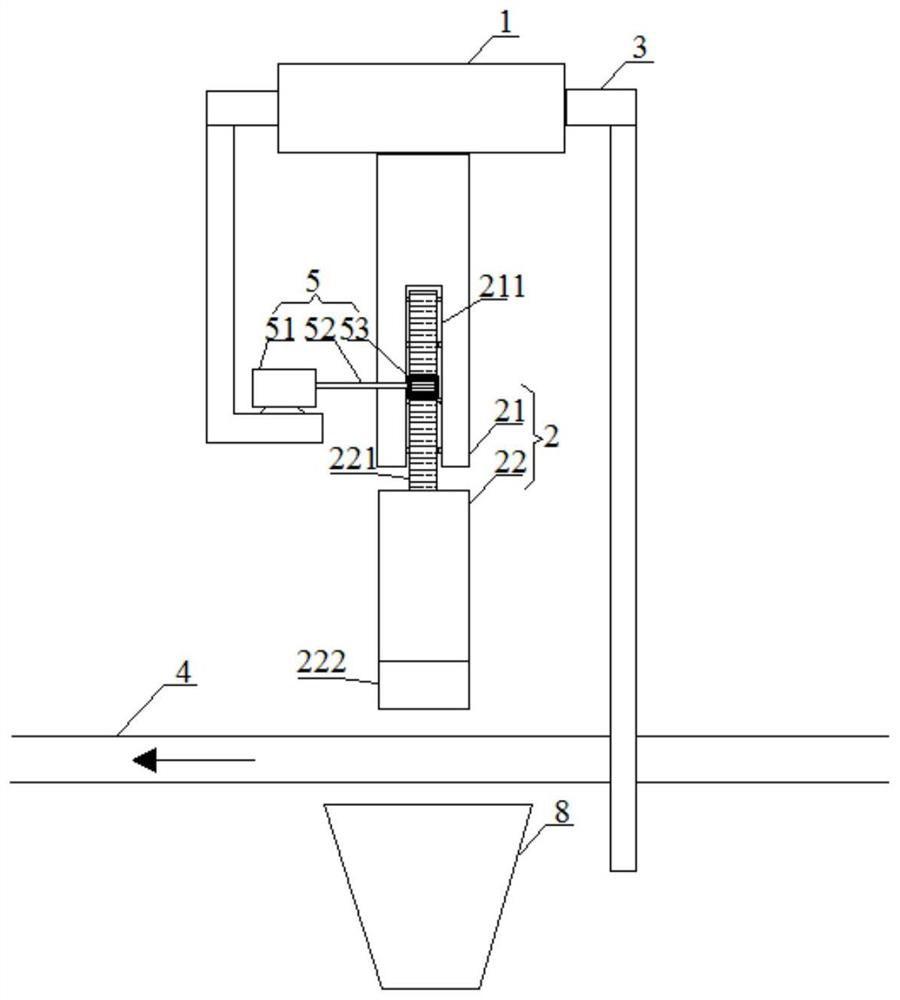

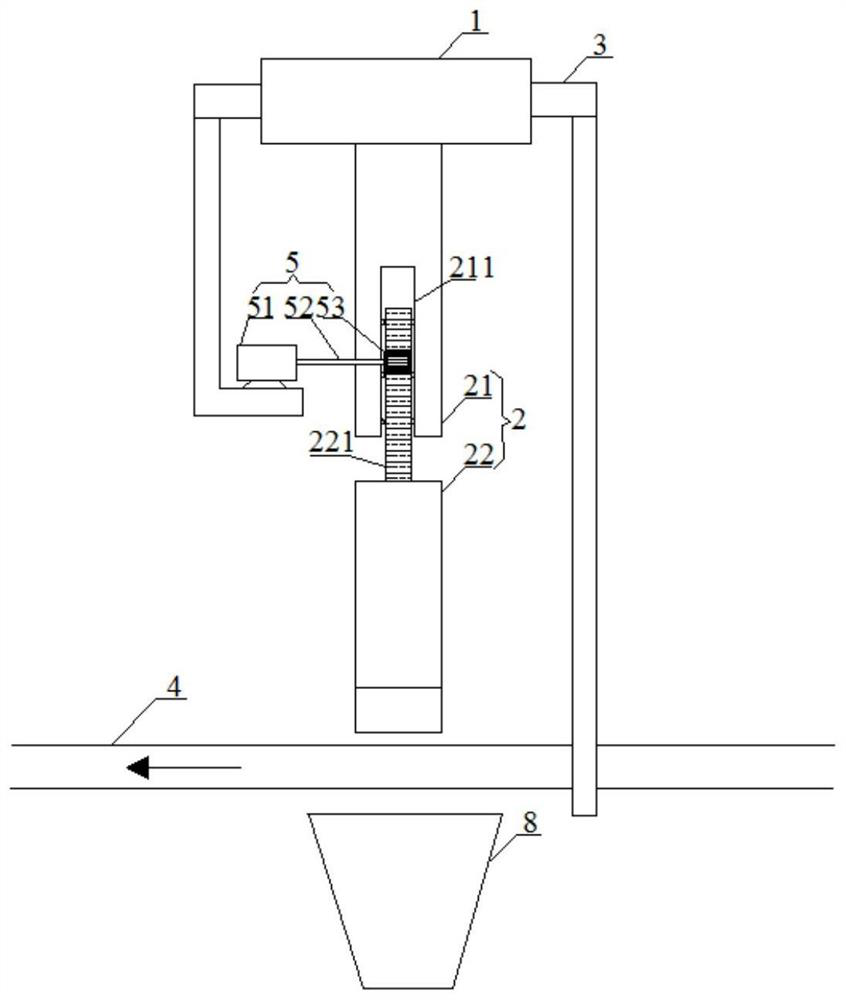

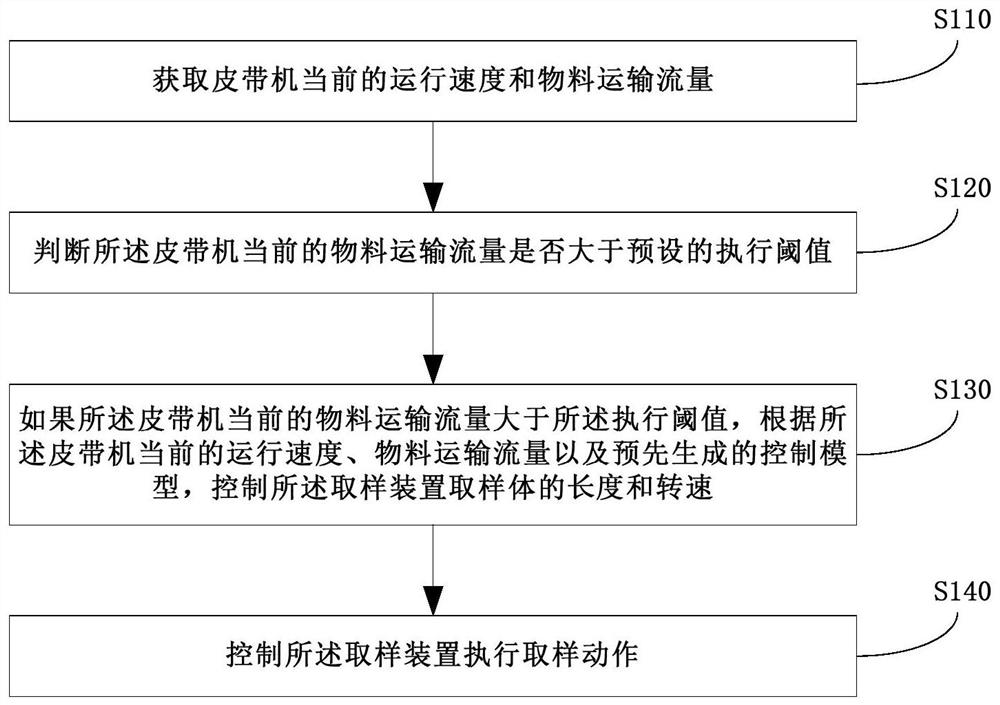

Sampling device, sampling control method and system for controlling the length of material transported by belt conveyor

A sampling device and sampling control technology, applied in sampling devices, transportation and packaging, measuring devices, etc., can solve the problems of poor sampling representativeness, sampling device can not control the sampling amount, etc., to avoid empty samples, timely sampling, and sample representative strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Belt conveyor is a typical material conveyor, which is commonly used in various production processes. For example, the sintering process of iron and steel enterprises. The sintering process of iron and steel enterprises involves batching, mixing, ignition, sintering and cooling. The raw materials used include iron-containing materials, fluxes and solid fuels. Usually, solid fuel coke powder for batching needs to be produced through the following process: Coarse coke trough—roller crushing—relay trough—four roll crushing—powder coke trough—batching, and the materials in the trough are generally transported to the next stage by a belt conveyor. One process, for example, uses a belt conveyor to transport the coke powder in the powder coke tank to the batching process.

[0057] For a long time, it has been generally accepted that the most suitable sintered fuel particle size is 0.5 mm to 3 mm. If the particle size is too large, the combustion speed will be slow, the combu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com