Glove structure and manufacturing method thereof

A glove and finger technology, applied in the manufacturing field of the aforementioned glove structure, to achieve the effect of good wearing experience, simple structure and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

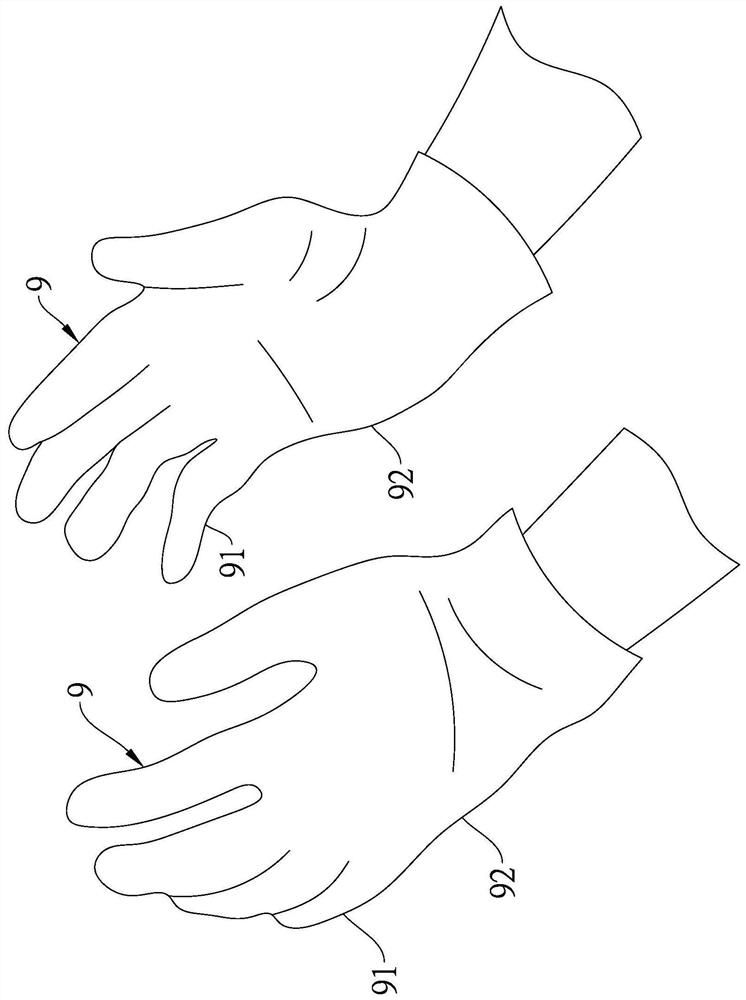

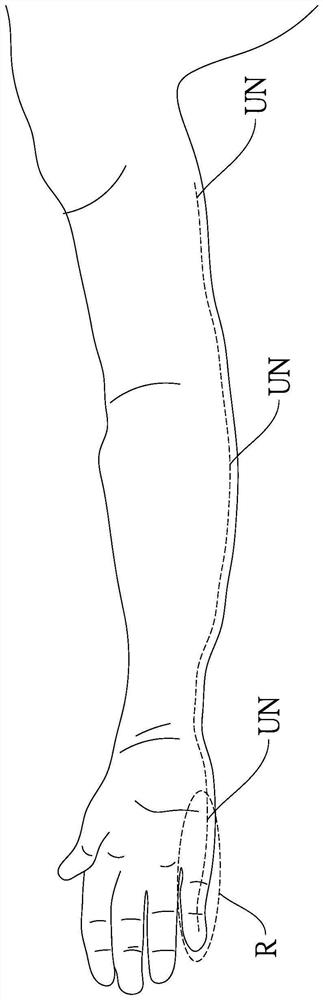

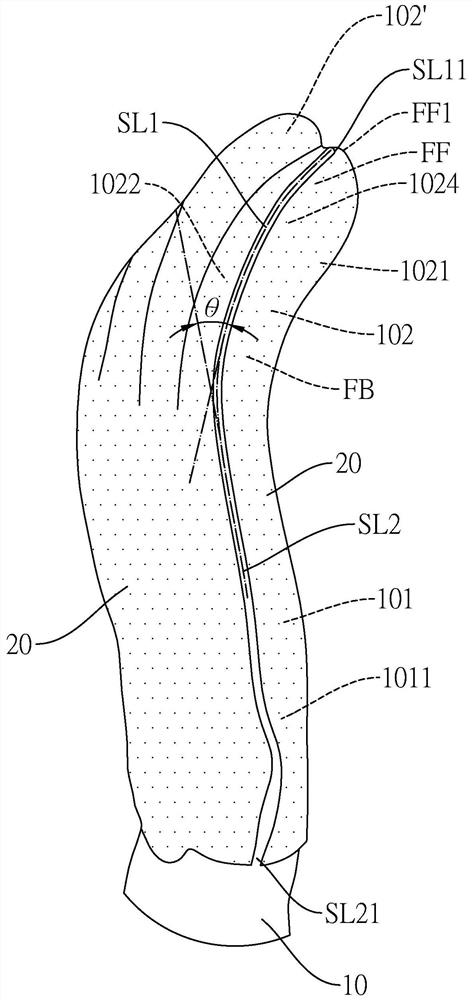

[0097] Please refer to the present invention Figure 2A , Figure 2B , Figure 2C , Figure 2D and image 3 , Figure 2A , Figure 2B , Figure 2C , Figure 2D and image 3 The details of the glove structure in the first embodiment of the present invention are shown. Such as Figure 2AThe glove structure of the first embodiment of the present invention includes a glove core 10 and an injection molding component 20 , wherein the injection molding component 20 covers at least a part of the glove core 10 . In the present invention, any object in the form of a glove is the glove core 10 referred to in the present invention. For example, the glove core 10 can be a fabric made of cotton yarn, leather, plush, fiber, natural fiber, artificial fiber or non-woven fabric. The glove core 10 can be a knitted glove, sewing glove or woven glove, or a Chinese invention Patent No. 102754946 announced the dip coated gloves, for example, the outer surface of the knitted gloves formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com