Waste express package recycling equipment

A recycling equipment and packaging technology, applied in the direction of solid separation, separating solids from solids with airflow, presses, etc., can solve the problems of not being able to distinguish, and achieve a good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

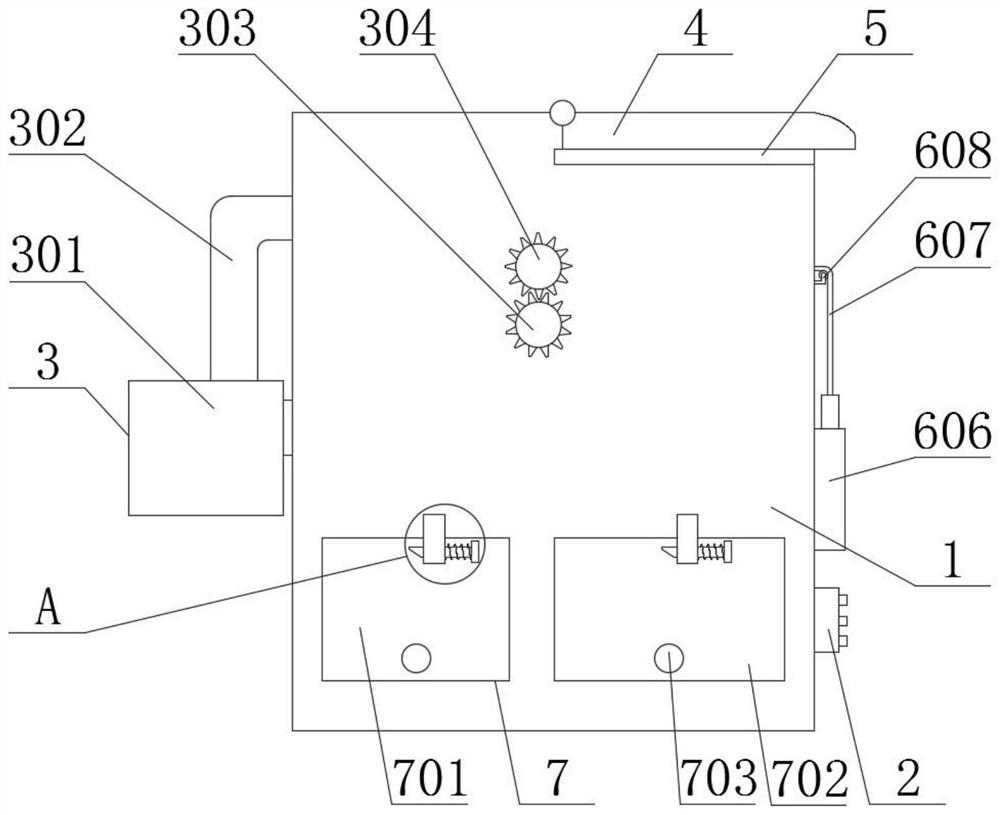

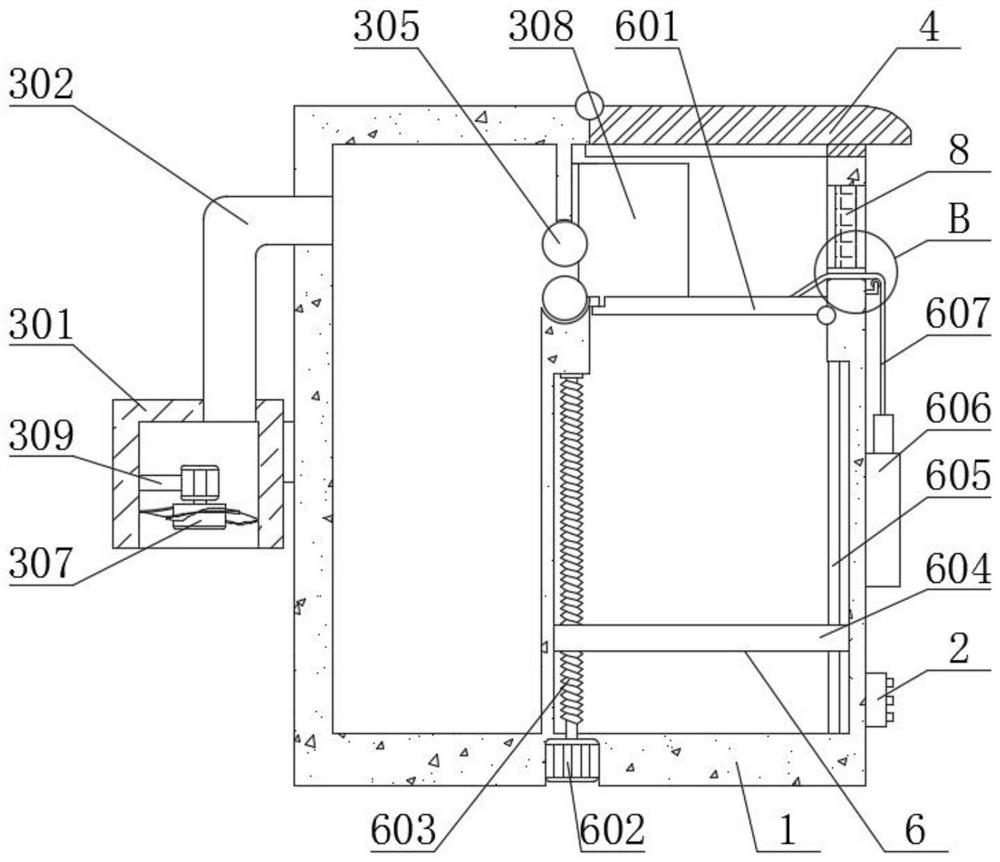

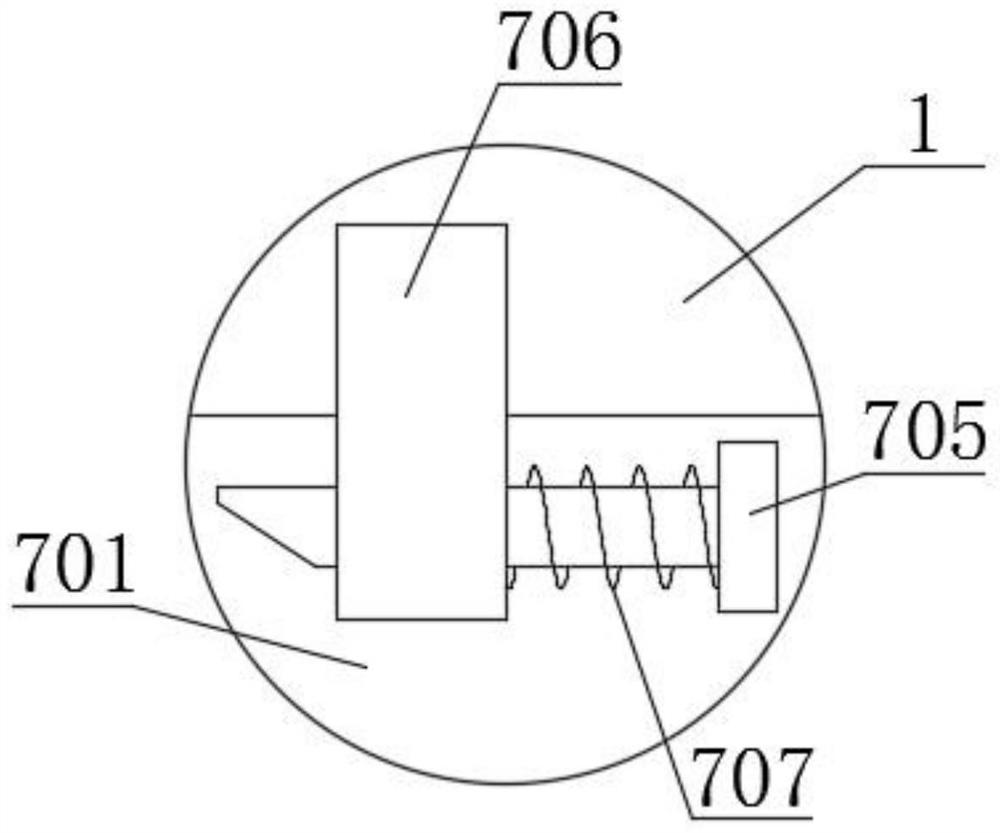

[0028] see Figure 1-7 , the present invention provides a technical solution:

[0029] A recycling device for waste express packaging, comprising a housing 1 and a control processor 2 located at the right end of the housing 1. The top right side of the housing 1 is hinged and connected with an opening cover 4, which is used for putting in the express packaging. , the inner side of the right end of the housing 1 is fixedly connected with a filter screen 8, the filter screen 8 is used to filter the dust entering the inner side of the housing 1, and the inner side of the housing 1 is provided with a plastic bag sorting device 3, a carton blanking device 6 and a discharge Mechanism 7, the plastic bag sorting device 3 includes a fan cover 301, a double output shaft motor 306, a material retaining slope 308 and a drive roller 305, the material retaining slope 308 is arranged on the inside of the top of the housing 1, and the material retaining slope 308 is arranged on the drive roll...

Embodiment 2

[0033] Workflow: in embodiment 2, the same part as embodiment 1 will not be repeated, the difference is that because the express plastic packaging may be covered at the entrance of the space on the left side of the housing 1 due to its large area, the present invention A transmission roller 305 is arranged at the entrance of the space on the left side of the housing 1, the transmission roller 305 works simultaneously with the fan 307, the double output shaft motor 306 rotates, and the double output shaft motor 306 simultaneously drives the transmission roller 5 and the driving gear 303 located on the lower side Rotate, the driving gear 303 drives the outer driven gear 304 to rotate, and the driven gear 304 drives the transmission roller 305 on the upper side to rotate. This transmission mode makes the transmission roller 305 on the upper side and the transmission roller 305 on the lower side rotate. The direction of rotation is opposite, which can play a good drainage effect, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com