Resistance welding automatic developing production system for circuit boards

A production system and circuit board technology, applied in the field of circuit board processing, can solve the problems of poor process consistency, overall unsmooth, low efficiency, etc., and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

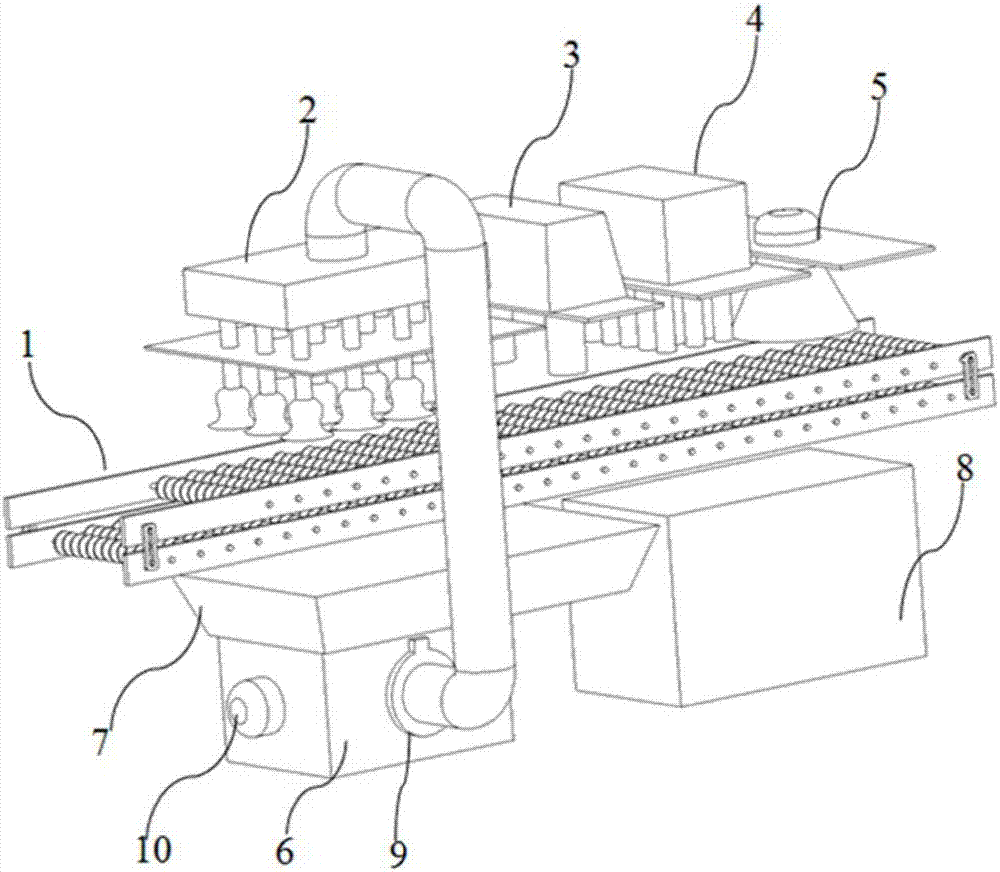

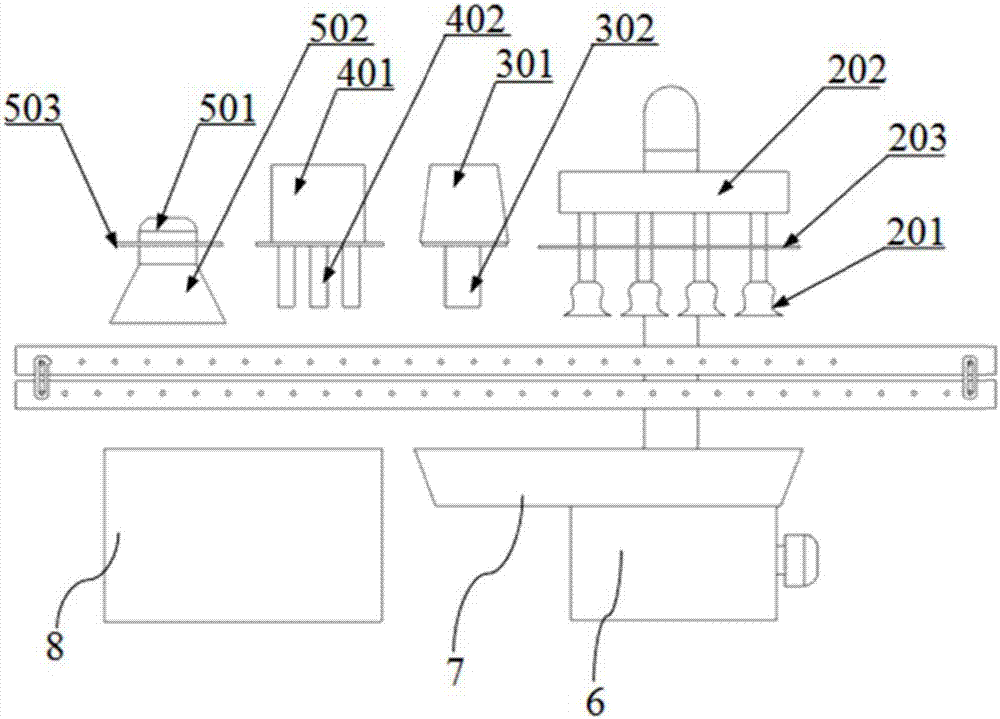

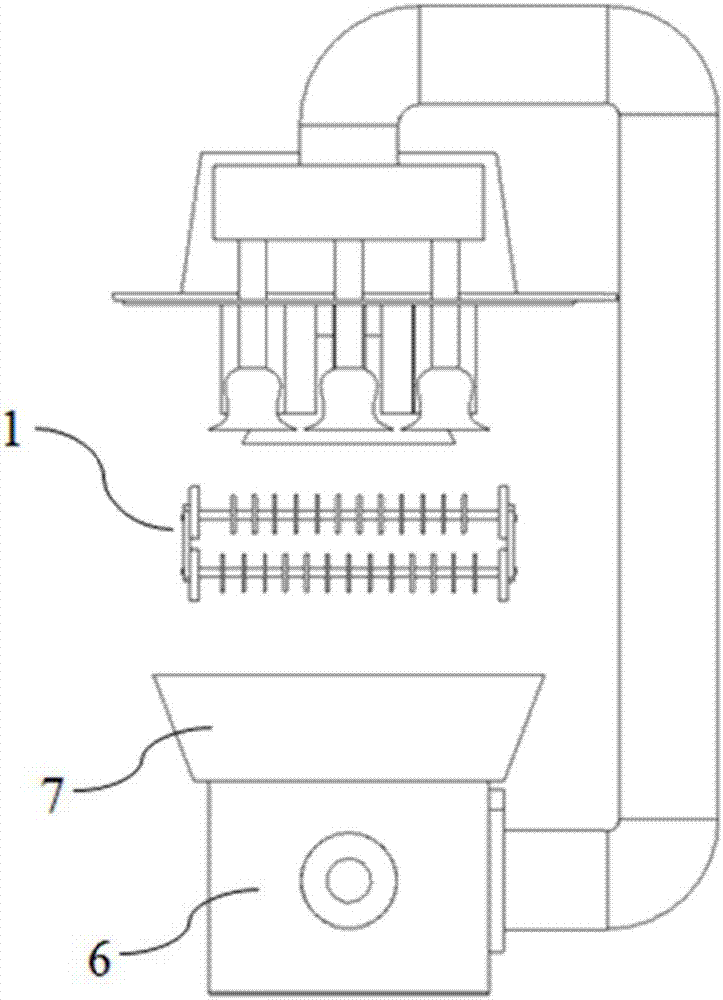

[0034] refer to Figure 1 to Figure 3 , an automatic development production system for circuit board solder resistance, including a system frame, a conveying mechanism 1, and a developing spray mechanism 2, an air blowing mechanism 3, and a water washing mechanism 4 arranged horizontally in sequence directly above the conveying mechanism 1 and drying mechanism 5,

[0035] The conveying mechanism 1 passes through the system frame and is arranged between the two side walls of the system frame; the developing spray mechanism 2 includes a lifting platform 203, a lifting motor and a spraying assembly, and the lifting motor is fixedly arranged on On the side wall of the system frame, the lifting platform 203 is movably connected between the side walls in the system frame, the lifting platform 203 is connected to the motor shaft of the lifting motor, and the spray assembly is arranged on the lifting platform 203. The spray assembly is connected to the development tank 6 located at t...

Embodiment 2

[0039] refer to Figure 1 to Figure 3 , an automatic development production system for circuit board solder resistance, including a system frame, a conveying mechanism 1, and a developing spray mechanism 2, an air blowing mechanism 3, and a water washing mechanism 4 arranged horizontally in sequence directly above the conveying mechanism 1 and drying mechanism 5,

[0040] The conveying mechanism 1 passes through the system frame and is arranged between the two side walls of the system frame; the developing spray mechanism 2 includes a lifting platform 203, a lifting motor and a spraying assembly, and the lifting motor is fixedly arranged on On the side wall of the system frame, the lifting platform 203 is movably connected between the side walls in the system frame, the lifting platform 203 is connected to the motor shaft of the lifting motor, and the spray assembly is arranged on the lifting platform 203. The spray assembly is connected to the developing tank 6 located at th...

Embodiment 3

[0046] This embodiment is improved on the basis of the second embodiment. refer to figure 1 and figure 2 , In this preferred embodiment, a filter 9 is provided at the connection between the liquid delivery pipeline and the developing tank 6 . A stirring blade is arranged in the developing tank 6, and the stirring blade is connected to a stirring motor 10 on the outer wall of the developing tank 6, and a heater is also arranged in the developing tank 6. Each shower head 201 in the shower assembly is connected with a pressure controller. By adding stirring blades, the uniformity of the developer can be improved; by adding a heater, the temperature of the developer can be controlled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com