Equipment and method for disassembling solar cell module

A technology of solar cell components and equipment, applied in the direction of electronic waste recycling, solid waste removal, recycling technology, etc., can solve the problems of easy generation of waste water and gas, high residual glue rate on the glass surface, and difficulty in obtaining a complete glass aluminum back field coating And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

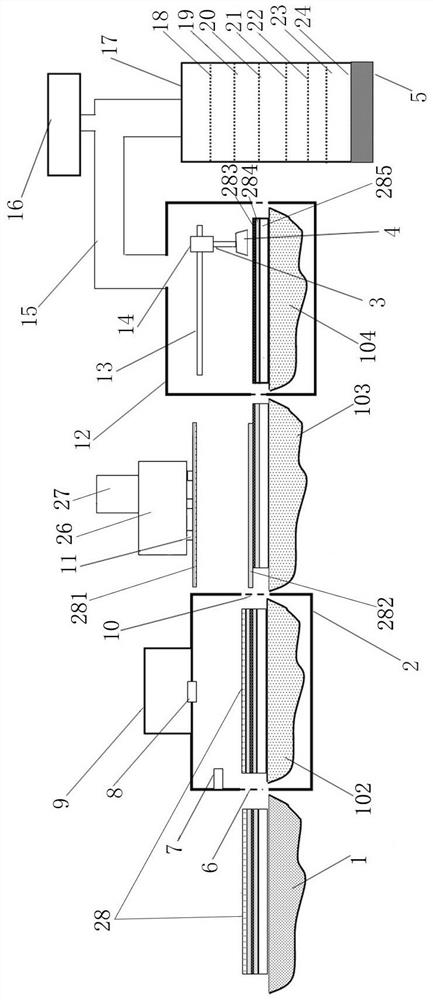

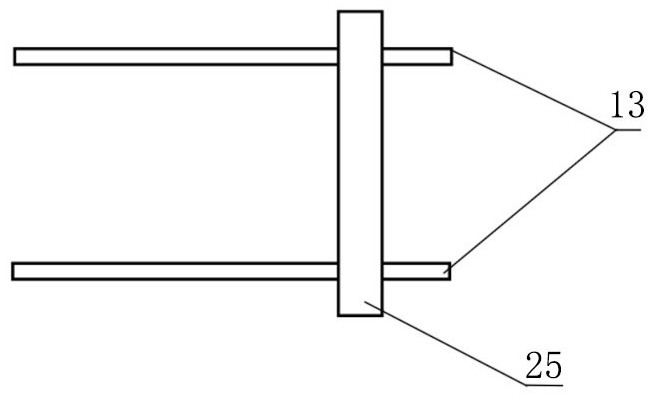

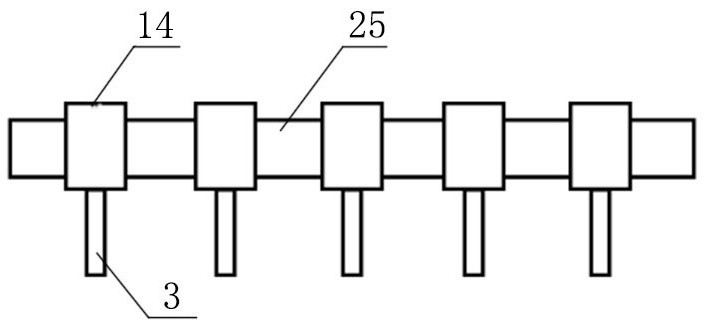

[0042] like figure 1 As shown, the apparatus of the present invention includes a feeding device, a low temperature treatment device 2, a collecting and conveying device, a grinding device 12 and a separating device. The solar cell assembly 28 includes a five-layer structure of a backplane 281, an underlying EVA film 282, a cell sheet 283, an upper cover EVA film 284 and a glass 285, wherein the cell sheet 283 includes an aluminum back field coating, metal bus strips, metal welding Belt and cell body.

[0043] The feeding device, the low-temperature processing device 2, the collecting and conveying device, and the rolling device 12 are all provided with a conveying platform for conveying the solar cell assembly 28 to the next device. The conveying platform includes a conveying motor and a conveying belt driven by the conveying motor. The width is equal to the width of the solar cell module 28 . The conveying platform 1 on the above-mentioned device can complete the conveying ...

Embodiment 2

[0050] The method for disassembling the solar cell assembly 28 of the present invention includes the following steps:

[0051]a. Prepare the equipment for disassembling the solar cell assembly 28 described in Example 1, place the glass 285 of the solar cell assembly 28 face down on the first conveying platform 1 of the feeding device, the first conveying platform 1 and the low temperature processing device The second transfer platform 102 inside starts the transfer, and the solar cell assembly 28 is sent to the second transfer platform 102 in the cavity of the low temperature treatment device 2 through the feed port of the low temperature treatment device 2. The first transfer platform 1 and the second transfer platform 102 stops the operation, and then closes the inlet and outlet 10 of the low temperature treatment device 2 .

[0052] b. The low temperature processing device 2 realizes an adjustable temperature between -80°C and -150°C in the cavity through the liquid nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com