Automobile sealing part recycling and crushing device

A pulverizing device and sealing technology, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of hindering the recycling process, incomplete pulverization, poor pulverizing effect, etc., so as to improve the pulverizing effect and speed up the recycling process. , the effect of speeding up the filtering speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

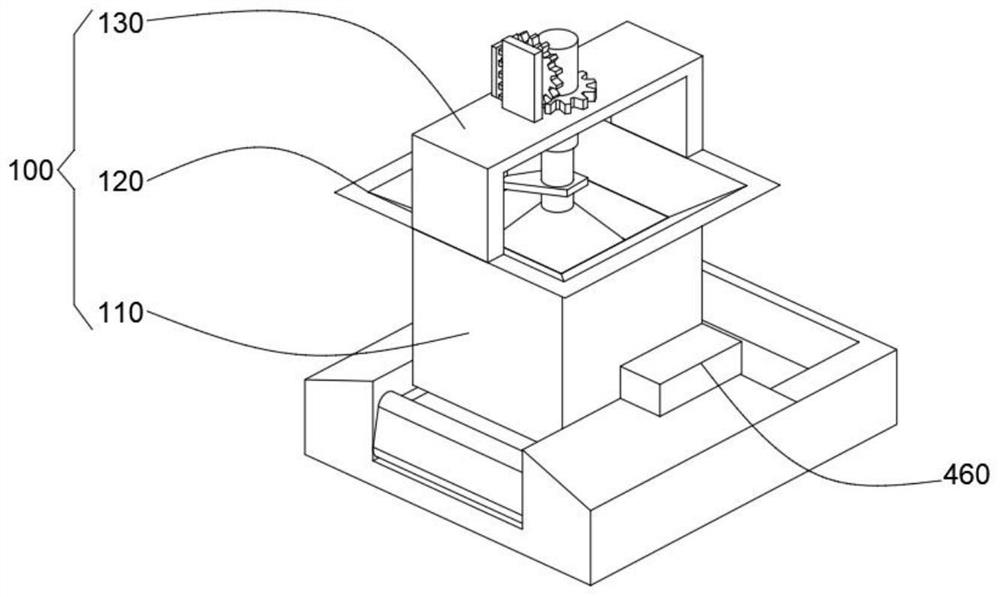

[0050] combine Figure 1-8As shown, the present invention provides a recycling and crushing device for automobile seals, including a skeleton module 100, a shredding module 200, a displacement module 300 and a screening module 400. The skeleton module 100 includes a housing 110 and is installed in the housing The hopper 120 at the top of the body 110 and the U-shaped plate 130 installed on the top of the hopper 120, both sides of the housing 110 are provided with rectangular openings; the housing 110 and the hopper 120 are used to accommodate the seal, so that the seal Can be effectively broken, the U-shaped plate 130 is used to provide support for the displacement module 300, making the module structure more firm;

[0051] The shredding module 200 includes a rotating shaft 210 that is movably installed inside the casing 110 and extends to the rear side of the casing 110. The rotating shaft 210 is used to provide support for the first gear 220 and the extrusion plate 450, and ...

Embodiment 2

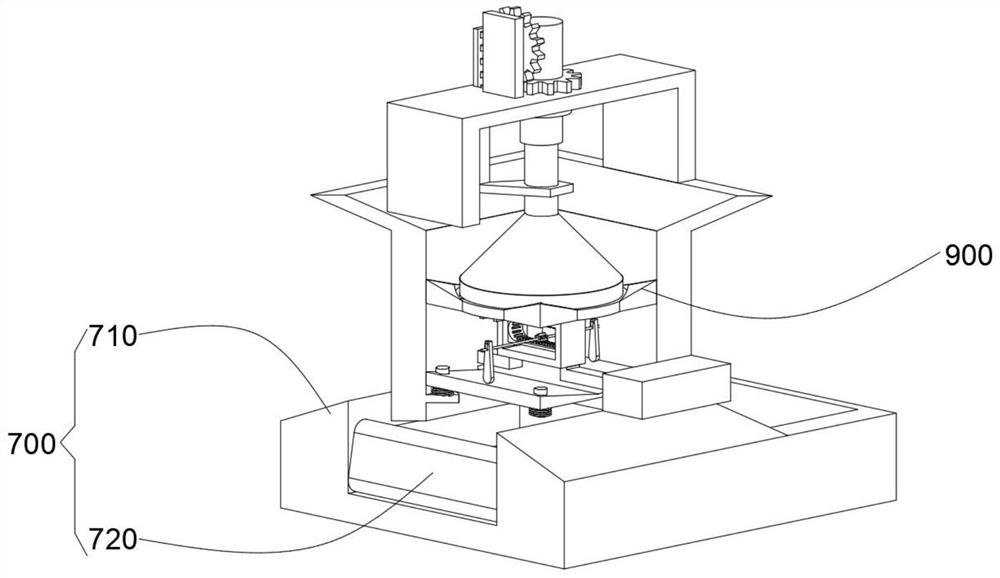

[0060] combine image 3 As shown, on the basis of the first embodiment, a plurality of connectors 900 are installed inside the housing 110, and the plurality of connectors 900 are all enclosed on the outside of the disc body 270. The connectors 900 are set in a fan shape, connected The connecting piece enables the tray 270 to be firmly installed inside the housing 110 , and at the same time, the connecting piece 900 enables the raw materials falling from the hopper 120 to drop to the top of the tray 270 smoothly.

Embodiment 3

[0062] combine Figure 1-3 As shown, in the above embodiment, a recycling and crushing device for automobile seals also includes a receiving assembly 700, the receiving assembly 700 consists of a box body 710 sleeved on the bottom end of the housing 110 and a The box body 710 is composed of a rotating plate 720 that is movably connected. Two storage cavities are opened on the top of the box body 710. The inside of the housing 110 communicates with the storage cavity near the front side of the housing 110. With this structural design, it can Effectively distinguish qualified and unqualified raw materials.

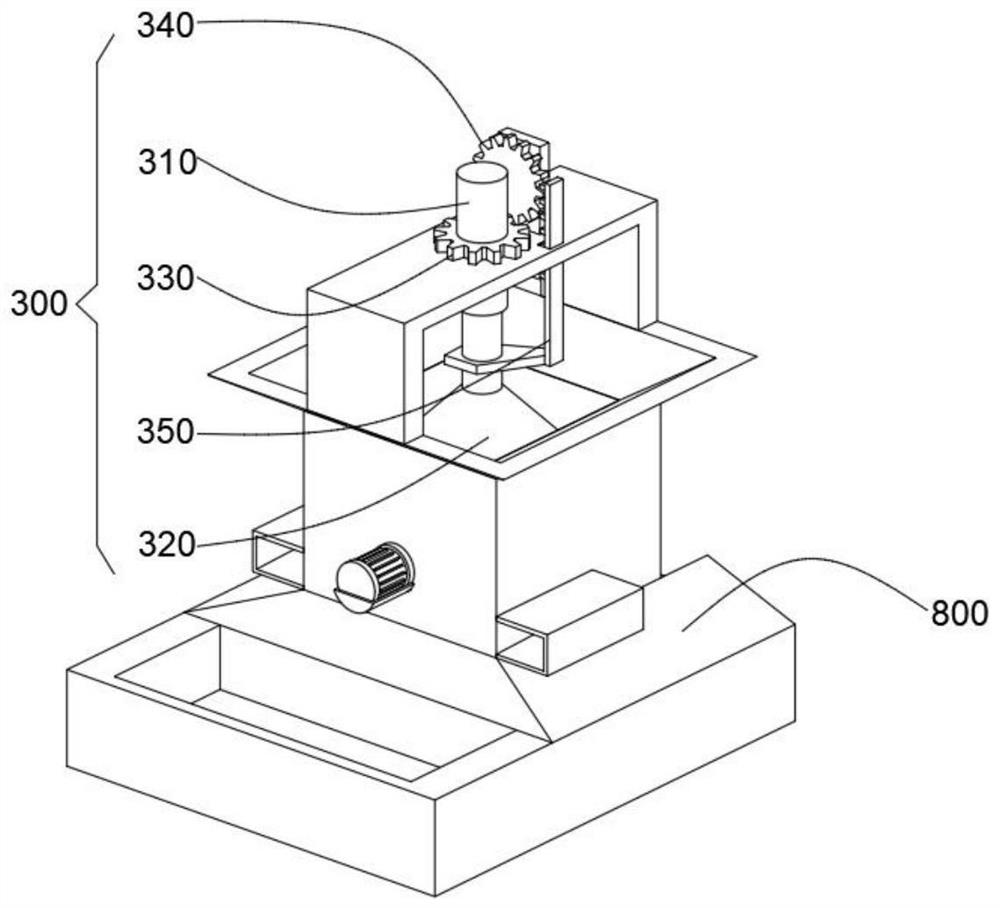

[0063] Further, a cover body 800 is installed between the housing 110 and the box body 710, and the top of the cover body 800 is in contact with the bottom of the frame body 460. Setting the cover body 800 can increase the contact between the housing 110 and the box body 710 The area makes the connection between the housing 110 and the box body 710 more stable.

[0064] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com