Oil field inspection robot based on millimeter-wave radar technology

A millimeter-wave radar and inspection robot technology, applied in the field of robots, can solve the problems of easy impurity adhesion, poor detection effect, and inability to quickly dissipate heat from the internal controller, and achieve the effects of easy blowing and heat dissipation, simple operation, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

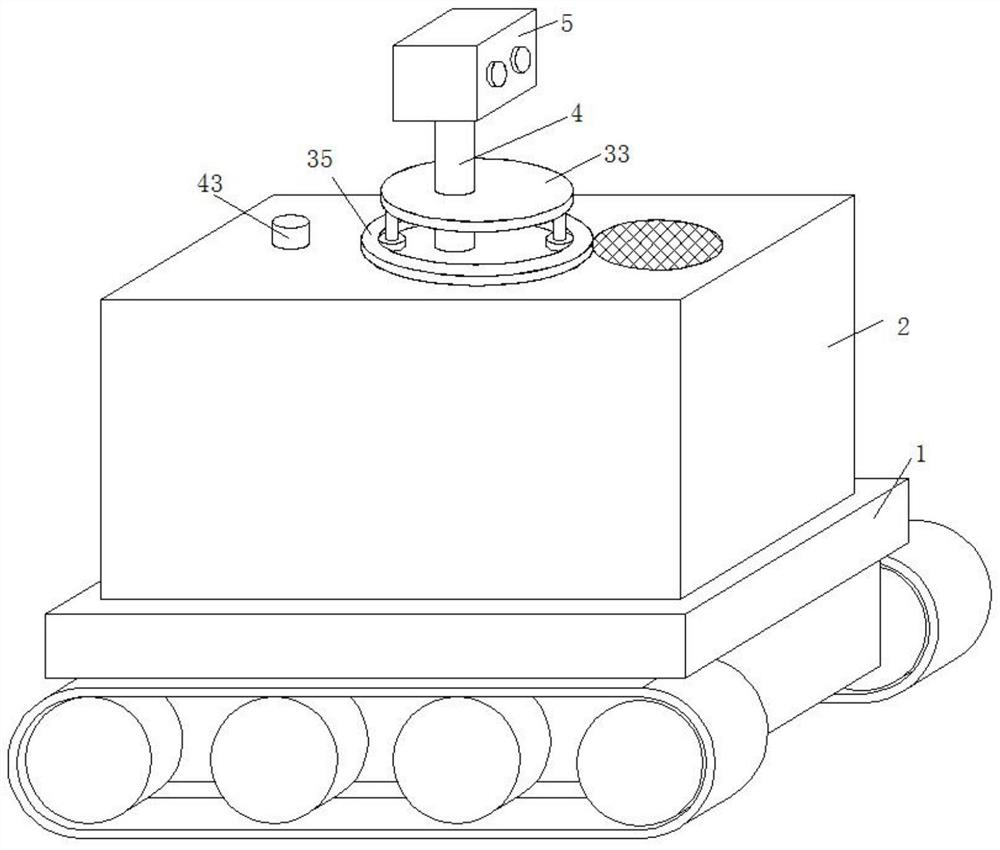

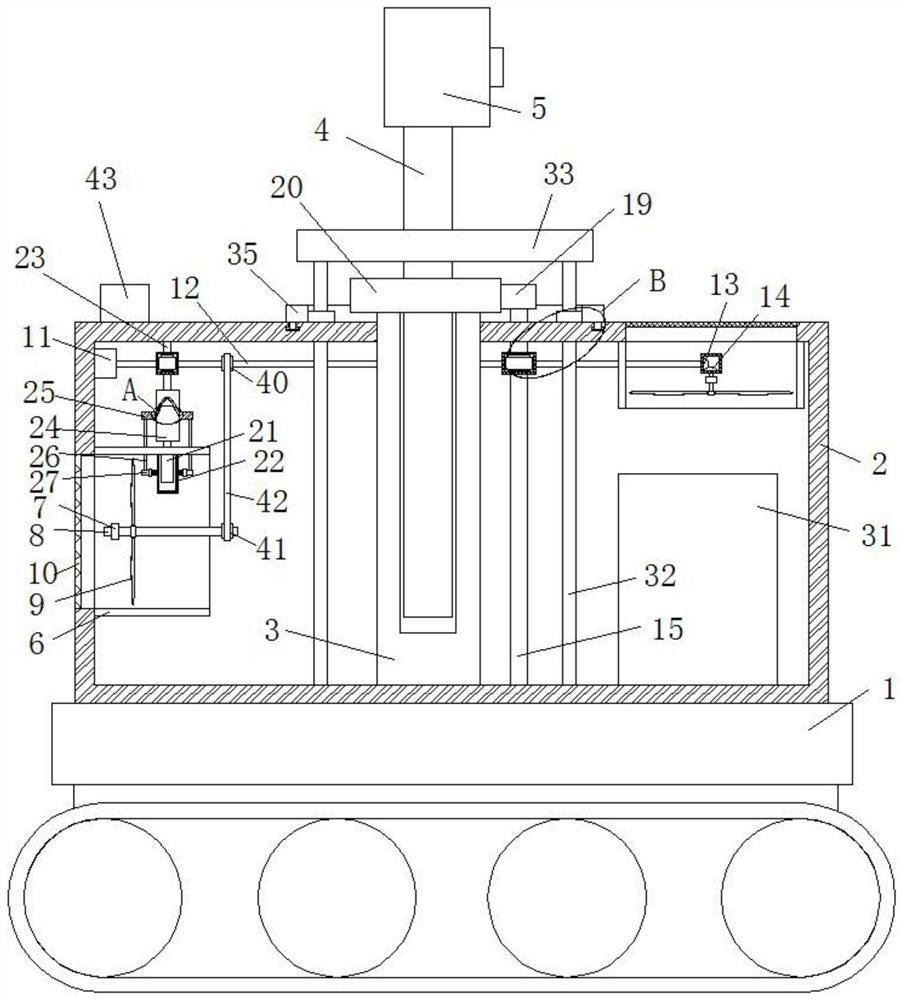

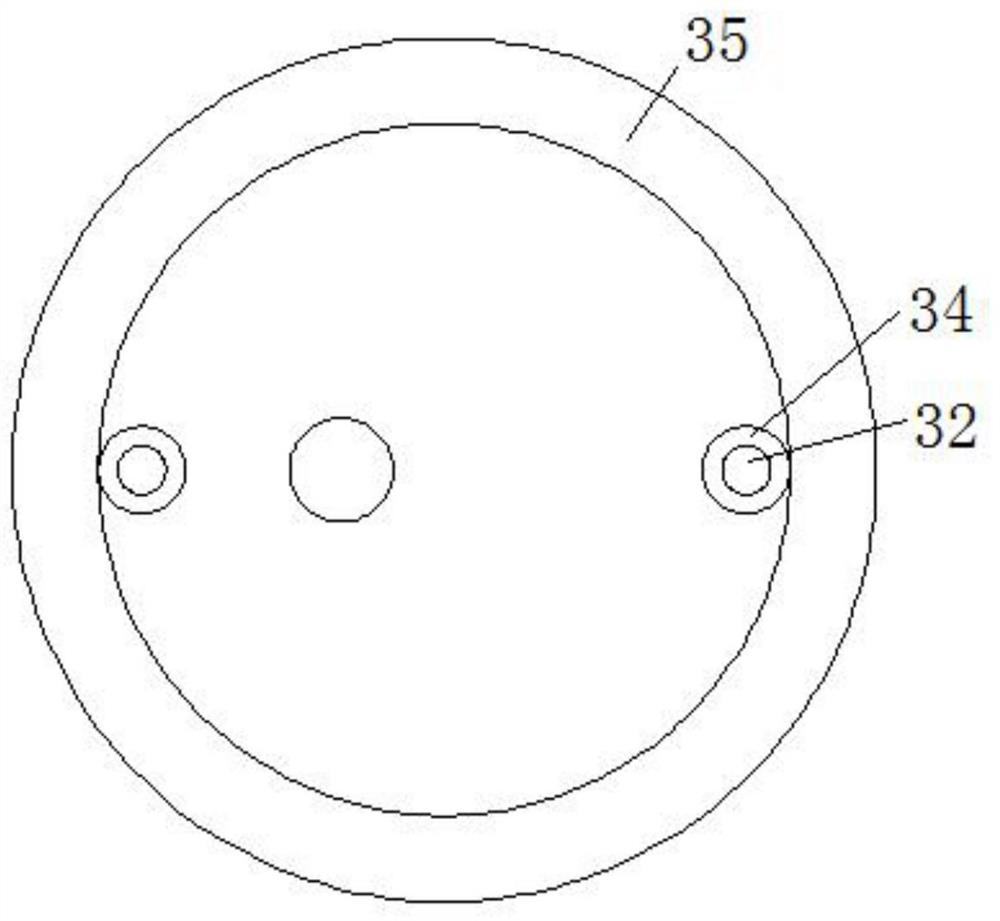

[0023] refer to Figure 1-5 , an oil field inspection robot based on millimeter-wave radar technology, including a body 1, a housing 2 is fixedly installed on the top of the body 1, a positioning column 3 is fixedly installed on the inner wall of the bottom of the housing 2, and a positioning column 3 is movably connected with Support rod 4, camera 5 is fixedly installed on the top of support rod 4, and wind guide box 6 is fixedly installed on the top inner wall and left side inner wall of housing 2, and the inner wall of air guide box 6 is provided with air guide mechanism, and housing A motor 11 is fixedly installed on the inner wall of one side of the motor 11, and a rotating rod 12 is fixedly installed on the output shaft of the motor 11. The rod 12 is connected by transmission, the bottom inner wall of the housing 2 is fixedly installed with a controller 31, the inner wall of the first air guide box 6 of the two air guide boxes 6 is fixedly installed with a detector 21, a...

Embodiment 2

[0029] refer to Figure 1-5 , an oil field inspection robot based on millimeter-wave radar technology, including a body 1, a housing 2 is fixedly installed on the top of the body 1, a positioning column 3 is fixedly installed on the inner wall of the bottom of the housing 2, and a positioning column 3 is movably connected with Support rod 4, camera 5 is fixedly installed on the top of support rod 4, and wind guide box 6 is fixedly installed on the top inner wall and left side inner wall of housing 2, and the inner wall of air guide box 6 is provided with air guide mechanism, and housing A motor 11 is fixedly installed on the inner wall of one side of the motor 11, and a rotating rod 12 is fixedly installed on the output shaft of the motor 11. The rod 12 is connected by transmission, the bottom inner wall of the housing 2 is fixedly installed with a controller 31, the inner wall of the first air guide box 6 of the two air guide boxes 6 is fixedly installed with a detector 21, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com