Cylindrical helical compression spring performance test fixing support

A technology of fixing supports and compressing springs, which is used in elastic testing, mechanical component testing, machine/structural component testing, etc. problems such as damage in the test process, to achieve the effect of complete and reliable test environment, simple and practical installation and connection, and real and reliable test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

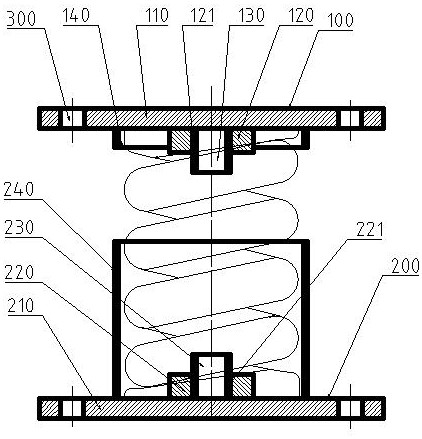

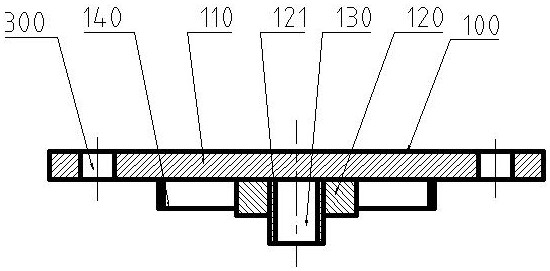

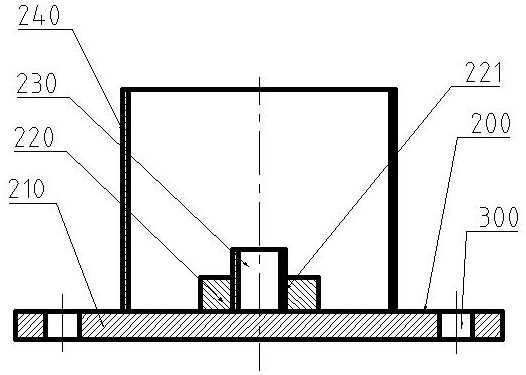

[0022] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments. Such as figure 1 , figure 2 with image 3 , a cylindrical helical compression spring performance test fixed support, including two independent fixed support up and down, the upper fixed support 100 includes a first fixed plate 110, a first limit seat 120, a first axis tube 130 and The upper blocking tube 140, the lower fixing support 200 includes a second fixing plate 210, a second limit seat 220, a second axis tube 230 and a lower blocking tube 240, the first fixing plate 110 and the second fixing Mounting holes 300 are respectively provided on the plate 210, the upper blocking tube 140 is fixed on the first fixing plate 110, the lower blocking tube 240 is fixed on the second fixing plate 210, and the spring is put into the upper In the blocking tube 140 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com