Solution blending equipment for industrial enzyme preparation

A solution and industrial technology, which is applied in the field of solution deployment equipment for industrial enzyme preparation, can solve the problems of equipment internal capacity reduction, inconvenience, and increase cleaning dead angle, etc., to achieve the effect of reducing cleaning dead angle, simple equipment structure, and reducing space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

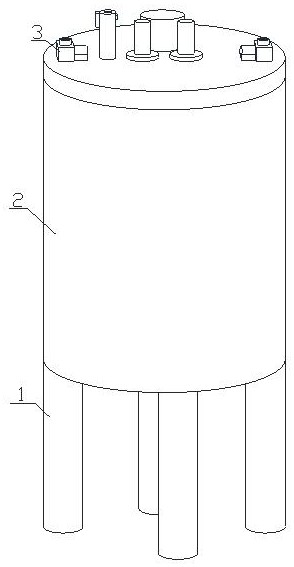

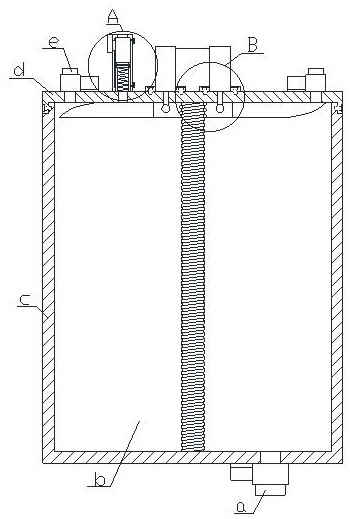

[0024] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a solution preparation equipment for industrial enzyme preparation: its structure includes a supporting foot rod 1, a blending tank 2, an electric control valve 3, the bottom end of the blending tank 2 is fixedly connected with a supporting foot rod 1, and the blending tank 2 is provided with an electric control valve 3;

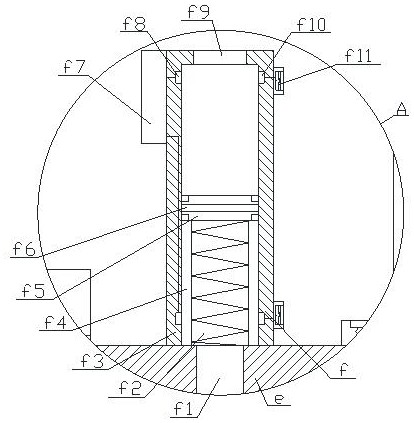

[0025] The blending tank 2 includes a discharge joint a, a blending tank b, a main tank body c, a tank cover d, a feed joint e, a high-pressure warning device f, and a stirring device g. The bottom end of the main tank body c is provided with a discharge Joint a, the inside of the main tank c is equipped with a blending tank b, the top of the main tank c is covered and locked with a tank cover d, and the left and right sides of the top of the tank cover d are provided with feed joints e, so The stirring device g is locked on the tank cover d, and the left side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com