A soil deep mixing process and device for in-situ remediation of organic pollution

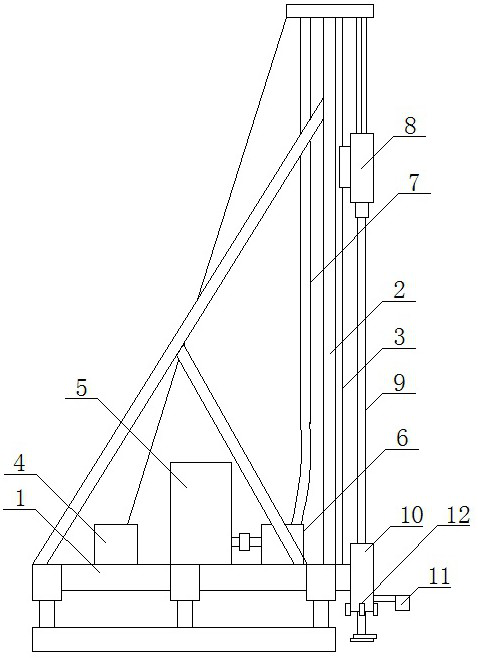

A deep stirring and in-situ repair technology, applied in the field of soil repair, can solve problems such as poor repair effect, and achieve the effects of fast dispersion, uniform dispersion and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The soil deep mixing process for in-situ remediation of organic matter pollution includes the following steps:

[0044] A. Select the plot to be processed, mark the position of the mixing hole, and set the misalignment between two adjacent rows of mixing holes;

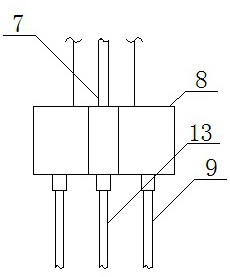

[0045] B. Use the stirring pile to pre-stir and sink the position of the stirring hole, the sinking depth is 2m, and then spray the repair agent into the hole, and continuously stir and rise the stirring pile to the hole opening during the spraying process; then stir and sink to the bottom of the hole , then stir up to the orifice, and repeat the stirring down, stirring up;

[0046] C. Then remove the stirring pile and clean the stirring pile, and then follow step B to operate on the next stirring hole position until all the stirring hole positions are processed.

Embodiment 2

[0048] The soil deep mixing process for in-situ remediation of organic matter pollution includes the following steps:

[0049] A. Select the plot to be processed, mark the position of the mixing hole, and set the misalignment between two adjacent rows of mixing holes;

[0050] B. Use the stirring pile to pre-stir and sink the position of the stirring hole, the sinking depth is 10m, and then spray the repair agent into the hole, and continuously stir and rise the stirring pile to the hole opening during the spraying process; then stir and sink to the bottom of the hole , then stir up to the orifice, and repeat the stirring down, stirring up;

[0051] C. Then remove the stirring pile and clean the stirring pile, and then follow step B to operate on the next stirring hole position until all the stirring hole positions are processed.

Embodiment 3

[0053] The soil deep mixing process for in-situ remediation of organic matter pollution includes the following steps:

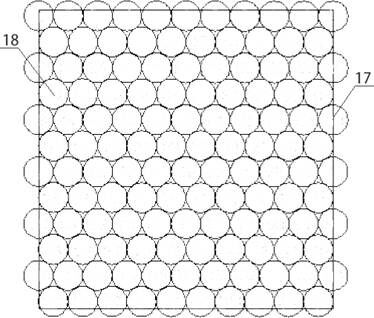

[0054] A. Select the plot to be processed, mark the position of the stirring hole, and set the misalignment between two adjacent rows of stirring holes, and the stirring hole is 5~6 holes / m 2 ;

[0055] B. Use the stirring pile to pre-stir and sink the position of the stirring hole, the sinking depth is 6m, and then spray the repair agent into the hole, and continuously stir and rise the stirring pile to the hole opening during the spraying process; then stir and sink to the bottom of the hole , then stir up to the orifice, and repeat the stirring down, stirring up;

[0056] C. Then remove the stirring pile and clean the stirring pile, and then follow step B to operate on the next stirring hole position until all the stirring hole positions are processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com