Automatic paint spraying device for inner wall of tower drum

A technology of automatic spraying and rotating drive device, which is applied in the direction of spraying device, wind power generation, etc., which can solve the problems of difficulty in achieving uniform spraying on the inner wall of the tower, limited movement range of the nozzle, and large overall structure, etc., to achieve compact overall structure, novel and reliable design , The effect of taking up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

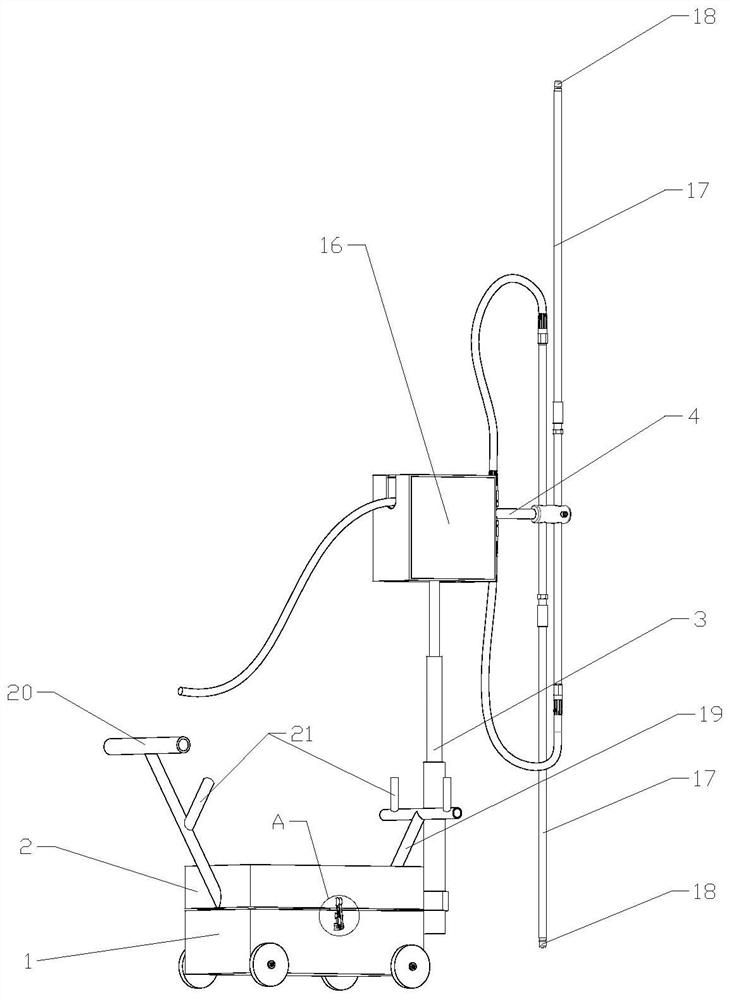

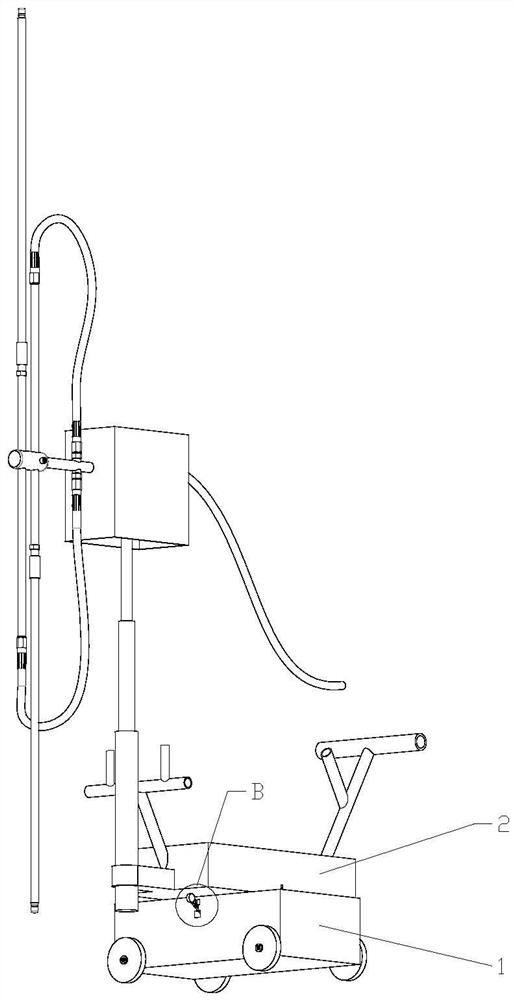

[0041] like Figure 1 to Figure 6 As shown, an automatic spraying device for paint on the inner wall of a tower tube includes an axial traveling device 1, a high-pressure paint filling device, a rotary drive device, a rotating nozzle and a controller, and the controller is used to uniformly control the axial traveling device 1, the high-pressure paint filling device Start and stop of injection device, rotary drive device and rotary sprinkler head.

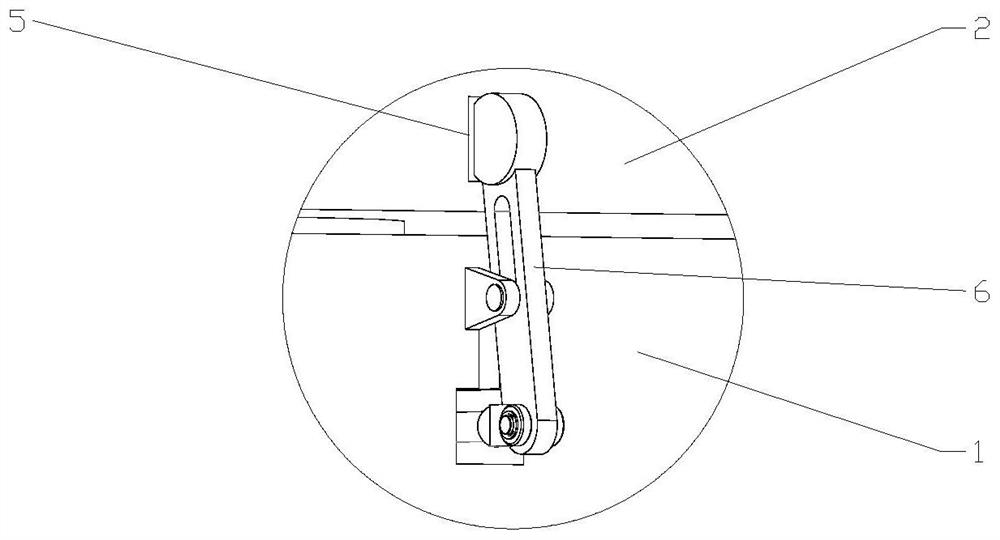

[0042] The upper surface of the axial walking device 1 is equipped with a rotating plate 2 through a rotating mechanism. The rotating mechanism is composed of a telescopic cylinder arranged horizontally, a rack and a gear. The telescopic cylinder reciprocates and expands to drive the rack to reciprocate. Drive the rotary plate 2 to do the rotary motion. A support frame 3 for installing a rotary drive device is arranged on the rotary plate 2 , and a transverse pipe 4 is used to connect the rotary drive device with the rotary sprink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com