Line drawing device and line drawing method for I-steel blanking

A technology of I-beam and line drawing device, applied in manufacturing tools, workshop equipment, etc., can solve the problems of inconsistent cross-sectional size, uneven web, easy deviation, etc. Errors and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

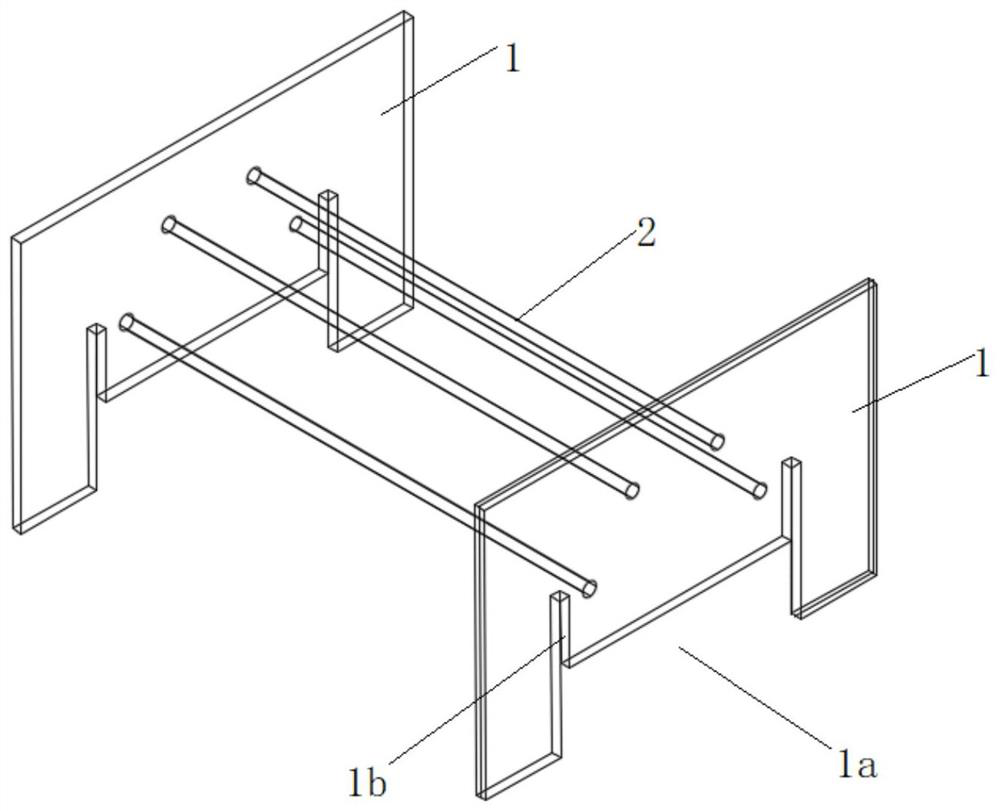

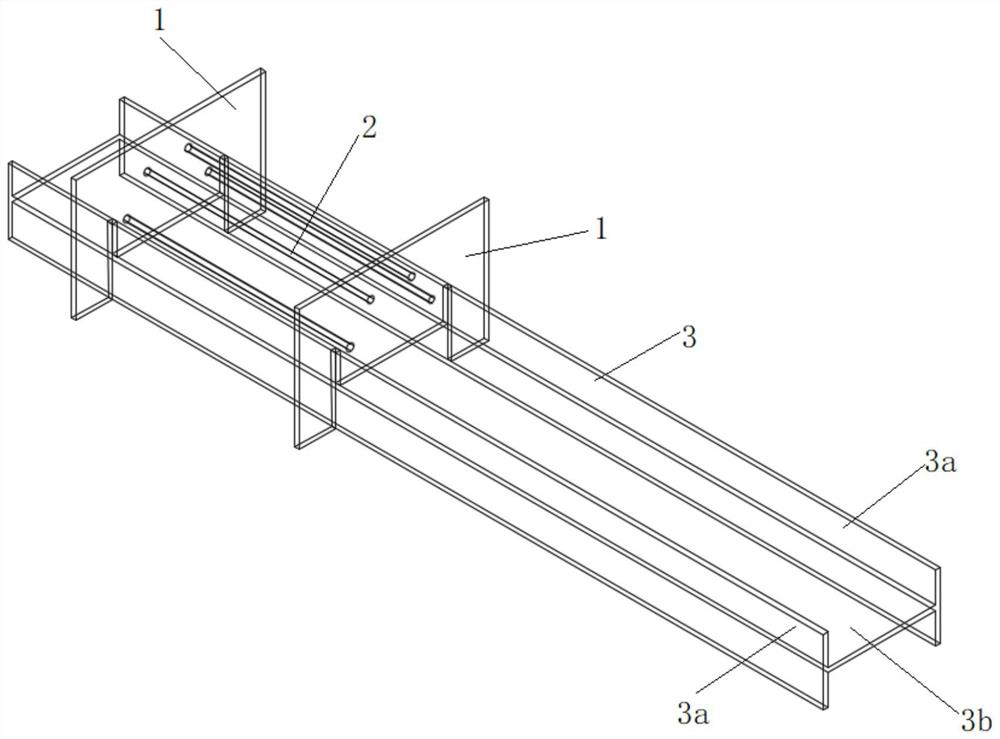

[0018] combine figure 1 — figure 2 As shown, a liner for blanking I-beams is mainly composed of a rigid connecting rod 2 and two vertical clamping plates 1 .

[0019] The two vertical clamps 1 are arranged oppositely, and the two ends of the rigid connecting rod 2 are vertically welded with the vertical clamps 1 respectively to form a whole. The distance between the two rigid connecting plates 1 is determined by the blanking length of the I-beam, and the rigid connecting rod 2 not only serves as a connection, but also serves as a handle for easy operation.

[0020] The middle and lower part of each vertical clamping plate 1 is hollowed out to form a web avoidance area 1a, and wing plate locking grooves 1b extending upward are respectively opened along the left and right edges of the web avoidance area 1a.

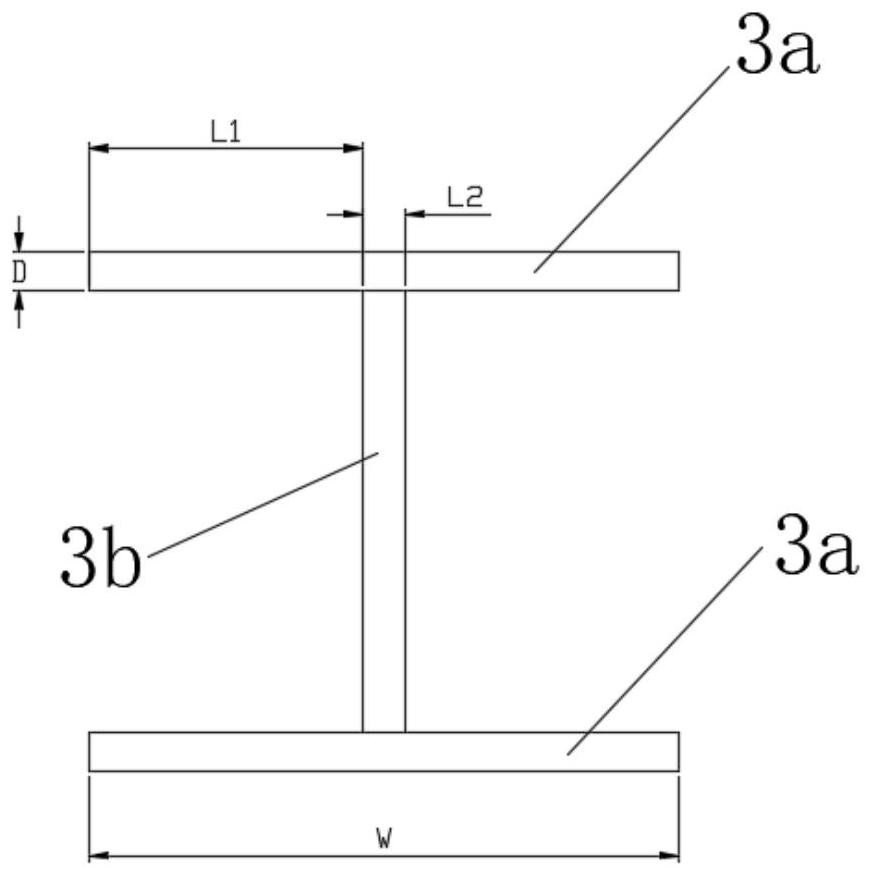

[0021] combine figure 1 — image 3 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com