Emulsion film and preparation method thereof

An emulsion and film technology, applied in the field of emulsion film and its preparation, can solve problems such as poor moisture barrier properties, and achieve the effects of strong anti-oxidation ability, improved stability and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

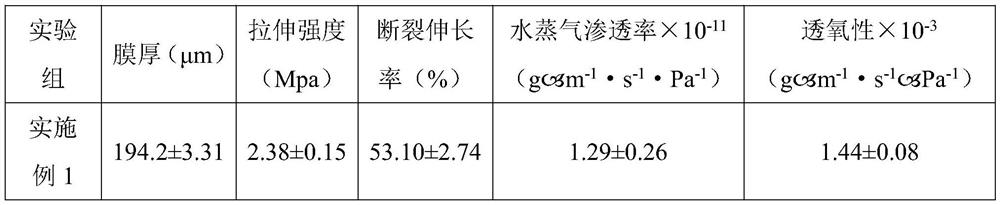

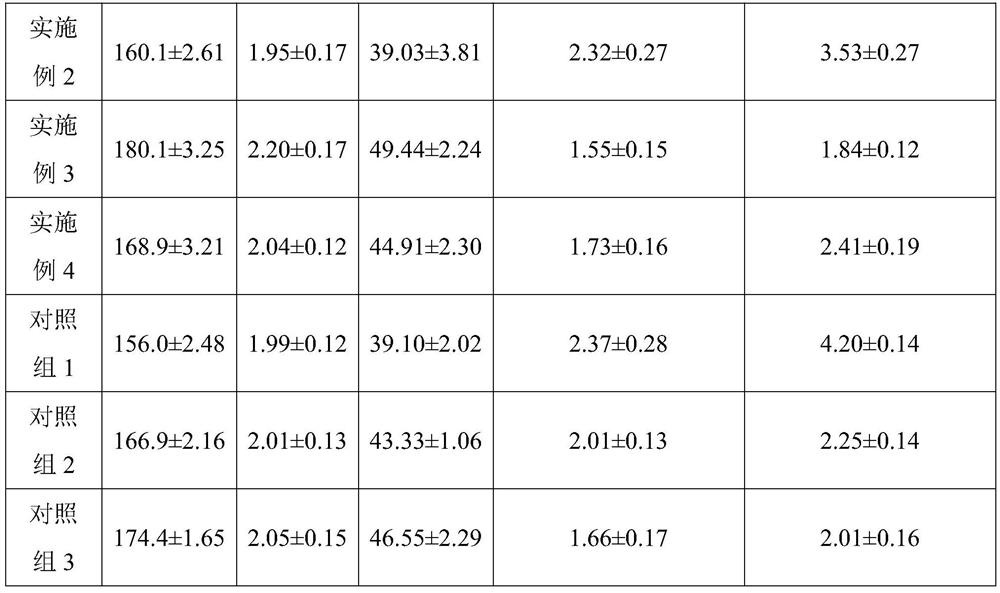

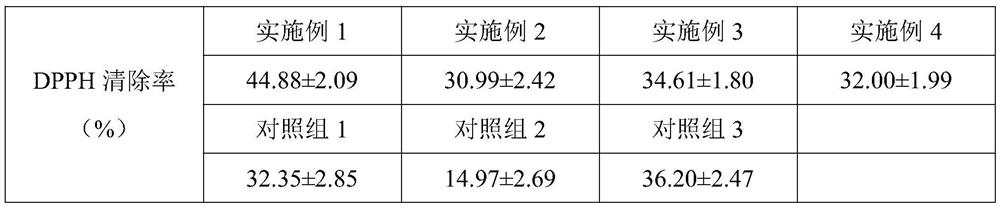

Embodiment 1

[0035] (1) Soak soybeans in deionized water at 4°C for 18 hours at a solid-to-liquid ratio of 1:5 (w / v). Soaked soybeans were ground in a tissue breaker for 8 minutes, wherein the solid-liquid ratio of soybeans to deionized water was 1:9 (w / v). Pass the pulverized mixture through three layers of degreasing gauze to remove the okara, and collect the filtrate. Mix sucrose and filtrate at a ratio of 1:4 (w / v) to liquid, and stir in an ice-water bath for 10 min, adjust the pH value to 7.0 with 1M NaOH, and centrifuge at 25,000×g for 30 min at 4°C to collect the rich The upper creamy layer of soybean oil bodies.

[0036] (2) In order to further purify the soybean oil bodies, dissolve the supernatant collected in step (1) in 20% (w / w) sucrose solution with a solid-liquid ratio of 1:8 (w / v), and adjust the pH value again to 7.0, then centrifuge at 25000×g for 30 min at 4°C to collect the soybean oil bodies in the upper layer, and repeat this step (2) once.

[0037] (3) Dissolve th...

Embodiment 2

[0042] (1) Soak soybeans in deionized water at 4°C for 18 hours at a solid-to-liquid ratio of 1:5 (w / v). Soaked soybeans were ground in a tissue breaker for 8 minutes, wherein the solid-liquid ratio of soybeans to deionized water was 1:9 (w / v). Pass the pulverized mixture through three layers of degreasing gauze to remove the okara, and collect the filtrate. Mix sucrose and filtrate at a ratio of 1:4 (w / v) to liquid, and stir in an ice-water bath for 10 min, adjust the pH value to 9.0 with 1M NaOH, and centrifuge at 25,000×g for 30 min at 4°C to collect the rich The upper creamy layer of soybean oil bodies.

[0043] (2) In order to further purify the soybean oil bodies, dissolve the supernatant collected in step (1) in 20% (w / w) sucrose solution with a solid-liquid ratio of 1:8 (w / v), and adjust the pH value again to 9.0, then centrifuge at 25,000×g for 30 min at 4°C to collect the soybean oil bodies in the upper layer, and repeat this step (2) once.

[0044] (3) Dissolve t...

Embodiment 3

[0049] (1) Soak soybeans in deionized water at 4°C for 18 hours at a solid-to-liquid ratio of 1:5 (w / v). Soaked soybeans were ground in a tissue breaker for 8 minutes, wherein the solid-liquid ratio of soybeans to deionized water was 1:9 (w / v). Pass the pulverized mixture through three layers of degreasing gauze to remove the okara, and collect the filtrate. Mix sucrose and filtrate at a ratio of 1:4 (w / v) to liquid, and stir in an ice-water bath for 10 min, adjust the pH value to 11.0 with 1M NaOH, and centrifuge at 25,000×g for 30 min at 4°C to collect the rich The upper creamy layer of soybean oil bodies.

[0050] (2) In order to further purify the soybean oil bodies, dissolve the supernatant collected in step (1) in 20% (w / w) sucrose solution with a solid-liquid ratio of 1:8 (w / v), and adjust the pH value again to 11.0, then centrifuge at 25000×g for 30 min at 4°C to collect the soybean oil bodies in the upper layer, and repeat this step (2) once.

[0051] (3) Dissolve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com