Double-fan pressurized air supply system and working method

A technology of air supply system and double fan, which is applied in the direction of ventilation system, heating and ventilation control system, heating and ventilation safety system, etc. It can solve the problems of large size of pressurized blower, large power consumption, high power of pressurized blower, etc. Achieve the effect of prolonging the continuous working time and avoiding paralysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

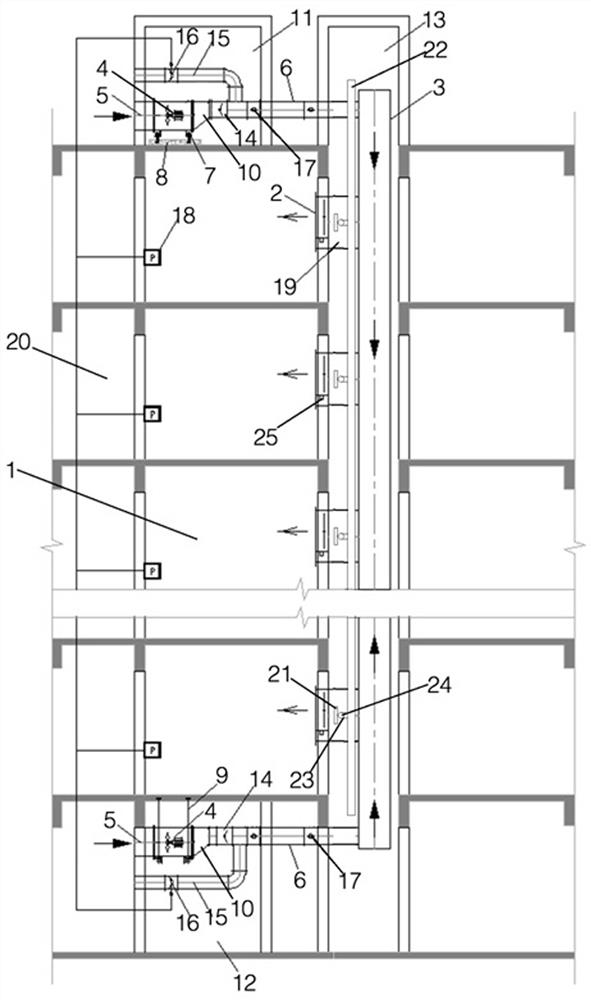

[0043] like figure 1 Shown, the present embodiment is a kind of double fan pressurized air supply system, comprises building roof machine room 11, building basement machine room 12 and building pipe well 13, is provided with air pipe 3 in building pipe well 13, and air pipe 3 is connected from building pipe well 13 The top extends vertically downwards to the bottom of the building tube well 13; the side wall of the service object space 1 inside the building is provided with a pressurized air supply port 2 communicating with the air duct 3; in this embodiment, the service object space 1 inside the building is the interior of the building The front room of each floor; the pressurized air outlet 2 is a normally closed air outlet;

[0044] The computer room 11 on the roof of the building and the computer room 12 in the basement of the building are respectively provided with a pressurized blower 4, the air inlet of the pressurized blower 4 communicates with the outside, and the ai...

Embodiment 2

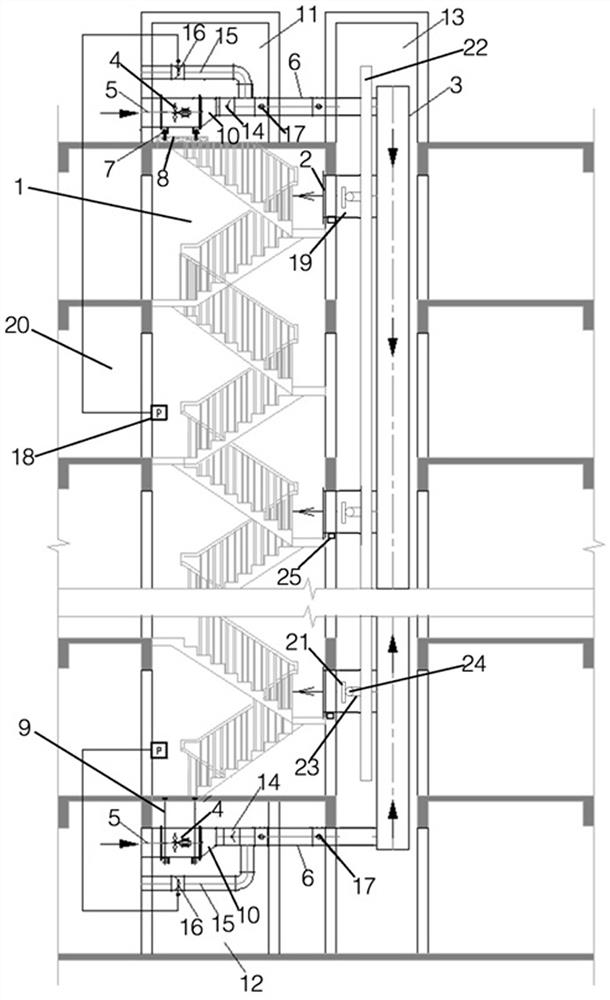

[0065] like figure 2 As shown, this embodiment is a dual-fan pressurized air supply system. This embodiment is similar to Embodiment 1, the only difference is that in this embodiment, the service object space 1 inside the building is the stairwell inside the building; because the stairs The room is connected up and down. Compared with the traditional air supply method with only one pressurized blower 4, the double-fan pressurized air supply system in this embodiment can make the air volume distribution in the stairwell more uniform and make the positive pressure value in the stairwell faster. When the set value is reached; when the double-fan pressurized air supply system supplies air to the stairwell, the pressurized air supply port 2 is a normally open air port; the pressurized air supply port 2 is always open and does not need to be installed on each floor. It only needs to be installed on odd-numbered or even-numbered floors, and the pressure detector 18 does not need to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com