Can production tool, process for controlling can weight, cost, and dimensions

A technology of tools and dimensions, applied in the field of can making tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0181] Glossary

[0182] As used herein, the term "material to be ground (grind stock)" refers to the number of new tools and wear of grinding tools can be used, and usually refers to an area storing tools workshop tools.

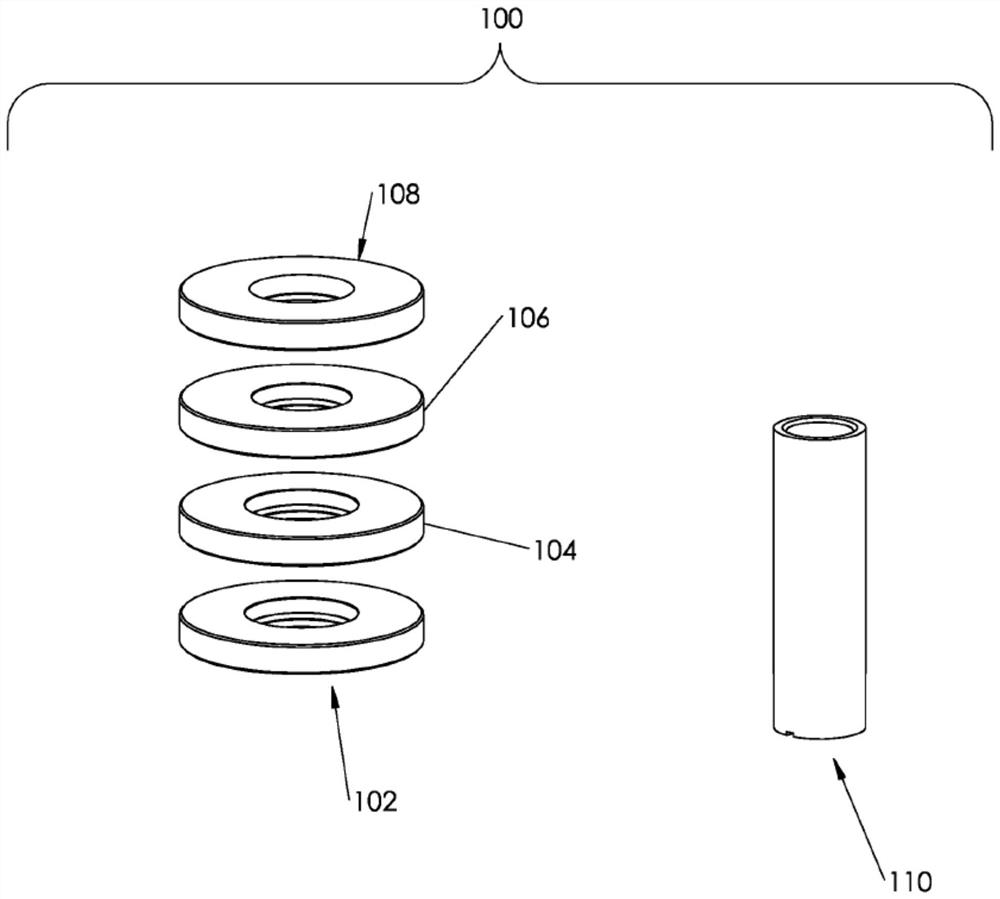

[0183] The term "dimension check (size inspection)" refers to a throwaway tool to ensure that the exact dimensions desired for a given set of tools, and mark the exact dimensions of the new tool. This tool will produce "relevant diameter (associated diameter)": Learn diameter of the tool is essential for proper production. Since the tools of various sizes, in fact, have a "more relevant diameter" tool in most groups, e.g., image 3 or Figure 7 Different diameters shown.

[0184] As used herein, the term "tool (Tool)" means at least one die for the production of a cylindrical body such as a can or the like, or punch.

[0185] The term "tool set (tool set)" refers to a group having a very close correlation dimension (e.g. image 3 Die shown) in / punch, and it may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com