Intelligent welding trolley for outfitting welding of ship hatch cover

A technology for welding trolleys and hatch covers, which is used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to reduce human dependence and avoid influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

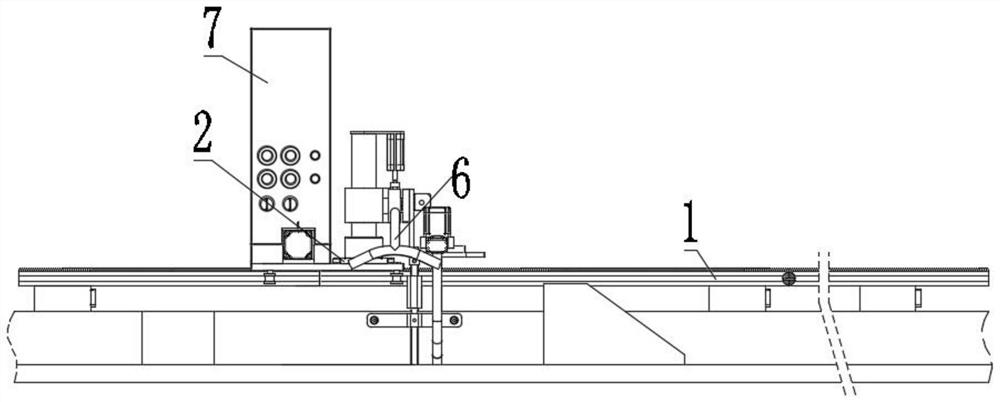

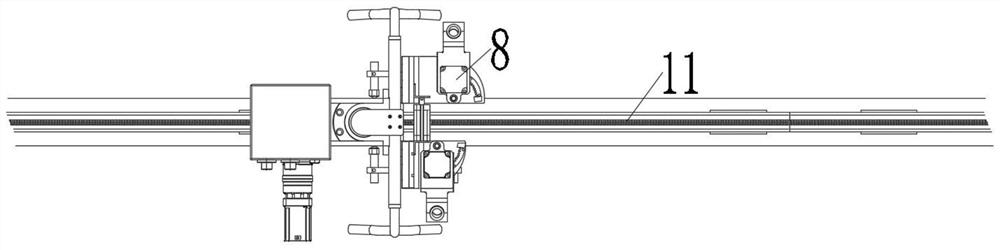

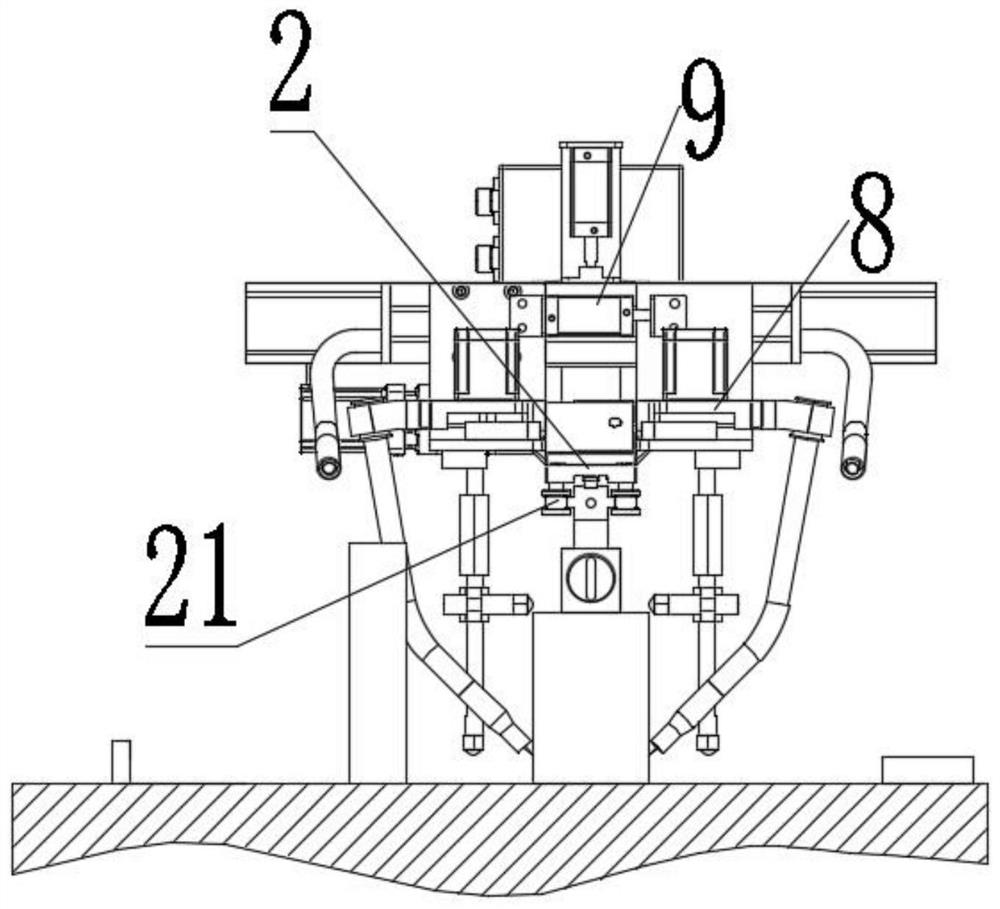

[0027] Please refer to the attached Figure 1-6 , shows an intelligent welding trolley for ship hatch outfitting welding provided by an embodiment of the present application, including a slide rail structure 1 fixedly connected to the ship to be welded, and the track of the slide rail structure 1 is in line with the hull The side of the slide rail structure 1 is slidably connected to the sliding seat 2, the sliding seat 2 can be slidably connected to the slide rail structure 1, the top of the sliding seat 2 is fixedly connected to the support column 3, and the side of the support column 3 is slidably connected There is a sub-frame body 4, a control cylinder one 5 is connected between the sub-frame body 4 and the top of the support column 3, and the control cylinder one 5 drives the sub-frame body 4 to move up and down, and the card side of the sub-frame body 4 is provided with a transverse slideway, Two groups of main frames are slidingly connected to the front side of the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com