Automatic pipe cutting machine

A pipe cutting machine and automatic technology, which is applied in metal processing and other directions, can solve the problems of affecting the airtightness of the connection, poor product uniformity, and low clamping stability, so as to improve the airtightness of the connection and realize mass production , to avoid the effect of hose deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

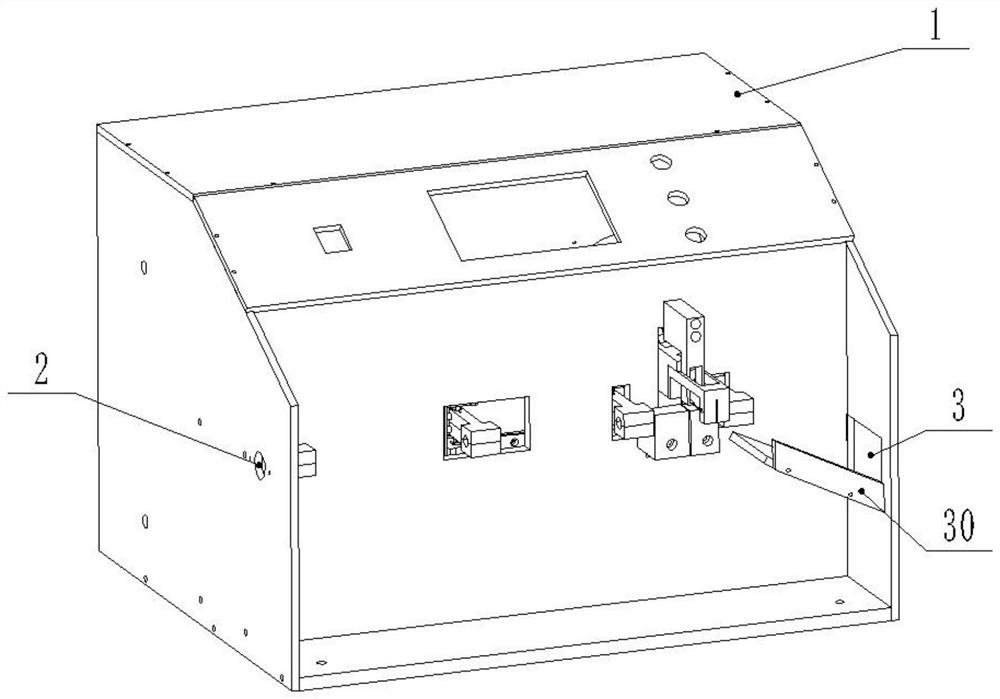

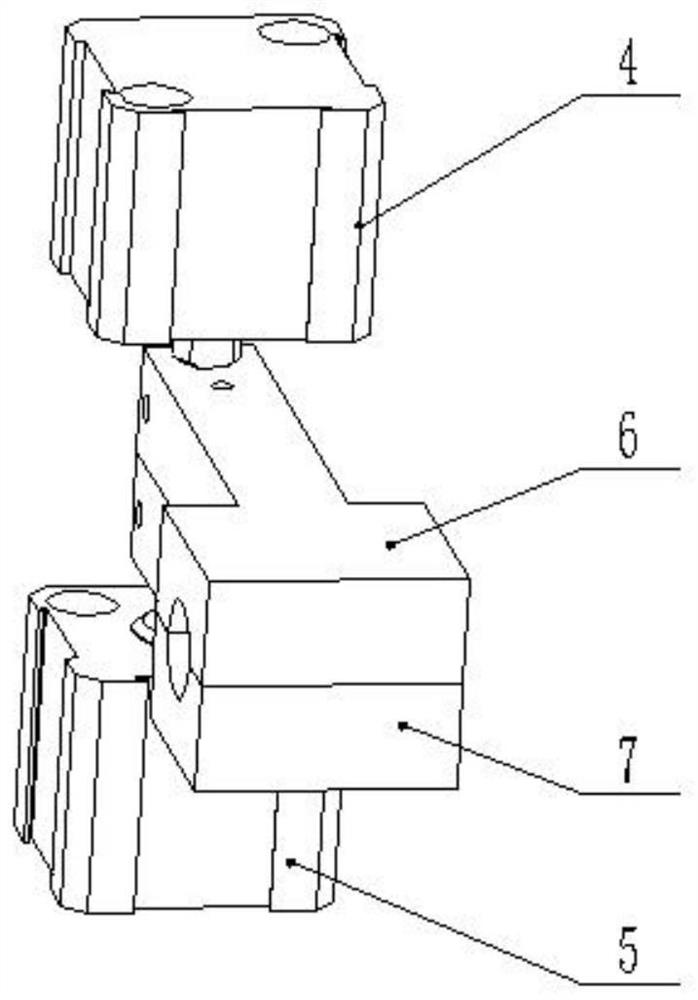

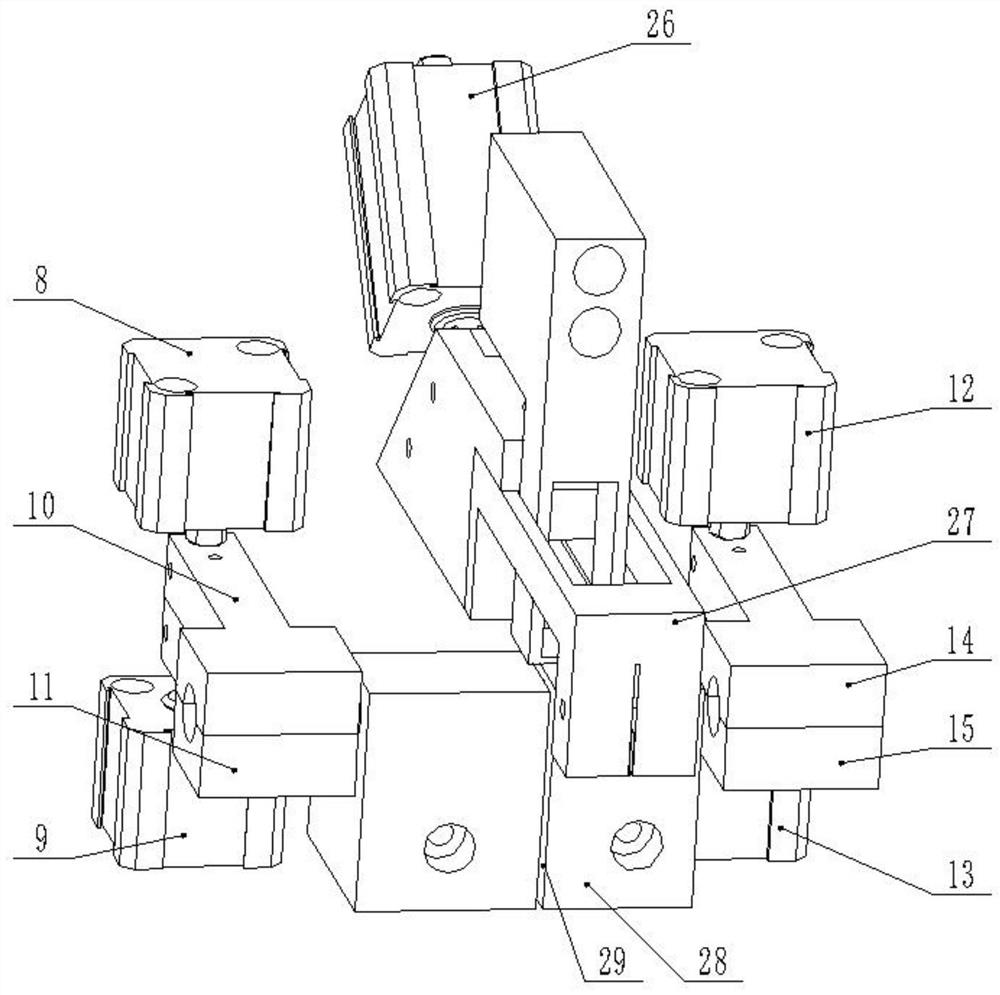

[0024] like Figure 1-4 As shown, a kind of automatic pipe cutting machine of the present invention comprises a chassis 1, one side of the chassis 1 forms a feed port 2, and the other side of the chassis 1 forms a discharge port 3; the interior of the chassis 1 is provided with a first clamping mechanism , the transmission mechanism, the second clamping mechanism, the third clamping mechanism and the cutting mechanism; the first clamping mechanism, the second clamping mechanism and the third clamping mechanism clamp the pipe at the same level, and the first clamping mechanism is close to the feeding port 2. The third clamping mechanism is close to the discharge port 3, the transmission mechanism is located between the first clamping mechanism and the secon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap