Lightweight rapid battery replacement frame assembly and method for integrally replacing battery

A frame assembly and lightweight technology, which is applied to battery pack components, circuits, charging stations, etc., can solve the problems of low battery replacement efficiency, complex and cumbersome separation steps of battery frame assembly and vehicle frame, and insufficient charging time, etc. problem, to achieve the effect of simple operation, improved power exchange efficiency, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

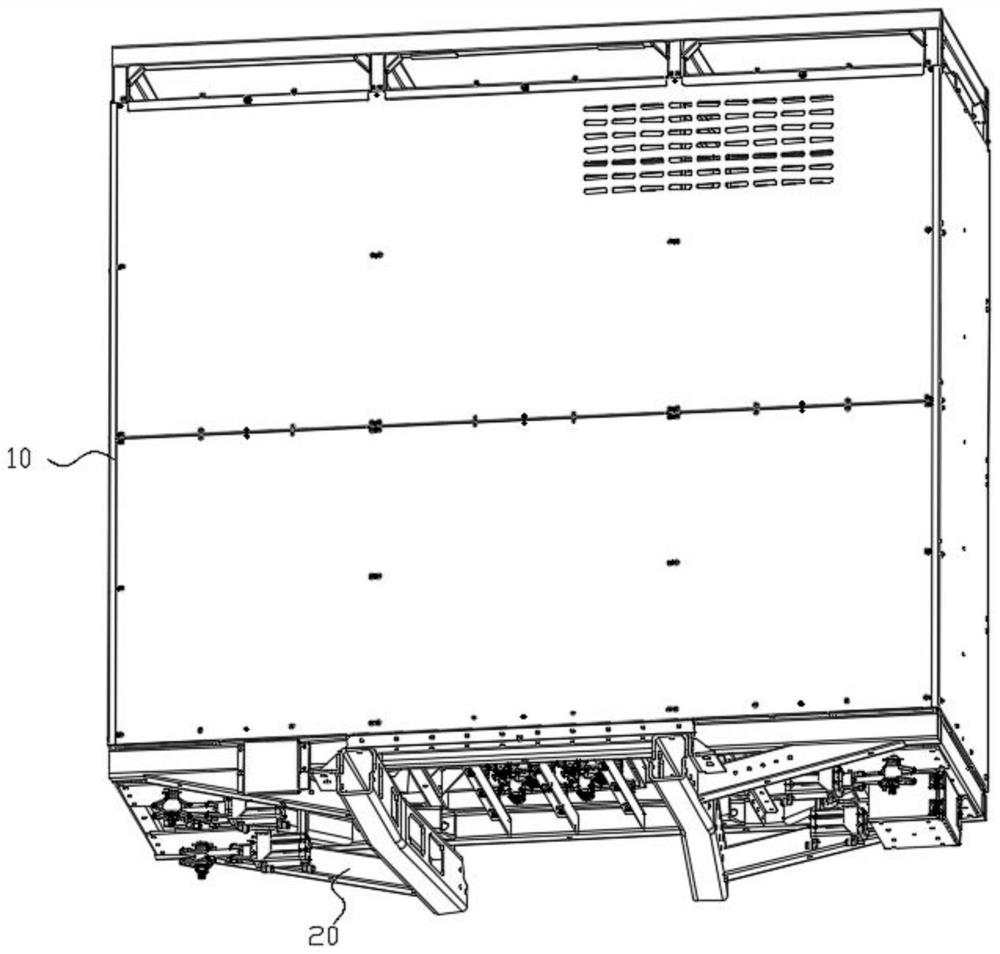

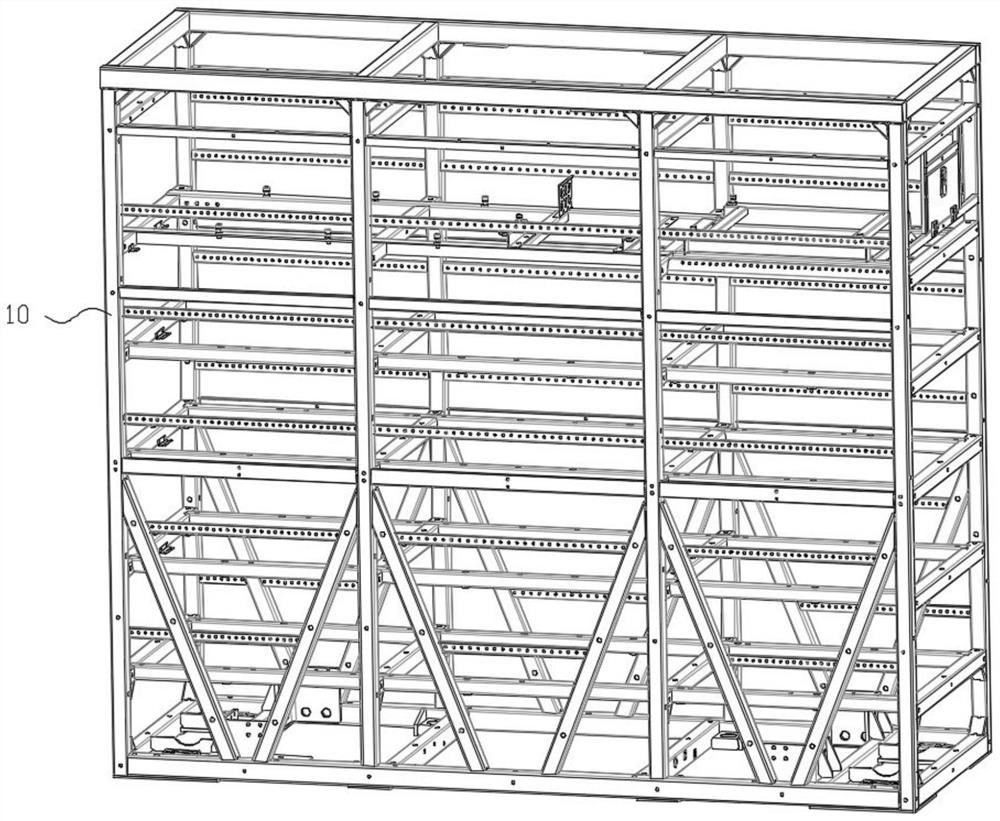

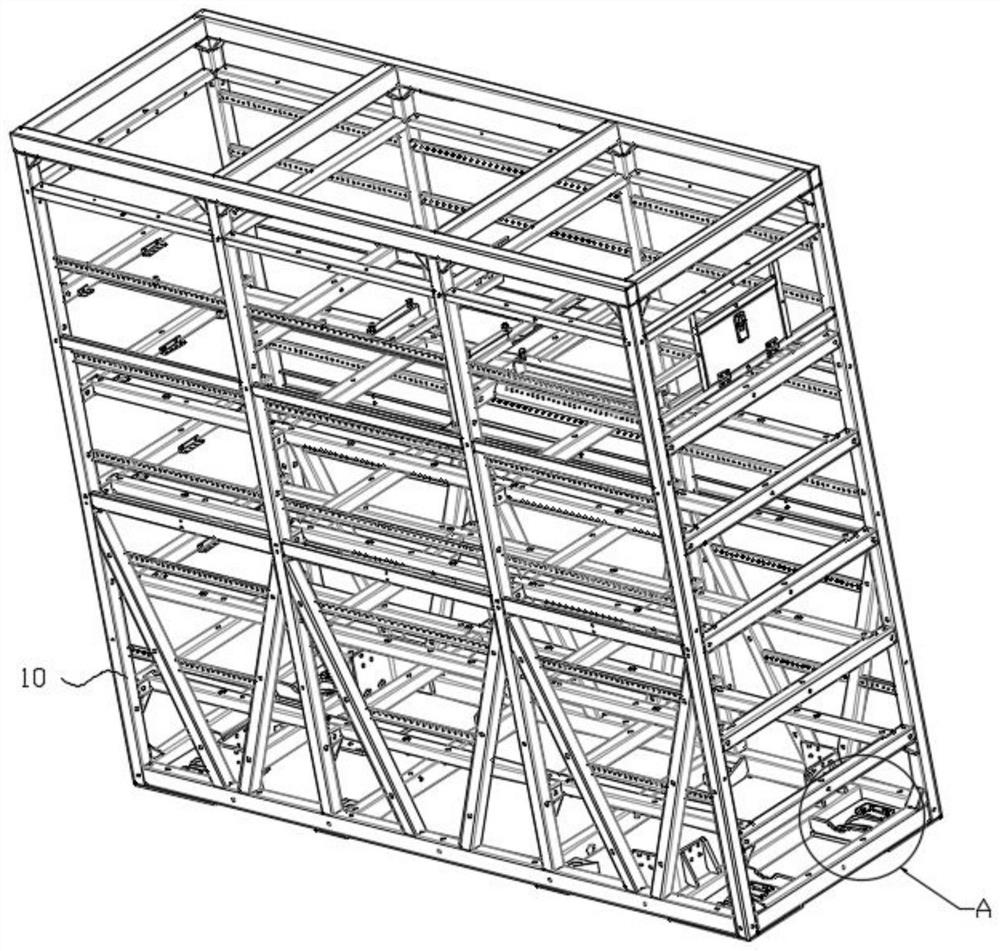

[0038] Example: such as Figure 1 to Figure 7 As shown, a light-weight quick-change battery frame assembly includes a battery integrated fixing frame 10. Several battery compartments for installing batteries are arranged on the battery integrated fixing frame 10, and a protective cover and a protective cover are arranged on the outside. The observation port on one side of the cover also includes a frame installation control frame 20 arranged below the integrated battery fixing frame 10 .

[0039] The frame installation control frame 20 is equipped with a quick release mechanism and a positioning mechanism;

[0040]The quick release mechanism includes a drive member 21 (preferably an air cylinder) installed on the frame installation control frame 20, a rotating clamping pin 22 mounted on the frame installation control frame 20, and two ends are connected with the output end of the drive member 21 and the rotation pin respectively. The clamping pin 22 is rotatably connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com