Preparation method of short rod-like aramid nanofiber, aramid nanofiber and application

A technology of nanofibers and para-aramid fibers, which is applied in nanotechnology, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of shortening the reaction cycle, environmental pollution of organic solvents, and low output, and achieve shortening of the reaction cycle and operation Convenience and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

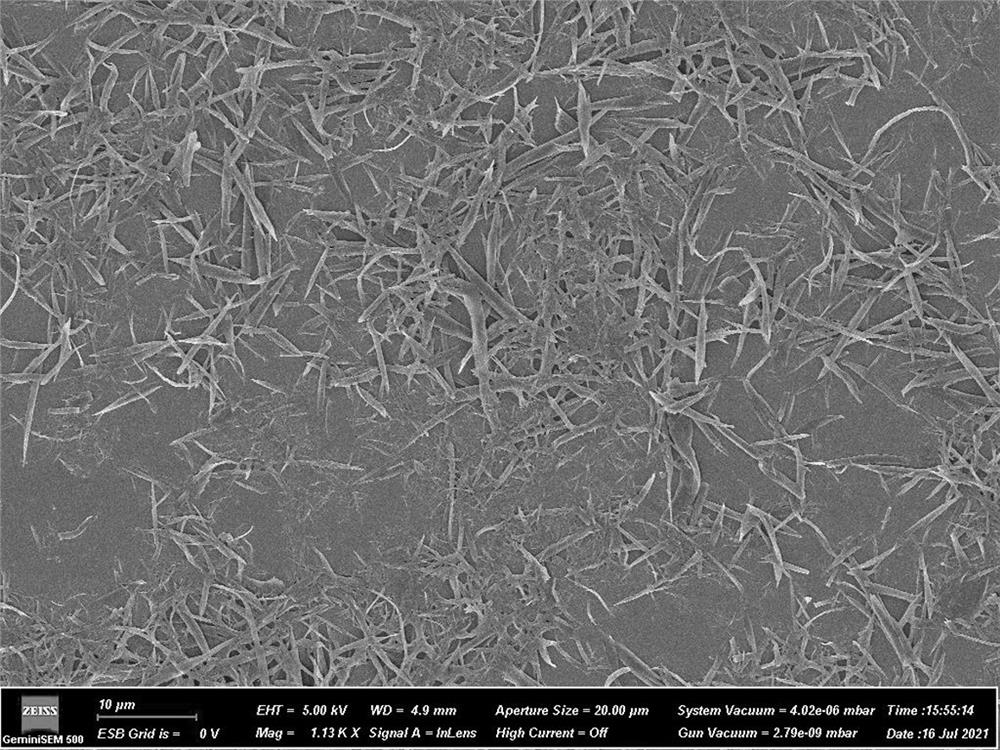

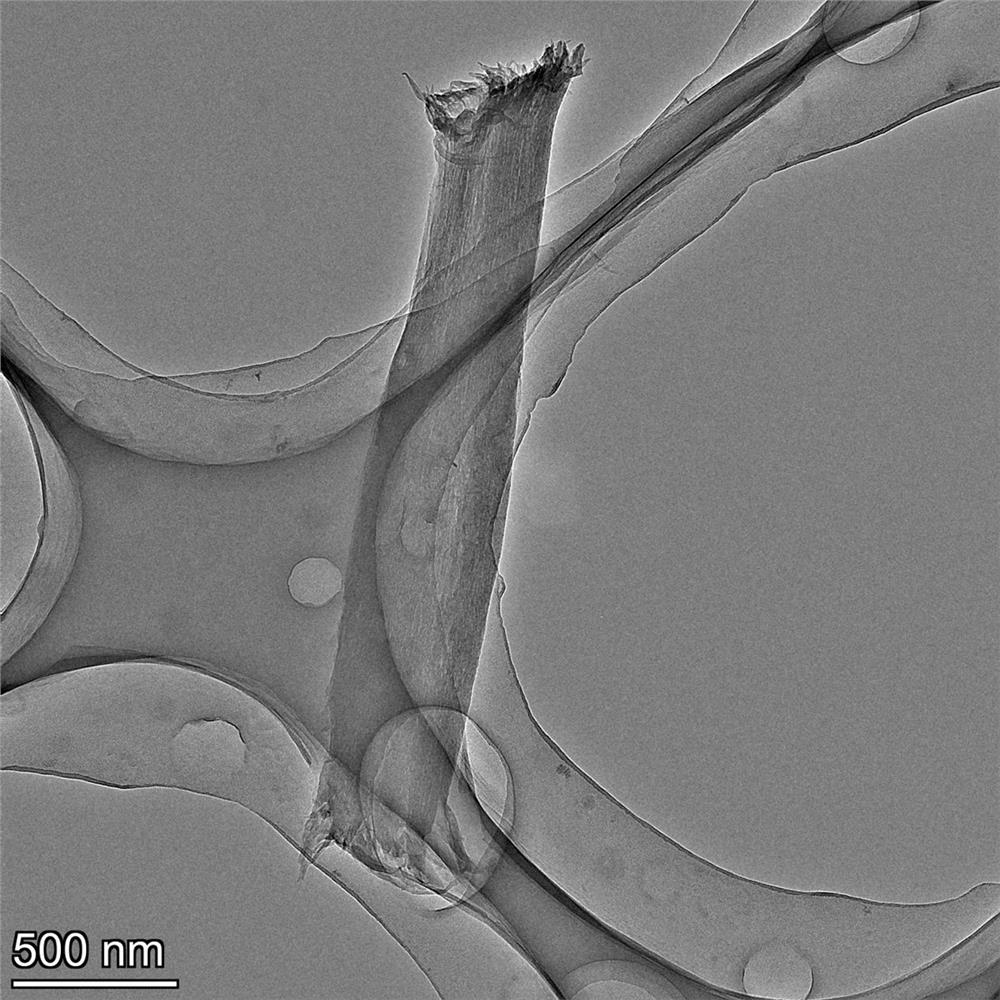

[0026] A preparation method of short rod-shaped aramid fiber, comprising the following steps:

[0027] (1) Put 20g of absolutely dry para-aramid fiber with an average length of 3mm into a beaker, add water to 200g, mix evenly and add it to a PFI beater, and the beating speed is 5000r to obtain para-aramid fiber A;

[0028] (2) Take 1g of para-aramid fiber A, add 50mL of water into a beaker with 5gKOH, place the beaker in a water bath, and stir with the aid of a stirrer to obtain para-aramid fiber dispersion A; the processing conditions are: water bath The temperature is 80°C, the rotation speed of the agitator is 500r, and the treatment time is 3h;

[0029] (3) Vacuum filter the para-aramid fiber dispersion A obtained in step (2) to a pH of 8 to obtain para-aramid fiber dispersion B;

[0030] (4) Put the para-aramid fiber dispersion B obtained in step (3) into the steam explosion feeding bin and explode to obtain a short rod-shaped aramid nanofiber aqueous solution, and obtai...

Embodiment 2

[0032] A preparation method of short rod-shaped aramid fiber, comprising the following steps:

[0033] (1) Put 20g of absolutely dry para-aramid fiber with an average length of 1mm into a beaker, add water to 200g, mix evenly and add it to a PFI beater, and the beating speed is 10000r to obtain para-aramid fiber A;

[0034] (2) Take 1g of para-aramid fiber A, add 10g of KOH to 50mL of water in a beaker;

[0035] (3) Place the beaker containing the para-aramid fiber and KOH solution system obtained in step (2) in a water bath, and stir with the aid of a stirrer to obtain para-aramid fiber dispersion A; the treatment conditions For: the temperature of the water bath is 80°C, the rotation speed of the agitator is 500r, and the treatment time is 3h;

[0036] (4) Vacuum filter the para-aramid fiber dispersion A obtained in step (3) to a pH of 8 to obtain para-aramid fiber dispersion B;

[0037] (5) Put the para-aramid fiber dispersion B obtained in step (4) into the steam explosi...

Embodiment 3

[0039] A preparation method of short rod-shaped aramid fiber, comprising the following steps:

[0040] (1) Put 20g of absolutely dry para-aramid fiber with an average length of 1mm into a beaker, add water to 200g, mix evenly and add it to a PFI beater, and the beating speed is 20000r to obtain para-aramid fiber A;

[0041] (2) Take 1g of para-aramid fiber A, add 20g of KOH to 50mL of water in a beaker;

[0042] (3) Place the beaker containing the para-aramid fiber and KOH solution system obtained in step (2) in a water bath, and stir with the aid of a stirrer to obtain para-aramid fiber dispersion A; the treatment conditions For: the temperature of the water bath is 80°C, the rotation speed of the agitator is 500r, and the treatment time is 3h;

[0043] (4) Vacuum filter the para-aramid fiber dispersion A obtained in step (3) to a pH of 8 to obtain para-aramid fiber dispersion B;

[0044] (5) Put the para-aramid fiber dispersion B obtained in step (4) into the steam explosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com