Building foundation pit supporting structure with damping structure

A foundation pit support and construction technology, which is used in construction, infrastructure engineering, sheet pile walls, etc. The effect of increased tightening force and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

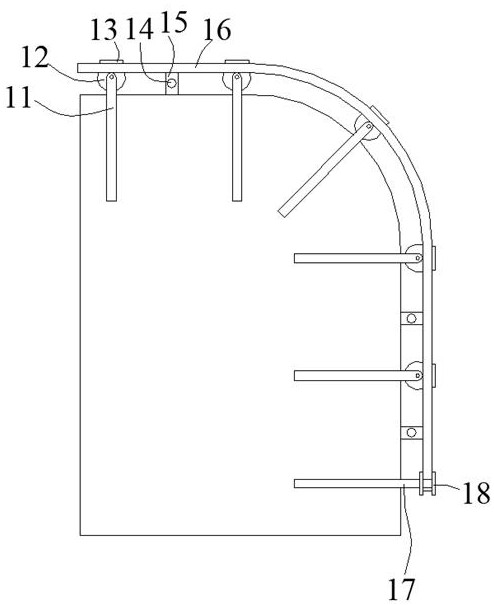

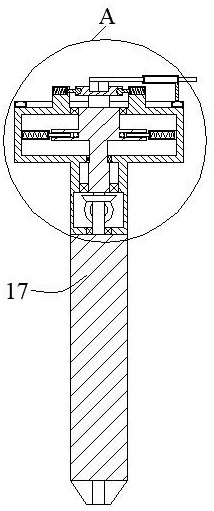

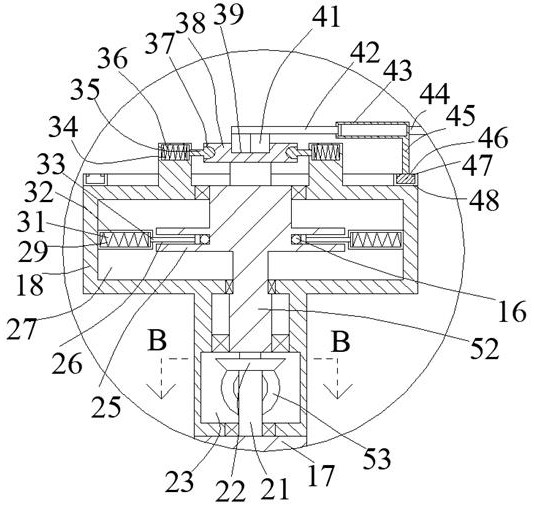

[0024] Such as Figure 1-Figure 9 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship are consistent. A building foundation pit support structure with a shock absorbing structure of the present invention includes several strip-shaped stay ropes 16, and the lower side of the stay ropes 16 is provided with a locking block 15. The locking block 15 is provided with a matching rope 14 perpendicular to the pull rope 16, the matching rope 14 and the pulling rope 16 form a mesh structure, and the ends of the pulling rope 16 and the matching rope 14 are provided with a matching box body 18, the stay rope 16 and the matching rope 14 extend into the matching box 18 for winding, and one side of the matching box 18 is provided with a rotating drilling rod 17, and the pulling rope 16 and the match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com